Artic or drawbar: which rig is best for you?

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

by Bill Brock • Changes in UK operating weights for drawbar outfits are just around the corner even though formal introduction of standard Euro-legislation for vehicle couplings is still 18 months away.

The raising of their gross train weights to 35 tonnes has proven popular and a further increase to 38 tonnes in the New Year will cause many operators to look more closely at the alternative to running articulated vehicles.

Drawbars are also to be permitted to operate at 44 tonnes, to and from railheads but just as the articulated outfit needs five axles at 38 tonnes and six at 44, so too does the drawbar.

However, the key to 44-tonne operation however is road friendly suspension which is also required on the drive axle of a drawbar at 35 tonnes.

Which suits an individual operation is best left to the operator, but there's some sound advice from Roger Darling, sales manager of VI3G, maker of coupling equipment for both types of combinations. He claims unbiased views of the strengths and weaknesses of both systems.

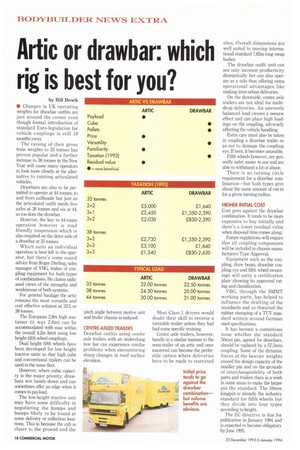

For general haulage the artic remains the most versatile and cost effective solution at 32.5 or 38 tonnes.

The European 2.9m high container (it was 2.6m) can be accommodated with ease within the overall 42m limit using low height fifth wheel couplings.

Dual height fifth wheels have been developed for low height tractive units so that high cube and conventional trailers can be used in the same fleet.

However, where cubic capacity is the major priority, drawbars win hands down and can sometimes offer an edge when it comes to payload.

The low-height tractive unit may have some difficulty in negotiating the humps and bumps likely to be found at some delivery or collection locations. This is because the cab is closer to the ground and the sites. Overall dimensions are well suited to moving international standard 7.82m-long swap bodies.

The drawbar outfit unit can not only increase productivity dramatically but can also operate as a solo thus offering extra operational advantages like making inter-urban deliveries.

On the downside, centre axle trailers are not ideal for multidrop deliveries. An unevenly balanced load causes a seesaw effect and can place high loadings on the coupling, adversely affecting the vehicle handling.

Extra care must also be taken in coupling a drawbar trailer so as not to damage the coupling eye. If bent, it becomes unusable.

Fifth wheels however, are generally safer, easier to use and are able to withstand a lot of abuse.

There is no turning circle requirement for a drawbar combination—but both types give about the same amount of cut-in for a given turning radius.

HIGHER INITIAL COST Cost goes against the drawbar combination. It tends to be more expensive to buy initially and there's a lower residual value when disposal time comes along.

Future regulations will require that all coupling components will be included in chassis manufacturers Type Approval.

Equipment such as the coupling, draw beam, drawbar coupling eye and fifth wheel mountings will carry a certification plate showing its approved rating and classification.

VBG, through the SMMT working party, has helped to influence the drafting of the standards and so thwarted the rubber stamping of a TUV standard written around German steel specifications.

It has become a contentious issue whether the standard 50mm pin, agreed for drawbars, should be replaced by a 57.5mm coupling. Some of the dynamic forces at the heavier weights exceed the design capacity of the smaller pin and on the grounds of interchangeability of both parts and trailers there is a wish in some areas to make the larger pin the standard. The 50mm kingpin is already the industry standard for fifth wheels but they divide into four types according to height.

The EC directive is due for publication in January 1994 and is expected to become obligatory by June 1995.