Tips for Transit discs, bearings

Page 120

If you've noticed an error in this article please click here to report it so we can fix it.

Following our Workshop Ways feature on the second generation Transit, we have received some updated service information concerning the front disc brakes and the wheel bearings

• The Workshop Ways feature on the Ford Transit 100 diesel (Workshop January) included a number of items which called for further clarification or elaboration from the manufacturer.

Using information provided by Ford, the following items give additional details about wheel-bearing adjustment, how to inspect the front disc pad wear.

The other items which caused concern during the feature were two blanking plugs in the engine block which worked loose causing oil leaks. Unfortunately, Ford is still unable to comment on this matter.

Further queries should be addressed to the Ford Customer Service department, Eagle Way, Brentwood, Essex CM13 3BW, or call (0277) 234537.

Ford Transit

WHEEL-BEARING ADJUSTMENT PROCEDURE When adjusting the wheel bearings on the Transit, the wheel-bearing centre nut should be tightened and then adjusted to allow a specified amount of end float. The nut should be tightened to 23 to 34 Nm (17 to 25 lbft) and then backed-off to provide end float of between 0.001 and 0.005.

The correct procedure is to tighten the wheel-bearing adjustment nut (right and left-hand threaded for offside and nearside, respectively) to the specified torque, simultaneously rotating the wheel to ensure the bearings are accurately seated. The nut is then slackened by one flat and the wheel rocked vigorously to settle the bearings.

The wheel is pushed and pulled (not rocked) in a horizontal plane to feel end float in the bearing. If necessary, the nut should be slackened off another flat until end float is felt.

End float is effected by adjustment of the centre nut and checked using a suitable dial gauge.

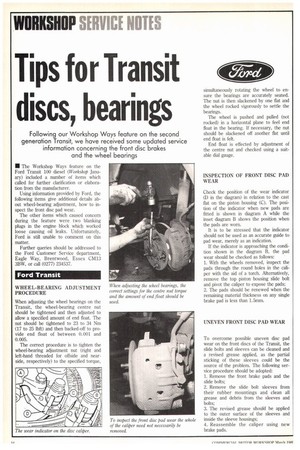

INSPECTION OF FRONT DISC PAD WEAR Check the position of the wear indicator (D in the diagram) in relation to the cast flat on the piston housing (C). The position of the indicator when new pads are fitted is shown in diagram A while the inset diagram B shows the position when the pads are worn.

It is to be stressed that the indicator should not be used as an accurate guide to pad wear, merely as an indication.

If the indicator is approaching the condition shown in the diagram B, the pad wear should be checked as follows: 1. With the wheels removed, inspect the pads through the round holes in the caliper with the aid of a torch. Alternatively, remove the top piston housing slide bolt and pivot the caliper to expose the pads; 2. The pads should be renewed when the remaining material thickness on any single brake pad is less than 1.5mm.

UNEVEN FRONT DISC PAD WEAR To overcome possible uneven disc pad wear on the front discs of the Transit, the slide bolts and sleeves can be cleaned and a revised grease applied, as the partial sticking of these sleeves could be the source of the problem. The following service procedure should be adopted:

1. Remove the front brake pads and the slide bolts;

2. Remove the slide belt sleeves from their rubber mountings and clean all grease and debris from the sleeves and bolts;

3. The revised grease should be applied to the outer surface of the sleeves and inside the sleeve housings;

4_ Reassemble the caliper using new brake pads.