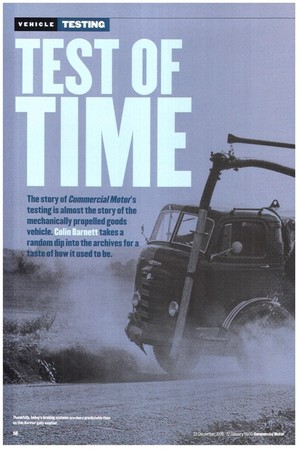

The story of Commercial Motor s testing is almost the story of the mechanically propelled goods

Page 58

Page 59

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

vehicle. .4.14.610 takes a

random dip into the archives for a aste of how it used to be

lthough the Commercial Motor story starts in 1905, the history of organised road testing goes back further. The first issue recalled the editor's presence at trials organised in June 1897 by the Royal Agricultural Society at Crewe. Unfortunately, just one vehifrom the Lancashire Steam Motor Company—turned up and its efforts nearly ended in disaster when the differential seized, causing "a serious disinclination on the part of the car to respond to the steering wheel". The editor had more luck two months later when 15 commercial vehicles turned out for trials at Versailles.

By spring 1898, the British makers were more organised and turned up in force for the first of the Liverpool Self-Propelled Traffic Association's annual trials. CM man was appointed as observer on Thornycroft's articulated five-tonner.

The major vehicles story in CMt first issue compared the merits of horse drawn vs motor vans and steam vs petrol. That first week also saw the launch of the journal's offer for its staff to carry out prepurchase inspections of used goods vehicles for an undisclosed fee.

In the second issue, CM hit the road, if only from the passenger seat, when it joined biscuit maker Peek Frean on Its south London delivery run In a Dennis 1214hp two-cylinder van. An intensive multi-drop route of 25 miles was covered In four-and-a-half hours, a schedule which would be difficult to match today.

The following week was even more ambitious; Chft writer accompanied the delivery of a Lacre 16hp onetonne van from London to Swansea "for the purpose of demonstrating to enquirers in that neighbourhood the capability of their particular vehicle". The 221mile journey was made without stopping the engine and was marked by the writer's apprehension of the wild, uncharted territory beyond Ross-on-Wye. Apart from a stretched throttle cable, reliability was total and fuel consumption was 15.75mpg. The journey was completed in 18 hours, despite running out of food long before the destination. To this day, Chfs testers are mindful of that hard-learnt lesson and never venture out without adequate refreshment for the journey.

CM 's early interest in the world of self-loading cargo carriers was demonstrated by a 1906 journey from London to Edinburgh by a Flat omnibus. Despite such dramas as most of the passengers decamping in search of a Post Office in Grantham and the inability to pass under the arch in Alnwick, the journey was completed in 32hr 6min at an average of 11.6mph, not bad going for a vehicle capable of 20mph flat out.

The dominant force in the testing of commercial vehicles at the start of the century was the War Office. With the likelihood of conflict hanging over the country for years on end, governments displayed remarkable foresight in planning the creation and subsidy of a pool of civilian motorised transport which could be called into active service. Trials were held between 1901 and 1913 to ascertain the suitability of various trucks for military service. But, not for the last time, an apparently sensible policy was criticised for its detail, largely because of the conflicts between civilian and military requirements, as well as the parsimonious nature of the government subsidy offered compared with that in Germany and France.

Despite the flaws, when war did arrive in 1914, the country was at least partly prepared and the value of the motor lorry was proved beyond doubt.

Between the wars

The return from military service of great numbers of both lorries and men trained in their operation was probably the single most significant event in the history of British road haulage. But for the next 10 years or so, technical progress remained sluggish. In particular; the infant compression ignition concept struggled to achieve widespread acceptance.

The Thornycroft Taurus of 1933 was tested with p the latest indirect-injection diesel. This performed well, although the vibration of the 7.55 litre four-pot was commented on. Sometimes CM could be a little too helpful. "In connection with traffic negotiation the steering plays an important part,' it proffered.

Leyland's first diesel engine, also tested in 1933 in the Leyland Bull four-wheeler, was a more advanced item. The 8.1-litre six used an overhead camshaft and direct injection to develop 88hp. Ms view of driving standards was lower then, and we praised the lack of engine timing controls as simplifying matters for those employing drivers of comparatively little intelligence".

At the lower end of the commercial vehicle market was the 1933 Triumph Bhp 5cwt van. With an 832cc engine producing 21hp at 4,000rpm, it offered 55ft3 of load space and rushed from 0 to 40mph in 40 seconds. It had Lockheed hydraulic brakes at each corner, so it could stop as well. Yours for 1125 including the Lucas lighting and starting package.

