Impressive PERFORMANCE OF A NEW 11-TONNER

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

Under Actual Service Conditions the Fowler Oil engined Six wheeler Demonstrates a Specially Meritorious Rate of Fuel Consumption, Coupled with Safe Control and Robust Construction

IN the summer of 1931 there were introduced two "maximum capacity" four-wheeled lorries with oil engines, bearing the name of John Fowler and Co. (Leeds), Ltd., of Leeds. At Olympia, in November last, the range was extended by the addition of a rigid six-wheeler, intended to carry loads of the order of 11 tons.

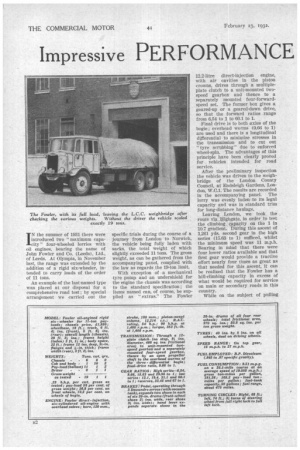

An example of the last-named type was placed at our disposal ' for a comprehensive road test ; by special arrangement we carried out the

specific trials during the course of a journey from London to Norwich, the vehicle being fully laden with sacks, the total weight of which slightly exceeded 11 tons. The gross weight, as can be gathered from the accompanying panel, complied with the law as regards the 19-ton limit.

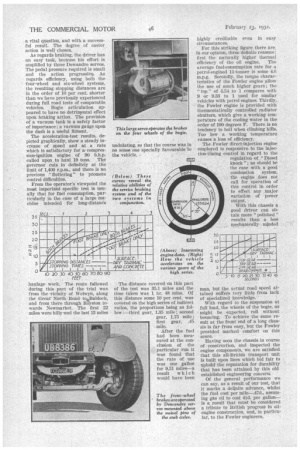

With exception of a mechanical tyre pump and an undershield for the engine the chassis was according to the standard specification; the items named can, of course, be supplied as "extras." The Fowler 12.2-litre direct-injection engine, with air cavities in the piston crowns, drives through a multipleplate clutch to a unit-mounted twospeed gearbox and thence to a separately mounted four-forwardspeed set. The former box gives a geared-up or a geared-down drive, so that the forward ratios range from 6.54 to 1 to 60.1 to 1.

Final drive is to both axles of the bogie ; overhead worms (9.66 to 1) are used and there is a longitudinal differential to minimize stresses in the transmission and to cut out "tyre scrubbing" due to enforced wheel-spin. The advantages of this principle have been clearly proved for vehicles intended for road service.

After the preliminary inspection the vehicle was driven to the weighbridge of the London County Council, at Endsleigh Gardens, London, W.C.1. The results are recorded in the accompanying panel. The lorry was evenly laden to its legal capacity and was in standard trim for long-distance haulage.

Leaving London, we took the route via ,kligligate, in order, to test the climbing capacity on the 1 in 10.7 gradient. During this ascent of 1,261 yds. second gear in the high series (15.63 to 1) sufficed, whilst the minimum speed was 11 m.p.h. Bearing in mind that there were four lower ratios available and that first gear would provide a tractive effort nearly four times as great as that needed for this ascent, it can be realized that the Fowler has a hill-climbing capacity in excess of what would be required for service on main or secondary roads in this country.

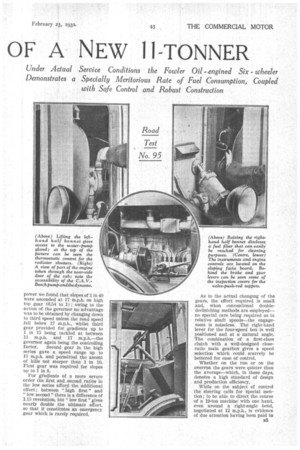

While on the subject of pulling power we found that slopes of 1 in 40 were ascended at 17 m.p.h. on high top gear (6.54 to 1) ; owing to the .action of the governor no advantage was to be obtained by changing down to third speed unless the road speed fell below 17 m.p.h., whilst third

• gear provided for gradients up to 1 in 15 being tackled at between 11 m.p.h. and 17 m.p.h.—the governor again being the controlling

factor. Second gear in the high

• series gave a speed range up to 11 m.p.h. and permitted the ascent of hills not steeper than 1 in 10. First gear was required for slopes -up to 1 in 8.

