AN IMPROVED VACUUM GULLY EMPTIER.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

Details of a New and Interesting Yorkshire Machine which Embodies Many Features Making for Efficiency and Speed.

irANY READERS of this journal IY.Lare familiar with the patented principle employed in the system of gully emptying utilized by the Yorkshire Patent Steam Wagon Co., of nunslet, Leeds. The principle involves the use of a sludge compartment and a separate vacuum tank, this tank being of much smaller capacity than the sludge compartment. A working vacuum can be obtained in 25 seconds, whereas a much longer period is required in machines in which the vacuum is formed in the same portion of the vehicle as contains the sludge. Other advantages of the system are that the sludge tank can be lightly constructed, as it is not necessary to build It to withstand the crashing pressure of the ttmosphere ; also, excess water can be run off and used for re-sealing the gullies if required. This is a considerable advantage, as a much bigger "paying load" of solid matter can be carried per trip, for, if the water could not be utilized in the manner stated, it would all have to be carried along with the solid matter and discharged with it at the tip.

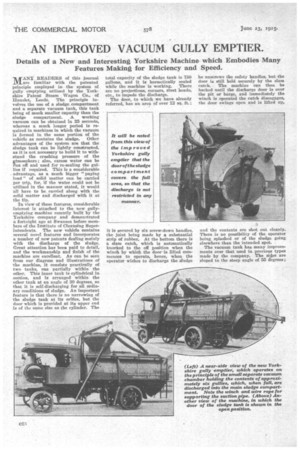

In view of these features, considerable interest is attached to the new gullyemptying machine recently built by the Yorkshire company and demonetrated a fortnight ago at Swansea before members of the Institute of Cleansing Superintendents. The new vehicle contains several novel features and incorporates a number of new patents dealing mainly with the discharge of the sludge. Great attention has been paid to detail, and the workmanship and finish of the machine are excellent. As can be seen from our diagram and illustrations of the machine, it consists practically of two tanks, one partially within the other. This inner tank is cylindrical in section, and is arranged within the other tank at an angle of 30 degrees, so that it is self-discharging for all ordinary conditions of sludge. An important feature is that there is no narrowing of the sludge tank at its orifice, but the door which is provided at its upper end is of the same size as the cylinder. The total capacity of the sludge tank is 750 gallons, and it is hermetically sealed while the machine is working. There are no projections, corners, rivet heads, etc., to impede the discharge.

The door, to which we have already referred, has an area of over 12 sq. ft.;

it is secured by six screw-down handles, the joint being made by a substantial strip of rubber. At the bottom there is a slam catch, which is automatically knocked to the off position when the winch by which the door is lifted commences to operate, hence, when the operator wishes to discharge the sludge

he unscrews the safety handles, but the door is still held securely by the slam catch. The machine can then be hacked until the discharge door is over the pit or barge, and immediately the winch is operated the catch disengages, the door swings open and is lifted up,

and the contents are shot out cleanly. There is no possibility of the operator being splashed or of the sludge going elsewhere than the intended spot.

The vacuum tank has many improvements over that used in previous types made by the company. The sides are sloped to the steep angle of 55 degrees;

It has a quick-opening cover for inspection and a much larger opening at the bottom. It is fastened to the top of the sludge compartment, and as the joint is Perfectly watertight there is no chance

for the sludge to overflow. An improved type of door is fitted at the underside of the vacuum chamber, and this will work practically indefinitely without attention. The suction pipe is of light steel with a convenient doublehandle and .a quick-opening valve. It is connected to the vacuum tank by flexible pipes and wrought-iron bends, and as such articles as crowbars, umbrellas, coils of wire and other unexpected things are occasionally found in the gullies, quick-opening inspection covers are provided, where needed, at the corners. The weight of the pipe is taken by a wire rope carried by pulleys over a swinging jib.

A D-section water tank of 900 gallons capacity surrounds the sludge tank and is internally coated with bitumen paint. The boiler is fed from this tank, and the arrangement is such that there is a residue of 50 gallons after all the resealing valves, sprinklers and washing gear have ceased operating.

The sludge sometimes contains relarge percentage of sand and, as is well known, this prevents the sludge from sliding out,no matter at what angle, within reason, it is inclined. The tanks have been made in the past to blow out the sand by pressure, but even this is not satisfactory when once an air space has been made, and so far hand-shovelling has been the only effective method of getting rid of matter. In the new Yorkshire machine a powerful jet of water is forced by steam pressure to the underside of the sludge, thus washing it away from underneath, as once this part of the sludge begins to move the whole mass moves slowly by its own weight. Digging out is thus entirely obviated.

The whole machine is of steel construction,with the exception of a wooden footboard provided along the top for inspection purposes. hykactually looks smaller than previous Models, but is capable of doing more work. In our illustrations of the apparatus we show it fitted to the well-known shaftdriven Yorkshire chassis, but it can be just as easily fitted to their chain-driven model. We understand there is at present a brisk demand for the previous types of gully emptier made by the company, but they have decided to introduce this new model in order that municipalities may have the immediate benefit of the improvements. The whole machine has been thoroughly thought out and tested over a considerable period. It is not one produced in haste to be repented of at leisure.

For the operation of the machine only two men are required—the driver and the operator. Sometimes a third man is employed to go in advance to open the gully grates, so there is no time wasted by tha machine while sticking grates are being forced open.

The operator slides the suction pipe into the gully, opens the quick-acting valves, and the sludge is immediately forced up into the vacuum tank by atmospheric pressure. The suction pipe is counterbalanced by weights and can be slung about quite easily. The vacuum tank holds the contents of six average gullies, and a float and valve obviate an overflow of the sludge.