If that was too much for your pocket, Raleigh would sell you its LDV3 three-wheeled van for £78 15s (178.75). Careful on the hill starts, though, as it was prone to pulling wheelies! Reading of the man who drove the new Raleigh from Nottingham to London for the test reminds us to pay tribute to all of the manufacturers' test drivers without whose help few of these road tests would have happened.

March 1933 saw an Intriguing test of a chain-driven Scammell RC13 six-wheeler. A full test was carried out with a Gardner 61W installed, and the same test was repeated with the engine replaced by Scammell's own four-cylinder petrol unit of comparable size. The diesel was more economical, 10.64mpg against 7.39mpg, and averaged 23.4mph to the petrol's 22.7mph. The downside was the cost, with the Gardner-powered chassis costing £1,840, £395 more than the Scammell petrol.

Lorry drivers needed to be a tough breed then. The test of the Gardner 41W-powered Guy 4-tonner of 1933 observed that "by manual effort two men can get the engine going from cold fairly readily". If that sounded too daunting for wimps, then perhaps the following week's test offered more hope. The Americandesigned Reo 3-tonner had a 268cu in, 75hp petrol engine with a compression ratio ofjust 4.8:1.

Austertty

Appropriately enough, the first vehicle tested after VE Day was a military vehicle, the 6x4 Leyland Hippo which impressed with the mountaineering abilities of its 100hp engine.

In that era, the articulated lorry was still a rarity. The 1946 Dennis Marla was an early pioneer and offered an eight-ton payload from a 13-ton gross weight. The 3,770cc four-pot petrol was made by Dennis and produced 65hp to give a fuel consumption of 10.3mpg and an average speed of 25mph. CM forgot to record the trailer's length, but it would appear to be about 4.5m within an overall length of 8.8m. Road testing was a less strenuous activity in those days, the route totalling 37 miles without travelling more than half a dozen miles from the Guildford factory.

In 1947, the test of a smaller artic, the 10-ton gross Thornycroft Nippy, was used for a thinly veiled attack on contemporary speed limit policy when it was reported that it could brake from the maximum per mitted 20mph in less than its 17ft 5in (5.3m) wheelbase. The respect for this rule was marked by an average speed on test of 23mph. CNs sometimes liberal interpretation of the rule book was owned up to on other occasions, such as doing 67mph around the Stirling area with an Albion Royal Scot bus chassis and running a 1959 Seddon Sirdar six-wheeled rigid at 31.5 tons. Today's testers are a more law-abiding bunch.

Also from Thornycroft in 1947 was an interesting idea that went nowhere in the heavy goods vehicle market—petrol injection. The 7.9litre engine, converted from a 100hp diesel (still known as an oil engine) produced 150hp, enough for a 40mph cruising speed and 6.32mpg. At 22 tons GVW, the 0-20 mph time of 15.4 seconds was less than half that of the oiler.

The CM archives Include the names of numerous manufacturers and their models that have long disappeared—one from the forties is the Proctor Mark 1, built in Mousehold, Norwich. Typical of the 5-6 ton general purpose lorry of the time, the Proctor used a 70hp Perkins P6 diesel and was praised for its acceleration, braking and its spacious, vibration-free cab.

In another report CM purred: "After the first few minutes of driving the van, It was obvious that its acceleration and braking performance exceeded that of many private cars." No, we are not talking about one of the current crop of supervans, but the Austin 25cwt Three-way of 1947. This van has a special memory, a Three-way mobile shop In Radnorshire being the first commercial vehicle that your writer recalls travelling in. its 2,199cc ohs' petrol engine produced 65hp at 3,700rpm and 153Nm of torque at 1,900rpm.

The performance of the four 12-inch twin leading shoe drum brakes caused some excitement during the first emergency stop, from 30mph. "The van stopped sharply, just as though it had met a brick wall. The sandbag load slid along the floor, carrying the toollitt and test equipment with it, and smashed the bulkhead panel." Worse was to coma, as further Investigation revealed the tester's hat had been in front of the load and had preceded its journey through the bulkhead!

The performance testing was carried out at Shelsley Walsh hill climb, where, fully laden, it achieved a time of 2min 5sec for the 1,000-yard dash and successfully restarted on the steepest (1-in-6.2) part in second gear.

A significant factor of the post-war motor industry was the shortage of steel. What steel there was had to be used to make goods to sell for dollars to repay the crippling cost of the war. Aluminium was relatively plentiful, however, and one manufacturer to take advantage was Jensen, Its JNSN six-tonner of 1948 was built on a cruciform ladder chassis fabricated entirely from alloy. Sixteen-inch strips of 14gauge sheet were riveted to two-inch angle sections top and bottom to form l-section members.

