GOING TO

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

BLAZES

For a long time Dennis had the front line fire-appliance market all its own way. Now there are a number o stron• competitors from overseas, and a new British contender — the Reynolds Boughton Bri•adier.

• The aircraft crashes at Lockerbie and on the M1 are stark reminders that fire brigades must have the equipment to ensure a rapid response to all sorts of emergency. Last year Britain's fire fighters attended 387,000 major incidents (not counting false alarms, cats in trees or children with heads jammed in railings).

When help arrives it is usually in the form of the ubiquitous B-type fire tender with its crew of six. There are about 3,500 of these front line appliances in Britain, 3,000 of them in England and Wales. Designs vary according to local brigade tastes — but they all have to meet the performance criteria laid down by the Home Office in its JCDD (Joint Committee for Design and Development) 1/3 regulations.

Dennis of Guildford has been building fire engines since the turn of the century — indeed it is synonymous with them — but more recently the likes of Volvo and Scania have been moving into the vacuum left by the demise of Bedford.

Now, following a three-year development programme, another British specialist vehicle builder, Reynolds Boughton (Devon) — perhaps better known for its multi-wheel-drive airfield crash tenders — is set to enter the fray with an innovative B-type appliance, the Brigadier.

So far only a prototype has been produced, but following a lengthy in-service evaluation by the Devon Fire and Rescue Service, and a tour of another 25 brigades, it has come our way.

Many brigades have settled for conventional bread-and-butter truck chassis as a base for their equipment, but RB has designed its own vehicle from the ground up, with handling and crew environment uppermost in its mind.

II CAB COMFORT

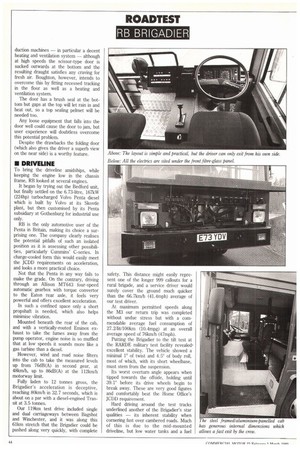

Visually the mid-engined Brigadier's most striking feature is its 2.45m-wide, steelframed, non-tilting crewcab. It has a low, squat look to it, but its generous internal dimensions will accommodate four firemen on the rear bench against padded frames that hold clip-in breathing apparatus (BAs). Three spare BA cylinders mount between them.

In the rear there is 1.56m of headroom with plenty of knee space for crewmembers of average height and padded safety rails ahead of them.

Large, opening side windows provide the crew with good clear lateral views; the offside window doubles as an emergency exit which Boughton intends to enlarge on production models as an added safety measure. On arrival at an incident the crew will exit via a 520mm gap between the commander's seat and the B-post, into the footwell and out through the folding side door which is operated by either front or rear-seated crew-members.

The folding door hinges inwards to the A-post, exposing a 9 70mm-wide, 1,670mm-high opening.

If the 570mm bottom step was closer to the ground a running exit would be less spine jarring, but lowering it would compromise the vehicle's 16.5° front approach angle, so any change would have to be an agreed compromise.

Getting behind the wheel quickly presents few problems for the driver thanks to the wide, fully opening door. Button ignition beats fiddling with a bunch of keys and the stirrup-type park brake control, adjustable steering wheel and light indicator are all a la Roadrunner and are simple to use.

The emergency alarm, lights and pump switches are positioned in the centre of the instrument panel in easy reach of the commander and driver. Above them in the header rail are the door release buttons, pre-heater switch, gauges and Bendix CRM anti-lock braking system checklight.

For this prototype RB has omitted refinements which will be standard in pro duction machines — in particular a decent heating and ventilation system — although at high speeds the scissor-type door is sucked outwards at the bottom and the resulting draught satisfies any craving for fresh air. Boughton, however, intends to overcome this by fitting recessed tracking in the floor as well as a heating and ventilation system.

The door has a brush seal at the bottom but gaps at the top will let rain in and heat out, so a top sealing pelmet will be needed too.

Any loose equipment that falls into the door well could cause the door to jam, but user experience will doubtless overcome this potential problem.

Despite the drawbacks the folding door (which also gives the driver a superb view on the near side) is a worthy feature.

• DRIVELI NE

To bring the driveline amidships, while keeping the engine low in the chassis frame, RB looked at several engines.

It began by trying out the Bedford unit, but finally settled on the 6.73-litre, 167kW (224hp) turbocharged Volvo Penta diesel which is built by Volvo at its Skovde plant, but then customised by its Penta subsidiary at Gothenburg for industrial use only.

RB is the only automotive user of the Penta in Britain, making its choice a surprising one. The company dearly realises the potential pitfalls of such an isolated position as it is assessing other possibilities, particularly Cummins' C-series. In charge-cooled form this would easily meet the JCDD requirements on acceleration, and looks a more practical choice.

