road and workshop

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

by Handyman

Understanding metrics (2)

MECHANICS may feel inclined to question the wisdom of moving from the BSF and Whitworth threads they know so well to the new and perhaps strange metric system. However, there are a number of good reasons for going metric — the main one being that a mechanic's task will in due course be simplified.

For example, the British mechanic has during his career had to learn his way around something like 40 different sizes among the five Imperial threads in general use. The metric system will reduce this 40 to no more than seven between the diameters M6 and M 24. Also, there is only one ISO metric coarse thread instead of the five British threads.

The ISO metric thread is a derivative of the SI system (see"Metrics for mechanics (1)") and whilst the thread is somewhat finer than BSW it is not quite so fine as BSF. Many may argue that security must be improved when using the finer BSF thread with its finer helix giving a better grip. However, the fact is that the coarse metric thread is far stronger, will stand a heavier load and has less chance of corrosion or heat expansion. In addition, parts can be assembled more quickly and easily, and the old enemy of cross-threading is

practically eliminated.

Other factors in favour of the metric thread are production, distribution and storage, thus the task of the storekeeper will also be that much easier. Research carried out on the ISO metric coarse thread shows that there is no reason at all why it should not replace both Whitworth and BSF. Its tensile stress area is near both of the British threads, and there is more room to spare for plating with a protective coating. There is therefore less likelihood of seizure when taking a full load.

Identification marks Metric nuts and bolts will have their identification marked either on the bolt head or on the non-bearing face of the nut. The higher-grade bolt heads will have their grade stamped on them. The marking on the nut is in the form of a clock face — a single dot denotes 12 o'clock and the stamped-in bar will indicate the grade by its position in relation to the dot. Thus a nut which is grade 8.8 will have a bar in the 8 o'clock position.

Many industries are now well ahead with metric programmes and already conversion -tables and charts are available, covering a wide range of products. I would advise mechanics to get in touch with their local suppliers of nuts and bolts for comparison charts. If these are not yet available locally then I am sure they will get ready assistance by writing to the following company: G.K.N. Bolts and Nuts Ltd, Marketing and Distribution Division, PO Box 12, Darlaston, S. Staffs.

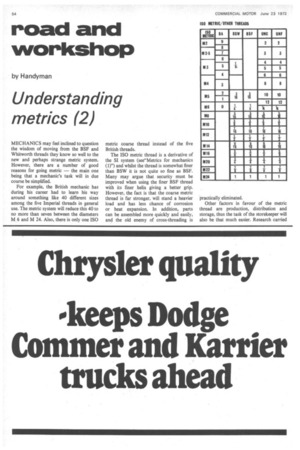

My chart shows comparisons between the main threads in use at the moment and the ISO metrio M' numbers.