SPRINGING OF COMMERCIAL MOTORS.

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

The Choice of Materials for Spring Making. The Question of Camber. The Lubrication of the Leaves and the Best Mode of Preventing them from Sliding Out.

By Sydney S. Guy (Managing Director, Guy Motors, Ltd.).

IWAS more than usually interested in the article which appeared in The Commercial Motor of April 25th dealing with the springing of commercial motor vehicles and based upon the contentions advanced by Messrs. J. I. Thornycroft and Co., Ltd. Whilst I am pleased to see that commercial vehicle manufacturers are commencing to give greater attention to the springing of their vehicles than has been general in the past, still, at the same time, there are several points in the article referred to on which I should like to comment. Dealing first of all with the question of the right material to be used in manufacturing springs. I could not for a moment agree that the old-fashioned plain earbon steel spring is capable of holding its own with the alloy steel spring, as, with springs made from a suitable alloy, my experience has been that they are far less likely to fracture from fatigue. Moreover, to carry the Make load, with an alloy steel spring, one can work with a lighter spring than with a carbon steel spring, because the former type will stand a greater stress, and, further, without making the spring unduly heavy, it can be designed in alloy steel to work at a great deflection, which, naturally, gives easier riding. However, it. would be very interesting to hear the views of some spring manufacturers on this point. With regard to a spring to be flat in its loaded position. It is, of course, generally accepted that the nearer one can approach to a flat Spring in a, loaded position the. better. There is, however, a point to consider in connection with a perfectly flat spring, namely, that, when it is further depressed owing to inequalities in the road surface, or the inevitable overloading which occurs, the spring will, naturally, have a reverse camber and in our experience it is very difficult to persuade the average user that all is well. With reference to the movement of Messrs. Thornycroft's spring from their B.T. chassis, it would appear that, although you state under the heading of "Qualities of Good Springing" that the fundamental need is flexibility, still the ease of the spring under review, which has a deflexion of only 2 ins. between its free and fully laden position, rather goes to show that it is not a very flexible spring, and as the deflection is so small, possibly a carbon steel spring would give satisfactory results, but, in my opinion, su.ch a small amount of flexibility could not possibly give the best riding. In passing, I might state that on the Guy two-ton vehicle, which is the equivalent of Messrs. Thornycroft's B.T. type, we have a deflection in the rear spring of over 4 ins, between the free .and loaded positions.

The Lubrication of Spring Leaves.

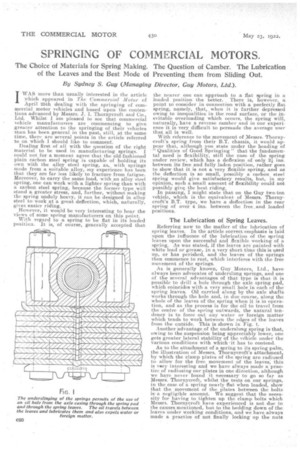

Referring now to the inafter of the lubrication of spring leaves. In the article correct emphasis is laid upon the influence of the lubrication of the spring leaves upon the successful and flexible working of a spring. As was stated, if the leaves are painted with white lead or grease, in a very short time this is used up, or has perished, and the leaves of the springs then commence to rust, which interferes with the free movement of the springs. As is generally known, Guy Motors,. Ltd., have always been advocates of tuiderslung springs, and one of the several advantages of that type is that it is possible to drill a hole through the axle spring pad, which coincides with a very small hole in each of the. spring leaves. Oil carried along by the axle shafts works through the hole and, in due course, along the whole of the leaves of the spring when it is in operation, and as the process is for the oil to travel from the centre of the. spring outwards, the natural tendency is to force out any water or foreign matter which tends to work between the edges of the leaves from the outSide. This is shown in Fig. 1. Another advantage of the underslung spring is that, owing to the suspension being appreciably lower, one gets greater lateral stability of the vdhicle under the various conditions with which 'it has to contend. As to the attachment of a spring to its spring palm, the illustration of Messrs. Thornycroft's attachment, by which the clamp plates of the spring are radiused to allow for the free movement of the leaves; this is very interesting and we have always made a-praotice of radiusing our plates in one direction, although we haye never found it necessary to go so far as Messrs. Thornyeroft, whilst the tests on our springs, in the ease. of a spring nearly flat when loaded, show that the movement of the plates between the bolts is a negligible amount. We suggest that the inec.essity for having to tighten up the clamp bolts which Messrs. Thornycroft have experienced is not due to the causes mentioned, but to the bedding down of the leaves under working conditions, and we have always made a practice of not finally locking up the nuts until after road-tests, by which time we find that the initial settling-down of the leal.'es has taken place and further adjustment is not required.

On the diagram showing the anchoring of the Thornyeroft spring (Fig. 6, illustrating the article in your issue of April th), we notice that a. bolt is shown going through the centre of the spring leaves.

Avoiding the Central Bolt Hole.

I would point out that the centre bolt necessitates a comparatively large hole being drilled through the centre of the spring, which immediately becomes a point of weakness, and, as a matter of interest, I would refer again to Fig. 1, which shows the type of anchorage which we have always used.

It. shows that the anchorplate is milled out to fit the spring pad on the axle. This plate has a radiused projection which registers with a depression of similar shape in the top leaf and continues through the spring in this manner, so that, when the anchor plates are bolted together, the whole becomes solid and, in the unlikely event of the clamp bolts becoming slack, the various registers prevent any possibility of the spring leaves sliding out. It will be seen that-the only hole through the leaves is the *-in. lubrication hole referred. to previously.

Shackles and their Lubrication.

Now, as to spring shackles, we have found another factor which influences the springing of the vehicle under certain conditions. more than -would a:,t first be realized, namely, the lubrication of the shackles. We have found that, when grease is used, in the course of time it solidifies mid becomes more or less a solid mass in the shackle pin or bush and not only ceases tofunction as a lubricant, but prevents the introduction of any fresh grease, with the result that the shackle pins very soon hind, causing excessive wear. Meantime, however, while this4iinding action is taking place, it appreciably interferes with the free movement of the springs. In our opinion, the only satisfactory way to lubricate any part is by oil, which should be introduced from the inside, to the bearing and so prevent the possibility of ingress of water or foreign matter. Fig. 2 illustrates our patented type -of shackle bolt for oil lubrication, which we find from -experience has obviated the aforementioned difficulties.

In the springing of commercial vehicles; particularly those utilize:d for passenger work, there are generally great opportunities for improvement, which not only would encourage still greater employment

of passenger vehicles, but would save wear and tear on the chassis, giving them a itery much longer useful life.