Efficient Operation on Gas

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

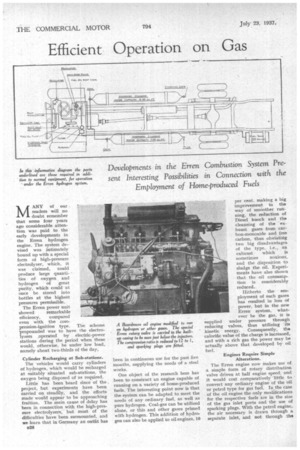

Developments in the Erren Combustion System Present interesting Possibilities in Connection with the Employment of Home-produced Fuels MANY of our readers will no doubt remember that some four years ago considerable attention was paid to the early developments in the Erren hydrogen engine. The system devised was intimately bound up with a special form of high-pressure electrolyzer, which, it was claimed, could produce large quantities of oxygen and hydrogen of great purity, which could at once be stored into bottles at the highest pressures permissible.

The Erren power unit showed remarkable efficiency, compared even with the compression-ignition type. The scheme propounded was to have the electrolyzers operated by electric-power stations during the period when these would, otherwise, be under low load, namely about two-thirds of the day.

Cylinder Recharging at Sub-stations.

The vehicles would carry cylinders of hydrogen, which would be recharged at suitably situated sub-stations, the oxygen being disposed of as required.

Little has been heard since of the project, but experiments have been carried on steadily, and the efforts made would appear to be approaching fruition. The main cause of delay has been in connection with the high-pressure electrolyzers, but most of the difficulties have been surmounted, and we learn that in Germany an outfit has

1326 been in continuous use for the past live months, supplying the needs of a steel works.

One object of the research here has been to construct an engine capable of running on a variety of home-produced fuels. The interesting point now is that the system can be adapted to meet the needs of any ordinary fuel, as well as pure hydrogen. Coal-gas can be utilized alone, or this and other gases primed with hydrogen. This addition of hydro. gnu can also be applied to oil engines, 10

per cent, making a big improvement in the way of smoother run

ning, the reduction of Diesel knock and the cleansing of the exhaust gases from carhon-monoxide and free carbon, thus obviating two big disadvantages of the type, i.e., Ap. exhaust which is

sometimes noxious, and the disposition to sludge the oil. Experiments have also shown that the oil consumption is considerably reduced.

Hitherto the em ployment of such gases has resulted in loss of power, but in the new Erren system, whatever be the gas, it is supplied under pressure through reducing valves, thus utilizing its kinetic energy. Consequently, the calorific value of the charge is increased, and with a rich gas the power may be actually above that developed by oil fuel.

Engines Require Simple Alterations.

The Erren engine now Makes use of a simple form of rotary distribution valve driven at half engine speed, and it would cost comparatively 'little to convert any ordinary engine of the oil or petrol type for gas fuel. In the case of the oil engine the only modifications for the respective fuels are in the size of the gas inlet ports and the use of sparking plugs. With the petrol engine, the' air necessary is drawn through a separate inlet, and not through the

carburetter. The injection pressure is about 60 lb. for coal-gas and 90 lb. for hydrogen. Where the oil engine is concerned, the change-over from oil fuel to hydrogen, or to any percentage dilution by this gas, can be made in a moment.

Figures submitted by the Erren Engineering Co., Ltd., Abbey House. Victoria Street, London, S.W.1, show that, during tests, a vehicle which normally ran 11.60 m.p.g. on Dieselene gave the following results : coal-gas, .66 cubic metre per mile; hydrogen, .84 cubic metre per mile.

This means that 7.7 cubic metres of coal-gas or 9.75 cubic metres of hydrogen are equivalent to one gallon of Dieselene. Other results show that 6.2 cubic metres of hydrogen or 5.9 cubic metres of coal-gas equal one gallon of petrol, the consumption practically corresponding to the heat values of the fuels used.