For gradients of a more severe order the first nn.d _se.cond, ratios in the low series afford the additional effort ; between •" high first" and "low second " there is a difference of 1.15 revolution, but "low first " gives nearly double the ultimate effort, so that it constitutes an emergency gear which is rarely required. As to the actual changing of the gears, the effort required is small and, when conventional doubledeclutching methods are employed-no special care being required as to relative shaft speeds—the engagement is noiseless. The right-hand lever for the four-speed box is well positioned and at a natural angle. The combination of a first-class .clutch with a well-designed closeratio main gearbox gives a speed selection which could. scarcely be bettered for ease of control.

Whether on the run or on the overrun the gears were quieter than the average—which, in these days, denotes a high standard of design and production efficiency.

While on the subject of control the steering calls for special mention; to be able to direct the course of a 19-ton machine with one hand, even around a right-angle bend, negotiated at 12 m.p.h., is evidence of due attention having been paid to

a vital question, and with a successful result. The degree of castor action is well chosen.

As regards braking, the driver has an easy task, because his effort is amplified by three Dewandre servos. The pedal pressure required is small and the action progressive. As regards efficiency, using both the four-wheel and six-wheel systems, the resulting stopping distances are in the order of 10 per cent. shorter than we have previously experienced during full road tests of comparable vehicles. Bogie articulation appeared to have no detrimental effect upon braking action. The provision of a vacuum tank is a safety factor of importance; a vacuum gauge upon the dash is a useful fitment.

The acceleration-test results, depicted graphically, show a steady increase of speed and at a rate which is satisfactory for a. compression-ignition engine of 90 b.h.p. called upon to haul 19 tons. The governor, cuts in definitely at the limit of 1,400 r.p.m., and there is no previous 1'. fluttering" to promote control difficulties.

From the operator's viewpoint the most important specific test is usually that for fuel consumption, particularly in the ease of a large machine intended for long-distance haulage work. The route followed during this part of the trial was from the vicinity of Welwyn, along

• the Great North Road totBaldock,

• and from there through Royston towards Newmarket. The first 22 miles were hilly and the last 13 miles

The distance covered on this part of the test was 35.1 miles and the time taken was 1 hr. 48 DADS. Of this distance some 10 per cent. was covered on the high series of indirect ratios, the proportions being as follow:—third gear, 1.35 mile; second gear, 1.75 mile; first gear, .45 mile.

After the fuel had been measured at the conclusion of the particular run it was found that the rate of use was one gallon for 9,51 miles—a result which would have been highly creditable even in easy circumstances.

For this striking figure there are, in our opinion, three definite reasons ; first the naturally higher thermal efficiency of the oil engine. The average fuel-consumption rate for a petrol-engined 11-tonner is some 4.6 m.p.g. Secondly, the torque characteristics of the Fowler engine allow the use of much higher gears; the " top " of 6.54 to 1 compares with 9 or 9.33 to 1 used for similar vehicles with petrol engines. Thirdly, the Fowler engine is provided with thermostatically controlled radiator shutters, which give a working temperature of the cooling water in the order of 190 degrees F. There is no tendency to boil when climbing hills. Too low a working temperature causes a loss of efficiency.

The Fowler direct-injection engine employed is responsive to the injection-timing control in regard to the regulation of "Diesel knock " ; as should be the case with a good combustion • system, the engine .does not call for operation of this control in order to effect any .major variation of power output.

With this chassis a good driver can obtain more " polished " results than a less mechanically minded man, but the actual road speed attained suffers very little from lack of specialized knOWledge. With regard to the suspension at full load, the wheels of the bogie, as might be expected, roll without bouncing. To achieve the same result at the front end of a long chassis is far from easy, but the Fowler provided marked comfort on this score.

Having seen the chassis in course of construction, and inspected the engine components, we are satisfied that this all-British transport unit is built upon lines which bid fair to uphold the reputation for durability that has been attained by this old established engineering concern.

Of the general performance we can say, as a result of our test, that it marks a definite advance, whilst the fuel cost per mile—.47d., assuming gas oil to cost 4-id. per gallon— is a result that must be considered a tribute to British progress in oilengine construction, and, in particular, to the Fowler engineers.