Next to godliness

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

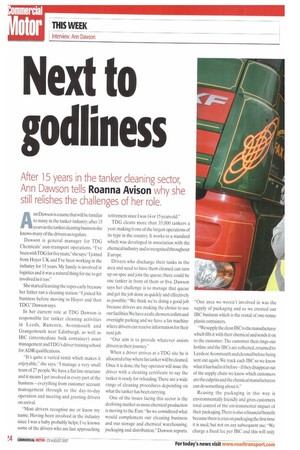

After 15 years in the tanker cleaning sector, Ann Dawson tells Roanna Avison why she still relishes the challenges of her role.

Ann Dawson is a name that will be familiar to many in the tanker industry; after 15 years in the tanker cleaning business she knows many of the drivers as regulars.

Dawson is general manager for TDG Chemicals non-transport operations. -I've been withTDG for five years," she says."I joined from Hoyer UK and I've been working in the industry for 15 years. My family is involved in logistics and it was a natural thing for me to get involved in it too."

She started learning the ropes early because her father ran a cleaning station: "I joined his business before moving to Hoyer and then TDG," Dawson says.

In her current role at TDG Dawson is responsible for tanker cleaning activities in Leeds, Runcorn, Avonmouth and Grangemouth near Edinburgh, as well as IBC (intermediate bulk container) asset management and TDG 's driver training school for ADR qualifications.

"It's quite a varied remit which makes it enjoyable," she says. "I manage a very small team of 27 people. We have a flat line structure and it means I get involved in every part of the business everything from customer account management through to the day-to-day operation and meeting and greeting drivers on arrival.

-Most drivers recognise me or know my name. Having been involved in the industry since I was a baby probably helps; I've known some of the drivers who are fast approaching retirement since I was 14 or 15 years old."

TDG cleans more than 35,000 tankers a year, making it one of the largest operations of its type in the country. It works to a standard which was developed in association with the chemical industry and is recognised throughout Europe.

Drivers who discharge their tanks in the area and need to have them cleaned can turn up on spec and join the queue; there could be one tanker in front of them or five. Dawson says her challenge is to manage that queue and get the job done as quickly and effectively as possible: "We think we're doing a good job because drivers are making the choice to use our facilities.We have a cafe,showers,toilets and overnight parking and we have a fax machine where drivers can receive information for their next job.

"Our aim is to provide whatever assists drivers in their journey."

When a driver arrives at a TDG site he is allocated a bay where his tanker will be cleaned. Once it is done, the bay operator will issue the driver with a cleaning certificate to say the tanker is ready for reloading. There are a wide range of cleaning procedures depending on what the tanker has been carrying.

One of the issues facing this sector is the declining market as more chemical production is moving to the East. "So we considered what would complement our cleaning business and our storage and chemical warehousing, packaging and distribution," Dawson reports. -One area we weren't involved in was the supply of packaging and so we created our IBC business which is the rental of one-tonne plastic containers.

"We supply the clean IBC to the manufacturer which fills it with their chemical and sends it on to the customer. The customer then rings our hotline and the IBCs are collected, returned to Leeds or Avonmouth and cleaned before being sent out again. We track each IBC so we know what it has had in it before-if they disappear out of the supply chain we know which customers are the culprits and the chemical manufacturers can do something about it."

Reusing the packaging in this way is environmentally friendly and gives customers total control of the environmental impact of their packaging.There is also a financial benefit because there is a tax on packaging the first time it is used, but not on any subsequent use. "We charge a fixed fee per IBC and this will only change if we don't get them back," Dawson says."We see it as a progression from the tanker cleaning and as our market there diminishes we are filling it with the next size of container.And operationally for us it means that in the quiet times when there are not many tankers in we can he cleaning the IBCs."

TDG's bay operators receive six months of initial training, and every year their skill level is assessed: "As a result our accident stats are extremely low — less than one in 100,000 for tankers and one in 200,000 for IBCs — and I put that down to the intensive training and continual dialogue between the bay operators and the management.

"Everyone has a right to say something and come up with new ideas and we take on board comments and ideas from the drivers too."

Despite the declining market for tanker cleaning.in 2003TDG spent f1.5m redeveloping its Leeds and Runcorn sites; the following yearit invested a further f500,000 at Avonmouth and Grangemouth.

One of the reasons for this is that the environmental legislation governing the sector becomes tighter every year. Dawson says it's a challenge to remain compliant, and the cost of effluent disposal is increasing at 5% over RP1. "The cost of gas has also increased hugely in the last five years and in a decreasing market it is a challenge to remain profitable and keep the business healthy for the long term," she adds.

Dawson's other area of responsibility is training. "TDG was one of the first driving schools to offer ADR qualifications," she says. "All drivers who deal with hazardous chemicals need to take the ADR exam every three years. We offer that training to drivers in Leeds and Warrington and we have a dedicated trainer who runs those courses.We train about 250-300 drivers a year." TDG recently added DGSA training to its repertoire,catering for supervisors at companies handling chemicals. "We've done one course so far and are just waiting for the exam results. We plan to run another in September," says Dawson. Some of the drivers using the cleaning bays also use TDG training services:"We have different product offerings going into the same customer base."

Training is a vital part of the job, even for Dawson. "I'm not a chemist," she says, "I've picked it up as I've gone along. It's good to have an understanding but it takes a very long time to learn this industry. It's still made up of family businesses and owner-operators and the knowledge is passed down the family line.

"I'm constantly learning because the industry is evolving. There's always new technology and different cleaning agents available, and of course we're now looking at the environmental impacts and cost."