Combining Utility and Refiner nt in Commercial Body Design

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

Our Bodybuilding Expert Deals with Sliding Cab-doors, Hard-wearing Floors, Rear Cross -bracing and Methods of Raising the Roof

Centre

41 OULD 1 have sliding doors

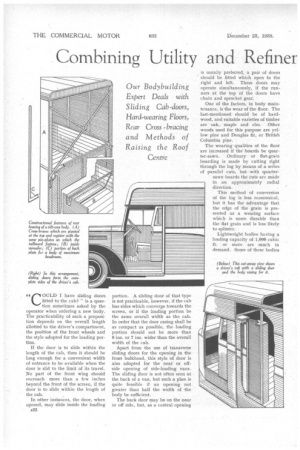

fitted to the cab? "is a ques tion sometimes asked by the operator when ordering a new body. The practicability of such a proposition depends on the overall length allotted to the driver's compartment, the position of the front wheels and the style adopted for the loading portion.

If the door is to slide within the length of the cab, then it should be long enough for a convenient width of entrance to be available when the door is slid to the limit of its travel. No part of the front wing should encroach more than a few inches beyond the front of the screen, if the door is to slide within the length of the cab.

In other instances, the door, when opened, may slide inside the loading A22

portion. A sliding door of that type is not practicable, however, if the cab has sides which converge towards the screen, or if the loading portion be the same overall width as the cab. In order that the door casing shall be as compact as possible, the loading portion should not be more than 6 ins. or 7 ins, wider than the overall width of the cab.

Apart from the use of transverse sliding doors for the opening in the front bulkhead, this style of door is also adopted for the near or offside opening of side-loading vans. The sliding door is not often seen at the back of a van, but such a plan is quite feasible if an opening not greater than half the width of the body be sufficient.

The back door may be on the near or off side, but, as a central opening is usually preferred, a pair of doors should be fitted which open to the .right and left. These doors may operate simultaneously, if, the runners at the top of the doors have chain and sprocket gear.

One of the factors, in body maintenance, is the wear of the floor. The last-mentioned should be of hardwood, and suitable varieties of timber are oak, 'maple and elm. Other woods used for this purpose are yellow pine and Douglas fir, or British Columbia pine.

The wearing qualities of the floor are increased if the boards be quarter-sawn. Ordinary or fiat-grain boarding is made by cutting right through the log by means of a series of parallel cuts, but with quartersawn boards the cuts ara made in an approximately radial direction.

This method of conversion of the log is less economical, but it has the advantage that the edge of the grain is presented as a wearing surface which is more durable than the flat grain and is less likely to splinter.

Lightweight bodies having a loading capacity of 1,000 cubic ft. or more are much in demand. Some of these bodies have 9 ft, or more of headroom and have a light superstructure above the waist, consisting of a tilt and hoops, whilst above the tailboard there is a pair of waterproof curtains.

The front of the body is made rigid by close-boarding, and at the back the large tilt is prevented from swaying by wide back pillars and a deep board across the top of the opening.

When back doors are fitted, these are sometimes fastened by a bar which crosses the door

diagonally. It is suggested that a similar kind of fastening could he used for a van without back doors.

In this instance, there would be a pair of bars, pivoted at the top, and with eyes at the bottom registering with the pins or dowelplates which• form part of the tailboard fasten

ing. These bars, apart from any protection afforded to the load, would function. as cross braces and so increase the rigidity of the back of thebody:

• The rigidity of a large tilt or boxvan body is also increased if two or more removable spreaders be fitted between the sides of the body. These may be similar to the spreaders used to connect the tops of the loading racks of market-gardeners' wagons, and may have dowels or pins, at the ends, which drop into staples • at the waist or at a higher level.

The back of the body is usually

reinforced with a U-shaped plate secured on the bottom -of the body, below the tailboard, and has flaps running up each back pillar. Often these pillar-flaps are not extended above the waist, but with a high van it would be an advantage if they were carried up nearer to the roof and webs inserted in the lower corners of the plates.

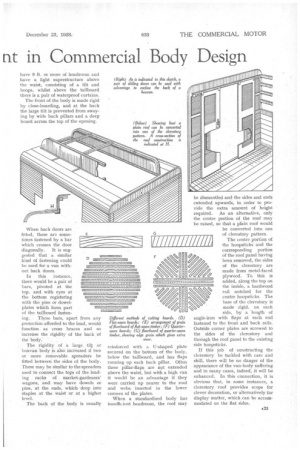

When a standardized body has insufficient headroom, the roof may be dismantled and the sides, and ends extended upwards, in order to provide the extra amount of height required. As an alternative, only the centre portion of the roof may be raised, so that a plain roof would be converted into one of clerestory pattern.

The centre portion of the hoopsticks and the corresponding portion of the roof panel having been removed, the sides of the clerestory are made from metal-faced plywood. To this is added, along the top on the inside, a hardwood rail notched for the centre hoopsticks. The base of the clerestory is made rigid, on each side, by a length of angle-iron with flaps at each end fastened to the front and back rails. Outside corner plates are screwed to the sides of the clerestory and through the roof panel to the existing side hoopsticks.

If this job of constructing the clerestory be tackled with care and skill, there will be no danger of the appearance of the van-body suffering and in many cases, indeed, it will be enhanced. In this connection, it is obvious that, in some instances, a clerestory roof provides scope for clever decoration, or alternatively for display matter, which can be accommodated on the fiat sides.