TENDENCIES IN CHASSIS DESIGN

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

IN last week's issue we gave the first instalment of this article, the object of which is to review the lines of progress which chassis designers are taking and, by that means, to formulate ideas as to likely developments in the future. Our first instalment dealt with chassis frames.

We will now turn to a consideration of engine design and it will here be necessary first of all to hold an

inquest, as it were, into the relative merits of four, six and eight-eylindered petrol engines. At the present time there seems to be no settled policy for any, class of vehicle other than the luxury coach, and in this grade the only feature common to most snakes of machine is that the power units are almost entirely of the sixcylinder type. In the 15-cwt. to 2-ton range, for example, certain makes employ four-cylindered engines and others " sixes " and there is no standardization of power for loading capacity. This state of affairs naturally gives .a prospective purchaser a wide choice of type, but it' is not exactly economic so, far as production is concerned.

Many light-2:goods chassis are powered by sixeylindered engines of between 20 h.p. and 30 h.p. R.A.C. rating, and even with loads up to capacity—i.e., about B40 30 cwt.—the performance is more on a par with that of a pleasure car than with that of a lorry. It is, of course, undesirable that heavy goods vehicles (of the 6-ton to 12-ton types) should have similar performance, for inertia loads due to fast cornering and so on would be disastrous. It follows, therefore, that there are certain classes of work even among the smaller types of machine which, in the interests of economic operation, call for a moderate power-weight ratio.

Turning now to an analysis of in e c h anical features, we find, in large passenger chassis powered by six

An efficient side. valve unit — t h e Crossley. This sectional view shows how adequate water contact has

been obtained.

cylinder unit s, that sturdiness forms the basic characteristic of design. The crankcases are deep, of wide section and stiffly

webbed to carry the intermediate journals of a seven bearing crankshaft.

In the past many engines have suffered from torsional vibration of the crankshaft, the main effect of which has been to give a " rumble " to the whole vehicle when the engine is pulling hard at its point of maximum torque which, in many up-to-date power units, lies around 1,400 r.p.m. Nowadays trouble from this cause is seldom experienced, because engineers have really got down to sound crankshaft design and have provided amply thick webs for each of the six throws.

The Objections to the "Straight Eight."

The eight-cylindered engine with cylinders in line has not made much progress in this country so far as commercial vehicles are concerned, very largely on account of its length, and objections are even now being raised concerning the length of six-cyliridered engines, because, as a rule, the longitudinal overall dimension is fixed by the essential length of the crankshaft (to give adequate torsional strength and ample bearing surfaces for all the main and connecting-rod journals), and not by dimensional considerations of cylinder bore.

One way out of the difficulty would be to employ eight cylinders mounted V-wise on a common crank case, so that the unit would have all the advantages of light reciprocating parts, good mechanical balance (if the angle of the V were set at 90 degrees), and quite good firing balance; also, such a design would lend

itself to efficient mixture distribution. This engine would, of course, be of moderate overall height and would be considerably shorter than a four-cylindered unit giving the same b.h.p. at the flywheel, which is a point to. be borne well in mind.

Such a suggestion as this is, of course, not new, because many hundreds of aero engines of this kind have been used both during and since the war, whilst, in America, at any rate, the layout is a

very popular one at the present time for pleasure cars. There does not yet seem to be any settled policy regarding valve gear, for certain makers assert that the side-by-side type with its simple layout can, provided the combustion-chamber shape be properly arranged, he just as efficient as an overhead-valve type,

and evenif there be a slight loss in thermal or volumetric efficiency the ease with which decarbonizing etc., are effected counterbalances this.

The Sleeve-valve Principle.

The sleeve-valve engine, of which the Daimler Co., Ltd., is the outstanding exponent on the commercialvehicle side of the automobile industry, is unquestionably a highly efficient type, and now that the matter of sleeve inertia has been solved by manufacturing these components from a special grade of steel the power delivered compares favourably with any other design.

At one time, of course, excessive oil consumption was experienced, but now that aluminium alloys have been produced with a very low heat-expansion rate, pistonsleeve clearances have been reduced, a fact which, together with a redistribution of oiling grooves in the sleeves themselves, has removed this complaint.

Because no valve adjustment in any shape or form is required, the sleeve-valve design is exceptionally well suited to multi-cylindered engines, and there can be no doubt that this characteristic has been prominently before the Daimler designers when they produced the double-six power unit for private cars. Although the

V-type 12-cylindered engine would not be materially shorter than a six-cylindered engine of equal power, the sleeve-valve 'eight," with cylinders arranged V-wise, would form an ideal design.

