I.A.E. Proves Corrosion to be The Cause of Cylinder Wear

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

Condensation of Products of Combustion Caused by Cold Cylinder Walls the Main Factor

A REPORT lately issued by the Research and Standardization Committee of the Institution of Automobile Engineers, formed with the co-operation of the Department of 'Scientific and Industrial Research, describes a recent achievement in tracing the cause of cylinder wear, which is likely to have a big influent* on the future of internal

combustion-engine design and to contribute greatly towards the elimination of this heavy item of maintenance expenditure.

It has been established that cold cylinder walls, causing condensation of the products of combustion, with consequent corrosion constitute a basic cause of cylinder wear. In a series of careful experiments made during the past lg months, in the course of which the numerous variables weed placed under judicious control, the many—and often cow flicting—theories put forward to explain cylinder wear, Flitch ps inadequate lubrication or dilution Of oil on the cylinder walls, have been investigated and exploded.

For example, it has been found that cylinder wear was not accelerated by the dilution of the lubricant with petrol even up to 90 per cent., except when the oil was contaminated with abrasive -matter. It has been shown that a deficiency of •oil was not an important factor, even when the cylinder-wall temperatures reached so high a figure as 205 degrees C. Cylinder wear was not accelerated even when the quantity of oil supplied was reduced in the ratio teC 100 to 1.

Provided that the engines on which the tests were carried out were warmed up sufficiently rapidly, a series of stopping and starting tests produced evidence to show that delayed lubrication and strangling of the carburetter contri B42

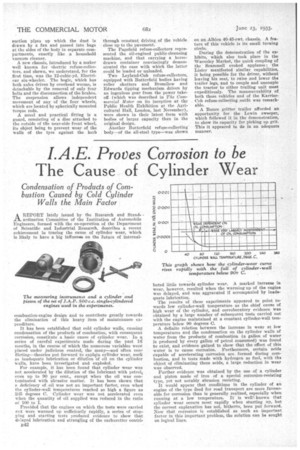

buted little towards cylinder wear. A marked increase in wear, however, resulted when the warming up of the engine was delayed, and was aggravated if accompanied by inadequate lubrication.

The results of these experiments appeared to point towards low cylinder-wall temperature as the chief cause of high wear of the cylinder, and corroboratory evidence was obtained by a large number of subsequent tests carried out with the engine maintained at a constant cylinder-wall temperature below 90 degrees C. A definite relation between the increase in wear at low temperatures and the condensation on the cylinder walls of water from the products of combustion (a gallon of water is produced by every gallon of petrol consumed) was found to exist, and evidence gained to show that the effect of this water is to cause corrosion. Furthermore, certain acids capable of accelerating corrosion are formed during combustion, and in tests made with hydrogen as fuel, with the object of eliminating these acids, a large reduction in wear was observed.

Further evidence was obtained by the use of a cylinder and piston made of iron of a special corrosion-resisting type, yet not notably abrasion resisting.

It would appear that conditions in the cylinder of an engine of the type Ased for road transport are more favourable for corrosion than is generally realized, especially when running at a low temperature. It' is went known that cylinder wear occurs most rapidly when starting up, but the correct explanation has not, hitherto, been put forward. Now that corrosion is established as such an important factor in this important problem, the solution can be sought on logical lines.