U.S. Capital Turns to Britain

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

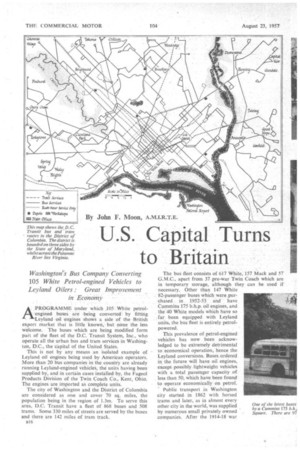

Washington'S Bus Company Converting 105 White Petrol-engined Vehicles to Leyland Oilers. Great Improvement in Economy -- AI :PROGRAMME under which ,105. White petrolengine& .buseS.. are -being converted . by fitting Leyland oil -engines shoWS a side of the •British export market that is little known, • but nOne the Iess welcome. The buses which are being modified form part of the fleet of the D.C. Transit Systern, Inc., who operate all the urban bus and tram services in Washington, DE., the capital of the United States.

This is not by any means an isolated example of Leyland oil engines being used by American operators. More than 20 bus companies in the.country are already running Leyland-engined vehicles, the units having been supplied by, and in certain cases installed by, the Fageol Products Division of the Twin Coach Co., Kent, Ohio.

The engines are imported as complete units.

The city of Washington and the District of Columbia arc considered as one and cover 70 sq. miles, the population being in the region of 1.3m. To serve this area, D.C. Transit have a fleet of 868 buses and 508 trams. Some 330 miles of streets are served by the buses and there are 142 miles of tram track.

B16 This prevalence of petrol-engined vehicles has now been acknowledged to be extremely detrimental to economical operation, hence the Leyland conversions. Buses ordered in the future will have oil engines, except possibly lightweight vehicles with a total passenger capacity of less than 50, which have been foundto operate economically on petrol.

Public transport in Washington city started in 1862 with horsed trams and later, as in almost every other city in the world, was supplied by numerous small privately owned companies. After the 1914-18 war these .Companies were gradually merged into three main concerns, which formed the basis of the Capital Transit Co., founded in 1933.

All the existing fleet was purchased by the Capital Transit Co., the oldest buses still in service being a White and a Twin Coach, which date back to 1938. In 1955 there was a disastrous 52-day strike among the . employees of the Capital Transit Co. and because of the disruption of public transport created by the situation,. the district's chartering authorities cancelled the company's franchise to operate and stipulated that its assets had to be sold within a year.

These assets were purchased by what is now the D.C. Transit System, Inc., which started to operate .under that name on August 15, 1956. At that time five White buses had. already been fitted with Leyland engines and the wisdom of this move was soon realized by the new board, as within two months the Leyrand conversion programme was resumed. At present two buses per week are being converted in the system's own workshop, the complete programme being scheduled for completion• early next year.

Conversion of 11:949 Midas

The White buses which are being converted were purchased in 1949 and are 35-ft. long underfloor-engined designs, the original power units being 24-AK 12-eylinderecl horizontally opposed 11.5-litre petrol engines with a gross output of 210 b.h.p. These engines were used in conjunction with White Hydro-Torque torque converters. The buses have 44 seats, with standing room for 27 passengers, and unladen they weigh about 9 tons. As the engines are changed, these buses are being given complete overhauls and modernized inside and out, including a new livery.

After the first of these had been in service five or six years, the engines became due for complete overhaul or even replacement. Meanwhile, White's had ceased to manufacture buses and the 24-AK engine was out of production. Some alternative unit had to be found to replace the engines which were to be cannibalized to keep the remaining vehicles of that type on the road, and it was decided to turn to oil.

After careful investigation the Leyland engine was chosen as being the most suitable, in that its power-toshape ratio closely matched that of the White. The five vehicles originally converted two years ago have already done over 100,000 miles without the need for major overhauls.

Mr. A. E. