It's quicker by crane haulier

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

REDUCTIONS in the maximum working hours for lorry drivers are compelling hauliers to look much more closely at their overall productivity, and turn-round times will be pared down wherever possible.

For many, this will be a traumatic experience rushed over a

few brief months. Others, like Middlesbrough Transport and Engineering of Eaglescliffe, County Cleveland, have been working on the problem for many years and are already models of efficiency, writes Alan Millar.

MT and E, part of the Bowater Group's Crossley and Sons, carries bricks and tiles from six of the parent company's factories between the Tyne and the Humber, hauling 75 to 80 per cent of their weekly output of two million bricks. Although run along the lines of an own-account operator, MT and E, like its sister company, Teesside Carriers (1963) Ltd, is a member of the Road Haulage Association and is anything but a loss leader for the brick company.

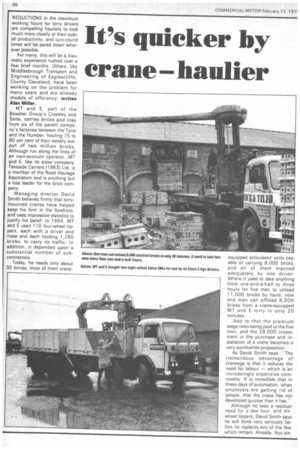

Managing director David Smith believes firmly that lorrymounted cranes have helped keep his firm in the forefront, and uses impressive statistics to justify his belief. In 1954, MT and E used 110 four-wheel tippers, each with a driver and mate and each holding 1,250 bricks, to carry its traffic. In addition, it depended upon a substantial number of subcontractors.

Today, he needs only about 30 lorries, most of them crane equipped articulated units capable of carrying 8,000 bricks, and all of them manned adequately by one driver. Where it used to take anything from one-and-a-half to three hours for five men to unload 11,000 bricks by hand, now one man can offload 8,000 bricks from a crane-equipped MT and E lorry in only 20 minutes.

Add to that the premium wage rates being paid to the five men, and the E9,000 investment in the purchase and installation of a crane becomes a very worthwhile proposition.

As David Smith says: The tremendous advantage of craneage is that it reduces the need for labour — which is an increasingly expensive commodity. It is incredible that in these days of automation, when employers are getting rid of people, that the crane has not developed quicker than it has.'"

Although he sees a residual need for a few fourand sixwheel tippers, David Smith says he will think very seriously before he replaces any of the few which remain. Already, four six

wheelers have been converted into flat-bed brick lorries with cranes, and those which are still in original condition spend much of their lives being used effectively as flat lorries.

The articulated lorries, most of which have a 19-ton carrying capacity, are driven by Class 1 hgv drivers, but Class 2 drivers have been catered for by the purchase of two Scottish-built Volvo F86 eight-wheelers with the same carrying capacity. Their purchase was simply a means of solving the Class 2 men's problem, and there are no plans to buy any more.

F86s form the bulk of the tractive unit fleet, chosen because of their favourable power-to-weight ratio, but there are also Seddon Atkinson 400s, and a DAF 2300 is on order for extended evaluation.

The older trailers are fitted with Hub o 1800 electric cranes which are charged from the lorry's alternator between sites. They have been superseded on later models by Hub o ZHL2000 diesel-driven equipment, and now by Hiab hydraulic units. MT and E intends to buy hydraulic equipment in future.

Added stability is offered on many of the trailers by their Hubo Trackliner rear-steer bogies. MT and E material handling manager Cliff Willetts has a very high regard for the Trackliners, which give brick lorries the turning characteristics of a London taxi. He points out that they can steer with ease through a congested brickyard without damaging their loads or the stacked bricks.

While the Hub o equipment. has offered tremendous advances over previous methods, MT and E feels that equipment such as Hiab's will allow greater flexibility. Cliff Willetts suggests that the company could send one of its own vehicles to Liverpool in company with, say, six artics from a private haulier. The Hiab-equipped vehicle could load and unload bricks from the other vehicles, and then leave them free to carry other traffic on their return journey.

For the future, the company has its eye on increasing vehicle usage by carrying other traffic. By dealing primarily with brickworks at Kibblesworth, near Newcastle, Eldon and Hurworth in Co Durham, Coatham Stob at Eaglescliffe, Kirby Moorside in North Yorkshire, and Broomfleet in North Humberside, it has a tightly defined base area, and has little need to seek traffic elsewhere.

Often, a lorry travelling from Tyneside to a Teesside destination can pick up a return load from the Teesside area brickworks with little empty running. Demand in general is local, but MT and E is engaged in longer distance work to London, the Midlands and Lancashire, and helps serve Crossley's eight depots and 16 builders' and plumbers merchants between Glasgow and King's Lynn in Norfolk. Among ideas being considered to iron out the troughs in the company's work pattern, MT and E is investigating whether it can cater for farmers' demands for land drains in the two months after the harvest. David Smith also believes that crane-equipped vehicles could deal with loads of asbestos, a substance which industry in general is increasingly unwilling to touch by hand.

He also sees a likelihood of work expanding to fill the void left by small tipper operators, 'who will disappear with the tightening of drivers' hours regulations, he thinks.

All of this means that MT and E must continue to strengthen its image of high professional standards, and David Smith says that all of his drivers are given three days' training with an experienced driver before they are allowed to operate crane-fitted brick lorries. Brick work carries some status for a Crossley Group driver, and most of the men are recruited from the general haulage fleet.

After initial training, the new brick driver is eased gently into his new life by being given one or two deliveries at first, often interspersed with distance running, say, to Liverpool.

The five-year-old premises at Eaglescliffe include spacious workshops in which up to eight vehicles can be given pit attention at a time. Cranes, which tend to be kept for up to seven years, are maintained by the company, and it finds that regu

lar maintenance helps make craneage more cost-effective.

David Smith cannot put a figure on what the old system would cost to run today, but doubts very seriously whether he could handle today's volumes of business with manual labour. It would need about twice as many vehicles of

the present size, just to compensate for the increase in terminal times, but his most telling comment is: -It probably would not get done.

He adds: -In transport, we are in business only when we

move things. I believe one of the most serious things facing road haulage is terminal time, and you are not paid to stand around in docks or terminals standing in queues waiting to be unloaded.

He is convinced that many transport operators will think more seriously about cranes, and endorses Cliff Willetts ' opinion_ "Cranes offer dayload rather than payload' It is not so much that the vehicles carry more bricks per journey, but they make more journeys per day and are, consequently, more productive.

I suspect that many more hauliers will take as radical a view of their turnaround times when they consider the productivity improvements achieved by David Smith's business.