A normal oil engine gives an average brake thermal efficiency. of about 34 per cent.; apetrol engine, 22-23 per cent.; whilst the hydrogen engine is claimed to

give 42 per cent. These figures were obtained on an A.E.C. six-cylindered oil engine which had been converted. A petrol engine converted to hydrogen gave an efficiency of 32 per cent.

Exhaust-gas analysis of an engine using hydrogen showed CO, 0 per cent.; CO„, 0 per cent.; 02, 13.4 per cent. While operating on oil the results were CO, 1.6 per cent.; CO.,, 5 per cent.; 0,, 4.4 per cent.

Use of " Off-Peak z' Gas.

It is suggested that with coae-ga‘, as with electricity, the off-peak production load could be taken advantage of for filling gas cylinders, thus releasing oil and petrol mainly for the use of the fighting services.

For every ton of imported petrol supplanted by hydrogen, six tons of coal would be used, and oxygen would be produced as a valuable by-product in the ratio of one of oxygen to two of hydrogen. It is believed that two buses running on hydrogen would mean the employment of one miner.

London's buses use 118,000 tons of petrol and 34,000 tons of oil fuel per year, whilst the carbon dioxide and carbon monoxide discharged from the exhausts comprise many hundreds of tons per day. If these could be converted to a system which would give a clean exhaust and, at the same time, utilize home-produced fuel, the advantages would be considerable.

New Light Gas Cylinders.

An interesting point is that Germany is now producing high-pressure gas cylinders one-third of the weight of our equivalent cylinders made from hightensile, steel. They are of thin steel wound with piano wire, with an over-, winding of light-alloy wire.

At a demonstration held last week we saw a small National single-cylindered engine, which, when operated on hydrogen, could run at as low a speed as 135 r.p.m., just sufficient to get over compression, whilst a larger single cylindered, two-stroke unit aetually operated with perfect regularity at 'between 34 and 35 r.p.m. We had a run of some miles on a Leyland bus equipped with a Beardmore oil engine converted to the Erren system. There were no alterations to normal design except that special injection apparatus had been inserted in the cylinder walls, and sparking plugs had been put into the heads. This simple arrangement permits the engine to run on oil fuel, hydrogen, or oil assisted by hydrogen. We noted that the engine ran distinctly better with pure hydrogen or with hydrogen priming than on oil fuel alone. Coal gas was also tested. The addition of hydrogen gives considerably higher starting torque, more complete combustion and a saving of seine 32 per cent, in the oil fuel used, whilst the power output is increased by about 20 per cent. As an oil engine, the normal compression was 15 to 1; for hydrogen the ratio was lowered to 12 to 1.

Costs are, of course, of considerable importance. Purely on the fuel basis, 350 cubic ft. of hydrogen or 270 cubic ft. of coal-gas equal a gallon of Diesel oil, but taking upkeep and maintenance into account, the corresponding equivalents would be 320 cubic ft. and 250 cubic ft.

It is said that hydrogen can be produced at 3s. 2d.

per 1,000 cubic ft., using "off-peak" electric current at 0.2d. per unit. This means -that hydrogen at this price could do the same work as Diesel oil at is. Oeel. per gallon; or as petrol at W. per gallon.

This is without crediting the hydrogen with any rebate from the oxygen, which it is thought could be sold at 2s. 6d. per 1,000 cubic ft. (to-day the commercial price is 15s, per 1,000 cubic ft.). This would bring the cost of hydrogen to 8d., equivalent to Diesel oil at 3.1d. per gallon and petrol at 2d. per gallon.

The company own § the world rights, with the exception of Germany, of the Even engine, and has arrangements and agreements covering the sale and manufacture of all known makes of high-pressure electrolyzer.

-The Weight of Gas Cylinders.

When considering the employment of compressed gas on a vehicle due attention must be given to such items as the increase of weight. It is, for example, estimated that the weight of hydrogen in bottles would constitute approximately 8 per cent, of the unladen weight. For an average vehicle, two cylinders eontaining a total of 85 cubic ft. are stated to give a range of approximately 85 miles. A cylinder of a capacity sufficient for hydrogen priming could, however, be quite light.