Injector with Torsion-bar Return Spring

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

A Résumé of Patent Specifications That Have Recently Been Published

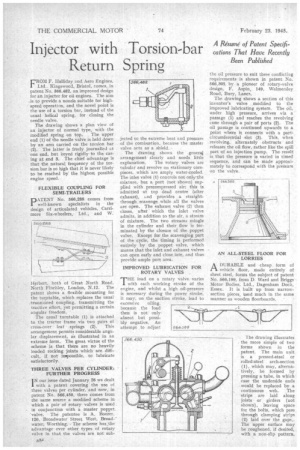

FROM F. Halliday and Aero Engines, Ltd.. Kingswood, Bristol, comes, in patent No. 566,482, an improved desigu for an injector for oil engines. The aim -is to provide a nozzle suitable for highspeed operation, and the novel point is the use of a torsion bar, instead of the usual helical spring, for closing the needle valve.

The drawing shows a plan view of an injector of normal type, with the modified spring on top. The tipper end (1) of the needle valve is held down by an arm carried on the torsion bar (2). The latter is freely journalled at one end, but keyed rigidly to the casing at end 3. The chief advantage is that the natural frequency of the torsion.bar is so high that it is never likely to be reached by the highest possible. engine speed.

FLEXIBLE COUPLING FOR SEMI-TRAILERS DATENT No. 566,288 comes from 1 well-known specialists in the design of articulated vehicles, Carrimore Six-wheelers,• Ltd., and W.

Herbert, both of Great North Road, North Finebley, London, N.12. The patent shows a flexible mounting for the tur,ntable, which replaces the usual trunnioned coupling, transmitting the tractive effort, yet permitting a certain angular freedom.

The usual turntable (1) is attached to the tractor frame via two pairs of cross-over leaf springs (2). This arrangement permits considerable angular displacement, is illustrated in an extreme form. The great virtue of the scheme is that there are no heavily loaded rocking joints which are difficult, if not impossible, to lubricate satisfactorily.

THREE VALVES PER CYLINDER: FURTHER PROGRESS

I N our issue dated January 26 we dealt with a patent covering" the use of three valves per cylinder, and -now, in patent No. 566,450, there comes from the same source a modified scheme in which a pair of rotary valves is used in conjunction with a master poppet 'valve. The patentee is A. Boorer, 120, Broackvater Street West, Broadwater, Worthing. The scheme has the advantage over other types of rotary valve in that the valves are not sub jected to. the extreme beat and pressure of the combustion, because the master valve acts as a shield.

The drawing shows the generai arrangement clearly and needs little

explanation. The rotary valves are tubular and revolve on stationary corepieces, which are amply water-cooled. The inlet valve (1) controls not, only-the mixture, but a port (not shown) supplied with precompressed air; this is admitted at top dead centre (after exhaust), Lnd provides a straight through scavenge, while all the valves are open. The exhaust valve (2) then closes, after which the inlet valve admits, in addition to the air, a stream of mixture. The two streams mingle in the cylinder and their flow is terminated by the closure of the poppet valve. Except for the scavenging part of the cycle, the timing is performed entirely by the poppet valve, which means that the inlet and exhaust valves can open early and close iate, and thus provide ample port area.

IMPROVED LUBRICATION FOR ROTARY VALVES

THE load on a rotary valve varies with each working stroke of the engine, and whilst a high oil-pressure is necessary during the power stroke, it may, on the suction stroke, lead to

excessive oiling, because the load then is not only absent but possibly negative. An

attempt to adjust 566.199

the oil pressure to suit these conflicting requirements is shown in patent No. 566,305. by a, pioneer of rotary-valve design, F. Aspin, 149, Walmersley Road, Bury, Lancs.

The drawing shows a section of this inventor's valve modified to the improved lubricating system. The oil, under high pressure, arrives via a passage (1) and reaches the revolving cone through a pair of ports (2). The oil passage is continued upwards to a point where it connects with a gaitcircumferential slot (3). This, when revolving, alternately obstructs and releases the oil flow, rather like the spill part of an injection pump. The result is that the pressure is varied in timed sequence, and can be made approximately to correspond with be pressure on the valve.

ADURABLE and cheap form of vehicle floor, made entirely of sheet steel, forms the subject of patent No. 566,199, from D Ward and Briggs Motor Bodies, Ltd., Dagenham Dock, Essex. It is built up from narrowsection pieces, used much in the same

manner as wooden floorboards. ' • The drawing illustrates the more simple of two forms shown in the patent. The main unit is a pressed-steel or rolled-steel arch-section (1), which may, alternatively, be formed by pressing a 'tube, in which case the underside ends would be replaced by a continuous web. The strips are laid along joists or girders (not shown), leaving space for the bolts, which pass through clamping strips (2) laid over the gaps„ The upper surface may be roughened, if desired, with a non-slip pattern.