WORKSHOP REFRIGERATED SEMI-TRAILER

Page 130

If you've noticed an error in this article please click here to report it so we can fix it.

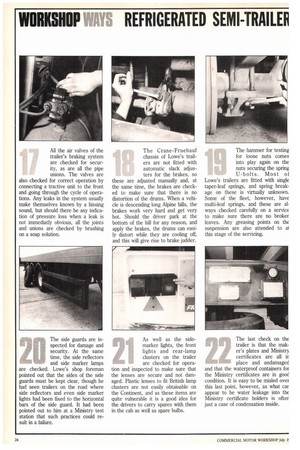

All the air valves of the trailer's braking system are checked for security, as are all the pipe unions. The valves are also checked for correct operation by connecting a tractive unit to the front and going through the cycle of operations. Any leaks in the system usually make themselves known by a hissing sound, but should there be any indication of pressure loss when a leak is not immediatly obvious, all the joints and unions are checked by brushing on a soap solution.

The side guards are inspected for damage and security. At the same time, the side reflectors and side marker lamps are checked. Lowe's shop foreman pointed out that the sides of the side guards must be kept clear, though he had seen trailers on the road where side reflectors and even side marker lights had been fixed to the horizontal bars of the side guard. It had been pointed out to him at a Ministry test station that such practices could result in a failure. The Crane-Fruehauf chassis of Lowe's trailers are not fitted with automatic slack adjusters for the brakes, so these are adjusted manually and, at the same time, the brakes are checked to make sure that there is no distortion of the drums. When a vehicle is descending long Alpine hills, the brakes work very hard and get very hot. Should the driver park at the bottom of the hill for any reason, and apply the brakes, the drums can easily distort while they are cooling off, and this will give rise to brake judder.

As well as the sidemarker fights, the front .' lights and rear-lamp tvt.. clusters on the trailer .9- ,'' are checked for operation and inspected to make sure that the lenses are secure and not damaged. Plastic lenses to fit British lamp clusters are not easily obtainable on the Continent, and as these items are quite vulnerable it is a good idea for the drivers to carry spares with them in the cab as well as spare bulbs. The hammer for testing for loose nuts comes into play again on the nuts securing the spring U-bolts. Most of Lowe's trailers are fitted with single taper-leaf springs, and spring breakage on these is virtually unknown. Some of the fleet, however, have multi-leaf springs, and these are always checked carefully on a service to make sure there are no broker leaves. Any greasing points on the suspension are also attended to al this stage of the servicing.

The last check on the trailer is that the maker's plates and Ministry certificates are all in place and undamaged and that the waterproof containers for the Ministry certificates are in good condition. It is easy to be misled over this last point, however, as what car appear to be water leakage into the Ministry certificate holders is after just a case of condensation inside.