HOLLAND'S VICTORIAN VALUES

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

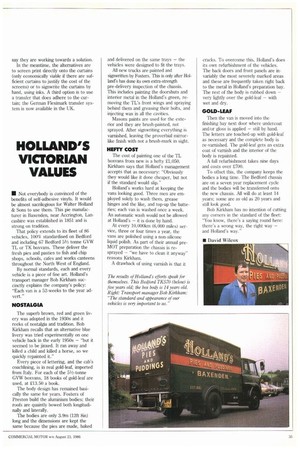

• Not everybody is convinced of the benefits of self-adhesive vinyls. It would be almost sacrilegious for Walter Holland Si Sons to use them. This pie manufacturer in Baxenden, near Accrington, Lancashire was established in 1851 and is strong on tradition.

That policy extends to its fleet of 86 vehicles, 100% standardised on Bedford and including 67 Bedford 51/2 tonne GVW TL or TK boxvans. These deliver the fresh pies and pasties to fish and chip shops, schools, cafes and works canteens throughout the North West of England.

By normal standards, each and every vehicle is a piece of fine art. Holland's transport manager Bob Kirkham succinctly explains the company's policy: "Each van is a 52-weeks to the year advert."

NOSTALGIA The superb brown, red and green livery was adopted in the 1930s and it reeks of nostalgia and tradition. Bob Kirkham recalls that an alternative blue livery was tried experimentally on one vehicle back in the early 1950s — "but it seemed to be jinxed. It ran away and killed a child and killed a horse, so we quickly repainted it."

Every piece of lettering, and the cab's coachlining, is in real gold-leaf, imported from Italy. For each of the 51/2-tonne GVW boxvans, 18 books of gold-leaf are used, at 213.50 a book.

The body design has remained basically the same for years. Fosters of Preston build the aluminium bodies: their roofs are quaintly bowed both longitudinally and laterally.

The bodies are only 3.9m (12ft 8in) long and the dimensions are kept the same because the pies are made, baked and delivered on the same trays — the vehicles were designed to fit the trays.

All new trucks are painted and signwfitten by Fosters. This is only after Holland's has done its own extra-strength pre-delivery inspection of the chassis. This includes painting the d(x)rshuts and interior metal in the Holland's green, removing the TL's front wings and spraying behind them and greasing their bolts, and injecting wax in all the cavities.

Masons paints are used for the exterior and they are brush-painted, not sprayed. After signwriting everything is varnished, leaving the proverbial mirrorlike finish with not a brush-mark in sight.

HEFTY COST The cost of painting one of the TL boxvans from new is a hefty £1,050. Kirkham says that Holland's management accepts that as necessary: "Obviously they would like it done cheaper, but not if the standard would slip."

Holland's works hard at keeping the vans looking good. Three men are employed solely to wash them, grease hinges and the like, and top-up the batteries; each van is washed once a week. An automatic wash would not be allowed at Holland's — it is done by hand.

At every 10,000km (6,000 miles) service, three or four times a year, the vans are polished using a non-silicone liquid polish. As part of their annual preMOT preparation the chassis is resprayed — "we have to clean it anyway" reasons Kirkham.

A drawback of using varnish is that it cracks. To overcome this, Holland's does its own refurbishment of the vehicles. The back doors and front panels are invariably the most severely marked areas and these are frequently taken right back to the metal in Holland's preparation bay. 'rhe rest of the body is rubbed down — very lightly over the gold-leaf — with wet and dry.

GOLD-LEAF

Then the van is moved into the finishing bay next door where undercoat and/or gloss is applied — still by hand. The letters are touched-up with gold-leaf as necessary and the complete body is re-varnished. The gold-leaf gets an extra coat of varnish and the interior of the body is repainted.

A full refurbishment takes nine days and costs over 2700.

To offset this, the company keeps the bodies a long time. The Bedford chassis are on a seven year replacement cycle and the bodies will be transferred onto the new chassis. All will do at least 14 years; some are as old as 20 years and still look good.

Bob Kirkham has no intention of cutting any corners in the standard of the fleet: "You know, there's a saying round here: there's a wrong way, the right way — and Holland's way."

• David Wilcox