Not that the Penta in any way fails to make the grade. On the contrary, driving through an Allison MT643 four-speed automatic gearbox with torque convertor to the Eaton rear axle, it feels very powerful and offers excellent acceleration.

In such a confined space only a short propshaft is needed, which also helps minimise vibration.

Mounted beneath the rear of the cab, and with a vertically-routed Eminox exhaust to take the fumes away from the pump operator, engine noise is so muffled that at low speeds it sounds more like a gas turbine than a diesel.

However, wind and road noise filters into the cab to take the measured levels up from 76dB(A) in second gear, at 413km/h, up to 86dB(A) at the 112km/h motorway limit.

Fully laden to 12 tonnes gross, the Brigadier's acceleration is deceptive, reaching 80km/h in 32.7 seconds, which is about on a par with a diesel-engined Transit at 3.5 tonnes.

Our 1191cm test drive included single and dual carriageways between Bagshot and Winchester, and it was along this 61km stretch that the Brigadier could be pushed along very quickly, with complete safety. This distance might easily represent one of the longer 999 callouts for a rural brigade, and a 'service driver would surely cover the ground much quicker than the 66.71cm/h (41.4mph) average of our test driver.

At maximum permitted speeds along the M3 our return trip was completed without undue stress but with a commendable average fuel consumption of 27.2/lit/100km (10.4mpg) at an overall average speed of 76km/h (47mph).

Putting the Brigadier to the tilt test at the RARDE military test facility revealed, excellent stability. The vehicle showed a minimal 1° of twist and 4.5° of body roll, most of which, with its short wheelbase, must stem from the suspension.

Its worst overturn angle appears when tipped towards the offside, holding until 39.10 before its drive wheels begin to break away. These are very good figures and comfortably beat the Home Office's JCDD requirement.

Hard driving around the test tracks underlined another of the Brigadier's star qualities — its inherent stability when cornering fast over cambered roads. Much of this is due to the mid-mounted driveline, but low water tanks and a fuel tank that straddles the frame behind the rear axle must also help, as did the test weights in the bottom of the lockers.

High speed handling is good: its bulky leafspring packs give a firm ride but do look unecessarily hefty.

Despite several attempts, RB's appliance failed to restart on the 33% (1-in3) test hill, but it mounted the 25% (1-in-4) slope smoothly, if slowly. The park brake handled both slopes, facing up and down, complementing the positive feel of the service brakes with their Bendix CRM anti-lock system during track acceleration testing.

Using Motometer test equipment, fullpressure stops on dry, clear surfaces told a different story.

Hard applications at 32krn/h made the vehicle jump slightly, while at 481crn/h the offside rear brake locked up and released several times. At 64krn/h there was an exaggerated repeat of this process and the vehicle pulled to the right.

A second attempt at track brake testing, following repairs to a wheel sensor, gave similar results, but this time it was the turn of the front offside wheel to lock up, and at 64km/h the pull to the right was more violent_ Driven in a normal manner this does not affect the handling, but at higher 999 call-out speeds, and when cornering, this wheel-lock could have disastrous consequences for all concerned.

Overall the Brigadier handles well, and on its short wheelbase kerb-to-kerb turning circles of 16.5m it will manoeuvre quite easily, helped by its nicely weighted, power-assisted steering. Its track is wider than normal, but brigade drivers will quickly make allowances when entering driveways or dodging between parked trucks. A narrower 2.28m/track is available as an option.

Several aspects of the Brigadier need some attention, including access to the engine for more detailed service repairs. Being a non-tilting cab daily checks are carried out from inside by raising seat covers and floor panels. RB plans to improve this by incorporating a removeable rear cab bulkhead.

The driver's door lock is also inclined to jam, which would be annoying to say the least for a crew ready to go.

The rev counter fluctuates rather erra

tically in its dismal. surround and the fuel gauge reads a third full when it is actually close on empty.

RB intends to reverse the three wiper arms, which on production models will operate from below the windscreen instead of the top as they tend to droop slightly, especially in cross winds, and distract the driver's attention.

• SUMMARY

Reynolds Boughton (Devon) will soon begin tendering its first B-type appliance and once production begins later in thr. year it expects to sell up to 50 units a year. It will have to compete with the traditional market leader Dennis, as well as Volvo, Renault and Freighter-based chassis and contenders from Scania and MercedesBenz in a market that is only worth about 250 units a year.

Clearly the going will get much tougher, but once its braking ills have been cured and a few minor improvements have been incorporated the Brigadier will be ripe for promotion. In any case, the Reynolds Boughton B-type should have set the alarm bells ringing among the established contenders.

0 by Bryan Jarvis