Powered by another 70hp Perkins P6, the Jensen weighed about 2 tons unladen to give a payload of 5.5 tons, some 50% better than its ferrous competitors.

Its wheelbase of nearly 5m made for excellent handling, as discovered when the tester was taken by surprise by an unsigned S-bend at an illegal 45mplithe Jensen made it with nothing worse than a bit of tyre squeal.

From the same West Bromwich factory came the Jan-Tug, which probably claims the title of smallestever artic. An 1172cc Ford side-valve pumped out 301hp to carry a 1.5 ton load on a 4m semi-trailer. CMs verdict: "It Is reasonable to expect that the Jon-Tug articulated vehicle could replace two or even three horse-drawn wagons."

In 1953 we tested a vehicle which still appears on today's roads, the Morris (Minor) 5-cwt van with Its new OHV engine. The Morris was praised for Its economy, 41.4mpg overall at maximum weight, but criticised for its stingy glazing—"there were occasions when I opened the rear doors for better visibility when reversing"—a situation made worse by the lack of a nearside mirror.

In the same year, the Foden 8-tanner impressed CMs tester with its 2.7 litre, 84hp two-stroke diesel. So much so that "I was so engrossed by the performance that I neglected to note the time taken during the climb". Perhaps the unaccustomed luxury of the Smiths heater was to blame. Whatever, the 12-ton GVW Foden recorded a respectable 15mpg at an average 25.7mph.

In 1954 was a portent of things to come, with a drive in Sweden of the Volvo Titan 8-tanner. Its economy at high speed and driver comfort over long distances wore envied. As for the performance of the 150hp four-wheeler, the tester's "such acceleration is usually found only in the faster passenger vehicles" and "on my first emergency stop the wheels felt as though they had taken root in the road" tell the story.

Modem times

By the dawn of the motorway era, the state of the art was represented by Foden's 24-ton gross eightwheeler, tested in February 1958. With air brakes on three axles as standard and on four as an option, power steering and a 12-speed gearbox, specifications were beginning to sound familiar to modern ears. There was even the option of a heater, even if it was motivated by preventing drivers over-blanking engines in winter and causing overheating. But if specs were catching up, performance still had a way to go. "Although I had never driven any vehicle up this gradient (1,500 yards, average 1-in-9, max 1-In-3,75) before, I managed to get the Foden to the top In 15min 45sec," said the tester. It scored 5,347 on CHs pro

ductivity index of the day— a good 41-tonner today should reach 16,000 an the same basis.

In 1958 the first Rowe Hillmaster was tested. This Cornish-built 6x4 had an AEC engine and an all-new Eaton-Hendrickson double drive bogie—with its expensive specification we wonder if a second was ever built.

Another effect of the embryonic motorway network was to raise the game for PSVs. The Midland Red 45 was the most modern of its kind, and used the )erater's own turbo-charged eight-litre engine to "ansport 34 passengers from Birmingham to London 3hr 25min (at a cost of E1.06 return!). Ms man rote: "At 75mph it was as steady as a rock, and as mtrollable as the most safe of hand-built sports irs. Passengers who may be perturbed at the !ought of being carried at such a pace need have no !ars." But for those who weren't convinced, there as always the other innovation of an on-board toilet. Testing can sometimes hold nasty surprises for the "inn The first brake test of the 1963 Morris FG iree-tonner was conducted with the windows open. ) problem—until you recall that the FU had the legWary "threepenny bit" cab. This, combined with the ist load of gravel in a low drapside body, meant that ie crew were comprehensively grit-blasted. After iree further test stops (with the windows closed), no ss than 11.5 cwt (580kg) of gravel had been lost.

By the middle of the sixties, the tilt cabs taken for 'anted today were appearing. First was the Leyland tomatic, but it was beaten to a full road test by the ustin FJ five-tonner 01 1965. The advantages of Its tilt rib were relative: "It is not a lengthy process and the ib can be completed in less than 30 minutes," The Ergomatic, in Albion guise, was tested a few eeks later and reduced this time to less than a jrurte. These two were soon joined by Ford's D-series, hich brings us not far from where we are today.

Our 1966 test of the Gemmel' 1500 Automatic preqted that "automatic transmission must become the de on light delivery vehicles", but buyers remained nconvinced. it Is only now with Vauxhall's Astravan in le light sector, Allison's 1000-Series for 7.5-tormers rid a whole raft of heavies that self-changing gears resent a practical proposition.

