A WORKSHOP MISCELLANY.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Methods and Devices Adopted by Our Driver and Mechanic Readers.

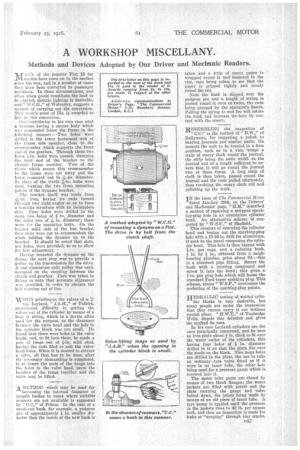

MANY of the popular Fiat 15 ter models have come on to the market since the war, and in a number of cases they have been converted to passenger machines. In these circumstances, and often when goods constitute the load to be carried, electric lighting is desirable, and " W.C.G.," of Wolverley, suggests a method of carrying out the conversion. This week's prize of 15s. is awarded to him in this connection.

Our contributor in his own case used a dynamo having a square body which was suspended below the frame in the following manner :—Two holes were drilled in the lower horizontal web of the frame side member, close to the cross-member which supports the front cud of the gearbox. Through these two holes fin. bolts were passed, clamping the back end of the bracket to the chassis frame member. Two of the rivets which secure this cross-member to the frame were cut away and the holes reamered out to -in. diameter. In place of the rivets kin. bolts were used, forming the two front mounting points of the dynamo bracket.

The bracket itself was made from =114-in. iron, having its ends turned through two right-angles so as to form a box-like structure with an incomplete side. Four holes were drilled in the ends, two being of in. diameter and the other two of /If in. diameter ; these were for the mounting bolts. On the longest solid side of the box bracket four slots were cut to accommodate the studs holding the dynamo up to the bracket. It should be noted that slots, not holes, were provided, so as to allow . for belt adjustment.

Having mounted the dynamo on the frame, the next step was to provide a pulley on the transmission for the drive. A cast-aluminium split pulley was used, mounted on the coupling between the clutch and gearbox. Care was taken in fitting to note that accurate alignment was provided, in order to obviate the belt running out of line. •

wHEN grinding-in the valves of a 2 ton Leyland, "J.A.II.," of Falkirk, experienced difficulty in getting the valves out of the cylinder by means of a loop of string, which is a device often used for the purpose, as the clearance between the valve head and the hole ill the cylinder block was too small. He found that there were holes in the valve heads, and, to fit into these, he made a pair of tongs. out of 1-in. mild steel, having the ends filed to snit the valvehead holes. When it is desired to extract a valve, all that has to be done, after the necessary dismantling is completed, is to insert the ends of the tongs into the holes in the valve head, press the handles of the tangs together and the valve may be lifted.

METHOD which may be used for

increasing the internal diameter of unsplit bushes in cases where suitable reamers are not available is suggested by "0.0.," of Felton. In the ease of a small-end bush, for example, a gudgeon pin of approximately I in. smaller diameter than the inside of the new bush is

taken and a strip of emery paper is ' wrapped round it and mounted in the vice, care being taken to see that the paper is gripped tightly and evenly round the pin.

Next the bush is slipped over the gudgeon pin and a length of string is passed round it once or twice, the ends being grasped by the operator's hands. Pulling the string to and fro will rotate the bush and increase its bore by contact with the emery.

RESEMBLING the" suggestion of "C.0." is the method of "B.W.," of Ballymena, for imparting apolish to bearing journals and similar parts. He mounts the unit to be treated in a firm position, such as in a vice, wraps a strip of emery cloth round the journal, the strip being the same width as the journal and of a length sufficient to ensure that it will go round the journal two or three times. A long strip of cloth is then taken, passed round the journal and the ends pulled alternately, thus revolving the emery cloth roll and polishing up the work.

IN the issue of The Commercial Motor

dated Jantrary 26th, on the Drivers' and Mechanics' page, " RM." described a method of repairing a stripped sparking-plug hole in an aluminium cylinder head. An alternative scheme is suggested by " W.S.F.," of Sheffield.

This consists of removing the cylinder head and boring out the sparking-plug hole with a 15-16-in, drill for aluminium, if such he the metal composing the cylinder head. This hole is then tapped with t-in, gas taps, and a reducing bush. I in. by j in., obtained from a neighbouring plumber, price about 43d.—this is a standard pipe fitting. Smear the bush with a jointing compound and screw it into the head; this gives a fin, gas plug hole which will house the standard Ford taper spairking plug. This scheme, states " W.S.F.," overcomes the pocketing of the sparking-plug points.

IIYDRAULIC testing of welded cylin

der blocks is very desirable, but many people are under the impression that they cannot carry it out without special plant. " II.W.T.," of Tunbridge Wells, dispels this delusion and gives the method lie uses.

In his case Leyland cylinders are the ones principally concerned, and he uses an iron plate about I in, thick to fit over the water outlet of the cylinders, this having four holes of I in. diameter drilled in it so that the plate fits over the studs on the block. Two more boles are drilled in the plate, the one to take an ordinary tyre valve fitted as if it were in an inner tube, the other hole being used for a pressure gauge which is screwed into it.

The water inlet ports are closed by means of two blank flanges; the water jackets are filled with petrol and the plate carrying the gauge and valve bolted down, the joints being made by means of an old piece of inner tube. A tyre pump is applied until the pressure in the jackets rises to 40 lb. per square inch, and then an inspection is made for leaks or "weeping" through tiny cracks. (.345