There is no doubt that hemispherical combustion chambers are less prone to "pinking" than any other type of combustion chamber at present in

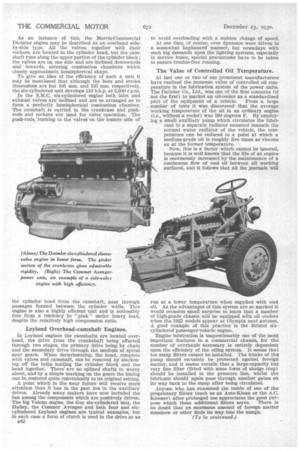

extensive use, but until recently most designs have had the objectionable feature of complication in dismantling due to the one or two overhead camshafts. Manufacturers have realized this and have taken steps to avoid it. As an instance of this, the Morris-Commercial Dictator engine may be described as an overhead sideby-side type. All the valves, together with their rockers, are located in the cylinder head, but the camshaft runs along the upper portion of the cylinder block ; the valves are on one side and are inclined downwards and inwards, entering combustion chambers which closely approximate hemispherical shape.

To give an idea of the efficiency of such a unit it may be mentioned that although the bore and stroke dimensions are but 105 ram. and 135 mm. respectively, the six-cylindered unit develops 110 b.h.p. at 2,600 r.p.m.

In the S.M.C. six-cylindered engine both inlet and exhaust valves are inclined and are so arranged as to form a perfectly hemispherical combustion chamber. The camshaft is carried in the crankcase and pushrods and rockers are used for valve operation. The push-rods,'running to the valves on the remote side of the cylinder head from the camshaft, pass through passages formed between the cylinder walls, This engine is also a highly efficient unit and is noticeably free from a tendency to " pink " under heavy load, despite the relatively high compression ratio.

Leyland Overhead-camshaft Engines.

In Leyland engines the camshafts are located overhead, the drive from the crankshaft being effected through two stages, the primary drive being by chain and the secondary drive through the medium of spiral spur gears. When decarbonizing, the head, complete with valves and camshaft, can be removed by slackening off the bolts holding the cylinder block and the head together. There are no splined shafts to worry about, and by a simple marking on the gears the timing can be restored quite conveniently to its original setting.

A point which in the near future will receive more attention than it has in the past lies in the auxiliary drives. Already many makers have now included the fan among the components which are positively driven. The big Vulcan engine, the Guy six-cylindered unit, the Halley, the Cotamer Avenger and both four and sixcylindered Leyland engines are typical examples, but in each ease a form of clutch is used in the drive so as n42 to avoid overloading with a sudden change of speed.

At one time, of course, even dynamos were driven in a somewhat haphazard manner, but nowadays with such big demands upon the lighting systems, especially in service buses, special precautions have to be taken to ensure trouble-free running The Value of Controlled Oil Temperature.

At last one or two of our prominent manufacturers have realized the immense value of controlled oil temperature in the lubrication system of the power units. The Daimler Co., Ltd., was one of the first concerns (if not the first) to market an oil-cooler as a standardized part of the equipment of a vehicle. From a large number of tests it was. discovered that the average working temperature of the oil in an ordinary engine (i.e., without a cooler) was 190 degrees F. By employing a small auxiliary pump which circulates the lubri cant to a separate radiator mounted beneath the • normal water radiator of the vehicle, the temperature can be reduced to a point at which a • medium-grade oil is roughly five times as viscous as at the former temperature.

Now, this is a factor which cannot be ignored, because it is well known that the life of an engine is enormously increased by the maintenance of a continuous flow of cool oil between all working surfaces, and-it follows that all the journals will

run at a lower temperature when supplied with cool oil. As the advantages of this system are so marked it would occasion small surprise to learn that a number of high-grade chassis will be equipped with oil coolers when the, 1932 models appear at Olympia next autumn. A good example of this practice is the Bristol sixcylindered passenger-vehicle engine.

Engine lubrication is unquestionably one of the most important features in a commercial chassis, for the number of overhauls necessary is entirely dependent upon the efficiency of the oiling system. It seems that too many filters cannot be installed. The intake of thi pump should certainly be protected against foreign matter, and it seems certain that a large-capacity but very fine filter (fitted with some form of sludge trap) should be installed in the pressure line, whilst the lubricant should again pass through another gauze on its way back to the sump after being circulated.

Anyone who has examined the inside of one of the proprietary filters (such as an Auto-Klean or the A.C. Kleener) after prolonged use appreciates the good purpose which these additional filters serve. There is no doubt that an enormous amount of foreign matter somehow or other finds its way into the sumps.