Weight saved in Eaton axle changes

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

• Revised designs of Eaton driving heads and complete axles are now being fitted by Chrysler UK, Ford, British Leyland at Bathgate, and ERF. Vauxhall is scheduled to begin offering the new pattern in August. The new axles are about 701b lighter than their predecessors.

Known as the "interim" axle, the layout owes much to the 70 series units first seen at Earls Court in 1968. Resistance from vehicle manufacturers has compelled Eaton to shelve its square-section casing, however, and the round arm case is continued in a lightened form.

Along with the engineering changes Eaton has changed its designations; the most widely used two-speed axle in Britain, the 18802 unit, is discontinued in favour of two new models. For gear ratios up to 5.57, the driving head is unchanged dimensionally and is known as the 18200; the 6.14, 6.5, and 7.17 ratio models--designated 18220—now feature crown-wheel ring gear teeth increased in width from 2ir to 2fin., so that the pitch diameter goes up from 16 to 16-fin. On the lighter 16 series axles the ring gear diameter has been raised from 144to 15in.

Eaton engineers say the wider crown-wheel and mating pinion teeth were adopted to meet a requirement for greater durability, especially on site work. It has not been necessary to increase the price for the heavy duty gearing. In fact, the design changes are accompanied by a reduction in cost to the manufacturer.

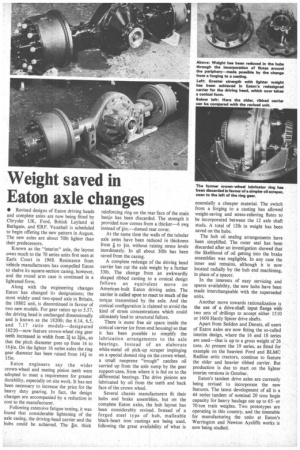

Following extensive fatigue testing, it was found that considerable lightening of the axle casing, the driving-head carrier and the hubs could be achieved. The aim thick reinforcing ring on the rear face of the main banjo has been discarded. The strength it provided now comes from a thicker-6 swg instead of iin.--domed rear cover.

At the same time the walls of the tubular axle arms have been reduced in thickness from to fin. without raising stress levels inordinately. In all about 301b has been saved from the casing.

A complete redesign of the driving head carrier has cut the axle weight by a further 331b. The change from an awkwardly shaped ribbed casting to a conical design follows an equivalent move on American-built Eaton driving axles. The carrier is called upon to react to much of the torque transmitted by the axle. And the conical configuration is claimed to avoid the kind of stress concentrations which could ultimately lead to structural failure.

There is more free air space inside the conical carrier (or front-end housing) so that it has been possible to simplify the lubrication arrangements to the axle bearings. Instead of an elaborate white-metal oil pick-up scraper impinging on a special domed ring on the crown wheel, a small neoprene "trough" catches oil carried up from the axle sump by the gear support-case, from where it is fed on to the differential bearings. The drive pinions are lubricated by oil from the teeth and back face of the crown wheel.

Several chassis manufacturers fit their hubs and brake assemblies, but on the complete Eaton axles, the hub layout has been considerably revised. Instead of a forged steel type of hub, malleable black-heart iron castings are being used, following the great availability of what is essentially a cheaper material. The switch from a forging to a casting has allowed weight-saving and stress-relieving flutes to be incorporated between the 12 axle shaft studs. A total of 131b in weight has been saved on the hubs.

The hub oil sealing arrangements have been simplified. The outer seal has been discarded after an investigation showed that the likelihood of oil getting into the brake assemblies was negligible. In any case the inner seal remains, although it is now located radially by the hub end machining, in place of a spacer.

In the interests of easy servicing and spares availability, the new hubs have been made interchangeable with the superseded units.

Another move towards rationalization is the use of a drive-shaft input flange with two sets of drillings to accept either 1510 or 1600 Hardy Spicer drive shafts.

Apart from Seddon and Dennis, all users of Eaton axles are now fitting the so-called interim design, where the 16 and 18 series are used—that is up to a gross weight of 26 tons. At present the 19 series, as fitted for example on the 'heaviest Ford and BLMC Redline attic tractors, continue to feature the older and heavier ribbed carrier. But production is due to start on the lighter interim versions in October.

Eaton's tandem drive axles are currently being revised to incorporate the new features. The latest development of all is a 44 series tandem of nominal 20 tons bogie capacity for heavy haulage use up to 65or 70-ton train weights. Two prototypes are operating in this country, and the timetable for manufacturing the units at Eaton's Warrington and Newton Aycliffe works is now being studied.