Gives an ARAB its Head

Page 34

Page 35

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

High All-round Performance from Chassis Designed on Sound Engineering Principles and Character ized by Clean Layout

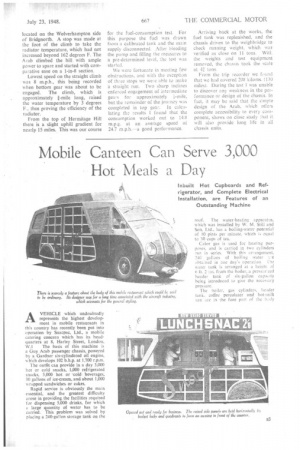

0 travel with safety at high

speed in narrow country lanes on a left-hand-steered 8-ft. wide chassis requires that the driver "should have full confidence in the performance of the vehicle. I gained this confidence in the Guy Arab within a few minutes of taking the wheel. It was lively in response to the accelerator, smooth and efficient in braking when occasion demanded, and accurate in steering.

The Arab was well under control at all speeds. Keeping to the correct side of the road, I took normal road bends at speeds in excess of 40 m.p.h. without protest from the tyres.

Although the test chassis was fitted with a Gardner six-cylindered oil engine, it is offered with the alternative five-cylindered unit. The power unit is retained in the chassis at two points at the front and one point at the rear. Springs are fitted in the front suspension units to absorb high-frequency oscillations, whilst the rear unit comprises a halfcircle of . oil-resisting rubber, of homogeneous hardness to provide maximum resilience.

The open design of .the single-plate clutch unit helps to keep the unit at an even temperature and facilitates adjustment and remZiVai. Large ventilating holes are drilled in the periphery of the flywheel to assist in cooling and increase the working

A32 life of the clutch. A cast-iron wearing plate is attached to the flywheel.

All four forward gears are in constant mesh and engaged by sliding dogs. The gearbox, offset in the frame, is independently mounted amidships in the chassis. It is slung from the frame through resilient rubber cushions, which also assist in the alignment of the transmission.

Gearbox Easily Dismantled

With the gearbox in this position, and the accessibility offered by the top cover, the entire unit may, if necessary, be dismantled in the chassis. Single-pieee propeller shafts equipped with Layrub universal couplings carry the transmission between clutch, gearbox and rear axle.

Like the gearbox, the worm housing is offset, an underslung worm being employed. With the many stops to the mile encountered in bus work, worm-driven axles have a tendency towards high lubricatingoil temperatures. The large-capacity worm casing of the Arab chassis assists in keeping the lubricant at a reasonable temperature.

Typically Arab in design, the axle, worm and differential gear embody no superfluous weight, yet they are notably strong in construction. The worm shaft is carried by a double taper-roller bearing at the rear and a roller hearing at the front Taperroller bearings are also used for the worm wheel, which houses the heavy-duty differential gear. The model tested was equipped with an axle ratio of 4.8 to I. The standard ratio for home models is 5.6 to 1, with 6.25 to 1 as an alternative.

Clayton Dewandre compressedair braking was employed on the chassis tested. This is alternative to the vacuum system and is available for home and overseas models. Secured to a frame cross-member, the reciprocating compressor unit is shaft-driven from the forward end of the gearbox. Air is supplied through a conventional duplex Tank to a control valve linked to the brake pedal. A diverter valve is fitted between the main and auxiliary pressure tanks, and an unloader valve controls the

system at 75-110 lb. per sq. in. Chassis stability is assured by a combination of large semi-elliptic

springs, an anti-roll device and Luvax shock absorbers which are fitted as standard on all models. The excellent cornering characteristics noticed on the chassis may have been assisted by the 8-ft. width of the model.

The well proportioned chassis frame is of nickel-steel channel section, braced by four channelsection and two tubular cross-members, all of which are bolted in position. Substantial flitch plates are fitted to the front portion of the

frame and to the downswept platform section at the rear.

A grouped nipple lubrication system is employed, all the nipples being enclosed in boxes to exclude mud and water. The lubrication pipes are connected to the front and rear shackles through flexible hoses.

109-mile Route

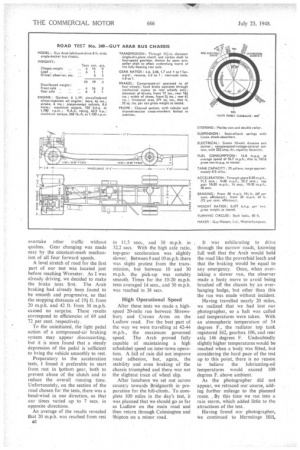

Except for the left-hand steering and the offset transmission units, the test chassis was similar to the home models. The high axle ratio suggested that the vehicle would be used for long-distance inter-town services, so a 100-mile route was planned over a course which might be representative of these conditions.

Leaving Wolverhampton, we made our way towards Shifnal and Wellington. At first we encountered light traffic, and overtaking slowermoving vehicles was not an easy task, having regard to the position of the driver and the width of the chassis. Once clear of traffic, we settled down to a fast but steady pace.