By 1966, the haulage scene that most of today's )aders would recognise was being formed, and saw lir first Scania test. The Scania-Vabis 1.876H Super aided a flat York triaxle trailer at 32 tons. The 237hp mbo-diesei rig gave an overall figure of between .5mpg and 7.5mpg. But there was still room for nprovement-despite 10.5 tons on the drive axle, the cania needed the cliff lock for a hill start in reverse, ad brakes and synchromesh received some criticism. ut on the positive side driver comfort was described s "impeccable" and the cab doors had a "Rolls-Royceke action".

Predicting a move that took longer than expected ) materialise, CM obtained a dispensation in 1966 to 1st a Fiat 693T at 38 tons. With just 208hp available sem its naturally aspirated direct-injection six, the x4 tractor produced 6.3mpg, despite gearing that awe a top speed of just 41mph.

Methodology

As vehicles have improved, so have CMs test methods, but probably the greatest improvement has been the use of fixed routes for fuel testing. For many years, vehicles were usually tested on routes near each maker's premises, so performance figures could not be compared between different makes. One exception was in the late forties, when a proliferation of battery electric delivery vehicles (or milk floats to you and me) gave rise to seine extravagant claims on power consumption. To settle matters, CMs technical editor insisted on a standard multi-drop route for all vehicles. He was to regret this after 22 miles of "dogged plodding" behind a pedestrian-controlled electric truck with a "jumbo battery".

Today, not only are tests conducted over the same routes, but efforts are made to ensure that conditions are similar. The same fuel pumps and rest halts are used and the tests are normally run at the same time of day. If circumstances change, for example due to bad weather or mechanical defects, the test will be aborted. To lessen the impact of an aborted test run, fuel, time and distance readings are taken at regular points on the longer routes so that testing can be resumed without running the whole distance again.

For years, fuel flow was measured using a small secondary gravity tank, often mounted In the cab. This was fine with simple petrol engines (ignoring the obvious safety issues) but diesels, with their sealed-to-atmosphere systems and return feeds, made this impractical.

Nowadays, test vehicles larger than 3.5 tonnes 011W are normally fitted with fuel flow meters. Although these are used to obtain interim figures, the definitive fuel figures are obtained by filling the tank to an accurately measured level at the same pump at start and finish, This is easy enough on large vehicles, but many modern smaller vehicles have complex breather systems which need to be purged. One recent van took more than 20 minutes to fill accurately; a patience-testing process but essential for meaningful results.

Brake testing has also changed. First there was the simple tape measure; this was refined by using a chalk gun to mark the road at the point of brake application, although this method became so popular at the MIRA proving ground that individual marks were difficult to identify. It was replaced by the Motometer, a box of tricks which scribed the results on to waxed paper. Today we use the Turnkey Brakesafe, which sits on the passenger seat or floor and works electronically, printing out the test results instantly.

Throughout its history, Chfs road testing has been guided by the phrase "minimise the variables". In the crucial maximum-weight sector, this principle has been greatly helped by the use of our own dedicated semi-trailers.

The first CM trailer, a 40ft Crane Fruehauf flat, entered service in 1977 while the most recent arrived earlier in 1999. Still made by Fruehauf, the 13.6m curtainsider with Its three air-suspended and discbraked axles represents the state of the art.

Performance testing, meanwhile, is much the same as ever. Check speedo accuracy over a known distance, then do the acceleration tests on a flat road against a stopwatch. Only the accuracy of the test track flatness and the type of watch, digital now instead of clockwork, have changed. Hill climbs, too, are recognisable, although mechanical reliability is (almost) taken for granted to the point that we no longer stop at the top of each hill to check oil and water temperatures with a brass thermometer (brass being specified after the original glass item burst Inside a rear axle).

The future

CMs testing is very much an evolutionary thing, constantly having to respond to changes in vehicles and road conditions.

The most recent changes forced upon us affected the Scottish route. The imposition of a 25-tonne weight restriction on a bridge in Edinburgh means that we can no longer use the city centre, while the unannounced appearance of a traffic island at the bottom of the infamous Black Hill, near Consett, coincided with the arrival of 41-tonne, six-axled artics and forced another detour. Fortunately in the latter case the obvious alternative, Castleside, is an equally demanding challenge.

The next anticipated change, to our Kent light van route, is likely to be as a result of vehicle improvements. Until as recently as 18 months ago, the M20 climb up Wrotham Hill presented a measurable challenge to most vans. However, the recent spate of high power outputs means that it is now the norm for vans to storm up at 70mph, even fully loaded. The same thing is true for the A20 sprint up Farningham Hill, where speeds usually have to be held back within the legal limits.

We have already tested various gas and electric commercial vehicles, and can look forward to innovations such as hydrogen fuel cells before much longer. But whatever the future brings, CM intends to be here to bring you the facts and figures.