Contributions from Drivers and Mechanics.

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY for the Best Communication Received, and One Penny a Line of ten words for any thing else published.

Drivers of commercial-motor vehicles and tractors, and mechanics and foremen of garages or shops, are invited to send short contributions on any subject which is likely to prove of interest to our readers.. Work. shop tips and smart repairs ; long and successful runs ; interesting photographs: all are suitable subjects. Send a post-card, or a letter, or a sketch to us—no matter how short, or how written, or how worded. We will "knock it into shape" and prepare sketches, where necessary, before publication. The absence of a sketch does not disqualify for a prize. When writing use one side of the paper only and mention your employer's name as a guarantee of bona fides. Neither your own nor your employer's name will be disclosed. Payment will be made immediately after prsblication. Address your letters to The Editor, THE COMMERCIAL MOTOR, 7-15, Rosebery Avenue, London, E.C.

A Valve-spring Compression Device.

The sender of the following communication has been awarded the 10s. prize this week.

[851] "A.L." (Notting Hill) writes : —"During the 21. years that I have been a reader of the I do not think that I have seen a description, in the D. and M.' columns, of a useful tool for compressing the valve springs of an internal-combustion engine, of such a kind that the cotters could be readily withdrawn from the stems.

"I remember quite well having seen, knocking about the shops, from time to time, a number of dodges designed to carry out this purpose, and they

were invariably named by the men valve-lifters.' And a very good name too, for practically all that was done by any one of them, was to lift the valve, and then the trouble was even greater than ever, because the pressure of the spring on the cotter was not released. I have frequently used an arrangement that at. one and the same time holds down the valve and compresses the spring. I send you a sketch herewith [We have had this re-drawn.—End It will be seen that the upward movement of the hand-lever effects two purposes. If, when the lever has been pulled up, the pawl then be dropped into the rack, the device may be released and both the operator's hands are. free to work on the cotter. It is a good substantial tool and will stand a lot of knocking about in garage use.

"Might I remind your correspondent, 'E.B.' (Dartford), that the average mechanic who is used to small-workshop practice, would not go and waste a lot of time making special tools for odd jobs, when he could quite well find something -knocking about the shop that would serve his purpose. On the other hand, I have come across bushes which could not be extracted with anything that could be found in the scrap box ; even if that useful last resort happened to be as big as a bus. " Again there are bushes that can be cut out quite easily, and others that, owing to their hardness, it is impossible to treat in that way. As a test for E.B/s method of drawing bushes by means of a draw-bolt, etc., I will ask him to draw in this way the tappetguide bush from an ordinary crankcase, and to do that without taking the bottom half of the case down, and without removing the cylinders or the camshaft. It is when a man gets a puzzle like that, that it pays him very often to make a special little rig. It is all a question of time as a rule, as these special dodges do not cost a lot in material.

"I do not mind confessing that when I am in a fix over a special job of this sort I do not hesitate to run through my back numbers of the CAI.' You would, perhaps, be surprised to know how many times it has pulled inn out of trouble."

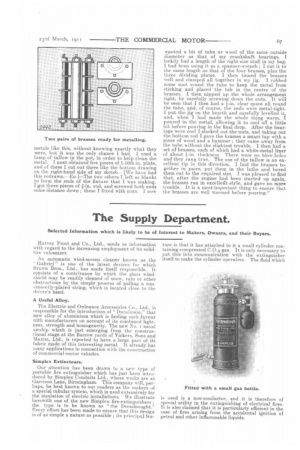

Metalling a Gang of Brasses.

r8521 " 11.11.8." (Luton) writes : —" Some while ago I was sent out on to the road to help an estate lorry which I was told was experiencing engine trouble. When I arrived there I found that the big ends had gone.' I did not want to send the brasses back to the shop, because, of course, this would have involved considerable delay. I looked round for a means of doing them myself somewhere on the spot. There was a small garage in the vicinity, where they had a small lathe and a brazing hearth and blowpipe. I got to work in this way. First of all I, of course, had to run out all the old metal from the brasses into an iron pot. That soon showed me that

should not have enough to make a new lining : but there was a set of scrap brasses in the garage, from which I got enough further white metal to serve my purpose. I knew it was not good practice to mix

metals like this, without knowing exactly what they were, hut it was the only chance I had. I used a lump of tallow in the pot, in order to help clean the metal. I next obtained five pieces of 1-16th-in. plate, and of these I cut out three like the bottom drawing on the right-hand side of my sketch..--[We have had this redrawn.—En.]—The two others I left as blanks to form the ends of the fixture that I was making. I got three pieces of i-in. rod, and screwed both ends some distance down ; these I fitted with nuts. I now wanted a bit of tube or wood of the same outside diameter as that of my crankshaft bearings. I luckily had a length of the right-size stuff in my bag. I had been using it as a spanner-wrench ; I cut it to the same length as that of the four brasses, plus the three dividing plates. I then tinned the brasses well and clamped all together in my jig. I rubbed some soot round the tube to keep the metal from sticking and placed the tub in the centre of the brasses. I then nipped up the whole arrangement tight, by carefully screwing down the nuts. It will be seen that. I then had a Fin, clear space all round the tube, and, of course, the ends were metal-tight.

put the jig on the hearth and carefully levelled it, and, when I had made the whole thing warm, I poured in the metal, allowing it to cool off a little hit before pouring in the final drop. After the bearings were cool I slacked out the nuts, and taking out the bottom rod I gave the brasses a smart tap with a piece of wood and a hammer ; they came away from the tube without the slightest trouble. I then had a set of brasses, each of which had a white-metal liner of about Fin, thickness. There were no blow-holes and they rang true. The use of the tallow is an excellent tip in this direction. I laid the brasses together in pairs, put them in the lathe and bored them out to the required size. I was pleased to find that, after the engine had been started up again, the brasses ran in excellerit style, and gave no more trouble. It is a most-important thing to ensure that the brasses are well warmed before pouring."