With a cross wind approaching

gale force, our speed appeared to be much greater than 65 k.p.h. (40 mph.), shown on the speedometer. Not wishing to risk damage to the vehicle, I waited until we had passed

through the narrow thoroughfares of

Wellington before .relegating the works driver to the observer's seat.

At first 1. found difficulty in judging the position of the off-side wheels, because from the driving scat the chassis had the appearance of being more than half the road in width. Within a few minutes the stability of the chassis and the accuracy of the steering had given roe confidence to overtake other traffic without qualms. Gear changing was made easy by the constant-mesh mechanism of all four forward speeds.

A level stretch of road for the first part of our test was located just before reaching Wroxeter. As I was already driving, we decided to make the brake tests first. The Arab braking had already been found to be smooth and progressive, so that the stopping distances of 19i ft. from 20 m.p.h. and 42 ft. from 30 m.p.h. caused no surprise. These results correspond to efficiencies of 69 and 72 per cent. respectively.

To the uninitiated, the light pedal action of a compressed-air braking system may appear disconcerting, but it is soon found that a steady depression of the pedal is sufficient to bring the vehicle smoothly to rest.

Preparatory to the acceleration tests, I found it preferable to start from rest in bottom gear, both to prevent abuse of the clutch and to reduce the overall running time. Unfortunately, on the section of the road chosen for the tests, there was a head-wind in one direction, so that our times varied up to 7 secs. in opposite directions.

An average of the results revealed that 20 m.p.h. was reached from rest B2

in 11.5 secs., and 30 m.p.h. in 32.2 secs. With the high axle ratio, top-gear acceleration was slightly slower. Between 8 and 10 m.p.h. there was slight protest from the transmission, but between 10 and 30 m.p.h. the pick-up was notably smooth. Times for the 10-20 m.p.h. tests averaged 14 secs., and 30 m.p.h. was reached in 38 secs.

High Operational Speed

After these tests we made a highspeed 20-mile run between Shrewsbury and Craven Arms on the Ludlow road. For the best part of the way we were travelling at 42-44 m.p.h., the maximum governed speed. The Arab proved fully capable of maintaining a high scheduled speed on inter-town operation. A fall of rain did not improve road adhesion, but, again, the stability and even braking of the chassis triumphed and there was not the slightest trace of wheel slip.

After luncheon we set out across country towards Bridgnorth in preparation for the hill-climb,, To complete 100 miles in the day's test, it was planned that we should go as far as Ludlow on the main road and then return through Culmington and Shipton on a minor road.

It was exhilarating to drive through the narrow roads, knowing full well that the Arab would hold the road like the proverbial leech and that the braking would be equal to any emergency. Once, when overtaking a slower van, the observer made a hasty move to avoid being brushed off the chassis by an overhanging hedge, but other than this the run was made without incident.

Having travelled nearly 20 miles, we realized that we had lost our photographer, so a halt was called and temperatures were taken. With an atmospheric temperature of 54 degrees F., the radiator tap tank registered 162, gearbox 106, and rear axle 146 degrees F. Undoubtedly slightly higher temperatures would be reached when a body was fitted, but considering the hard pace of the test up to this point, there is no reason to believe the lubricating-oil temperatures would exceed 100 degrees F. above ambient.

As the photographer did not appear, we retraced our course, adding further mileage to the planned route. , By this time we ran into a rain storm, which added little to the attractions of the test.

Having found our photographer, we continued to Hermitage Hill,

located em the Wolverhampton side of Bridgnorth. A stop was made at the foot of the climb to take the radiator temperature, which had not increased beyond 162 degrees F. The Arab climbed the hill with ample power to spare and started with comparative ease on a 1-in-3 section.

Lowest speed on the straight climb was 8 m.p.h., this being recorded when bottom gear was about to be engaged. The climb, which is approximately f-mile long, raised the water temperature by 3 degrees F., thus proving the efficiency of the radiator.

From the top of Hermitage Hill there is a slight uphill gradient for nearly 15 miles.. This was our course for the fuel-consumption test. For this purpose the fuel was drawn from a calibrated tank and the main supply disconnected. After bleeding the pump and filling the measures to a pre-determined level, the test was started.

We were fortunate in meeting few obstructions, and with the exception of three stops wc were able to make a straight run. Two sharp inclines enforced engagement of intermediate gears for approximately

but the remainder of the journey was

completed in top gear. In calculating the results I found that the consumption worked out to 14.8 m.p.g. at an average speed of 24.7 mph.—a good performance. Arriving back at the works, the fuel tank was replenished, and the chassis driven to the weighbridge to check running weight, which was verified as close on 11 tons. Witl, the weights and test equipment removed, the chassis took the scale at 4 tons.

From the trip recorder we found that we had covered 208 kiloms. (130 miles). During the test I was unable to discover any weakness in the performance or design of the chassis. In fact, it may be said that the simple design of the Arab, which oilers complete accessibility to every component, shows on close study that it will also provide long life in all chassis units.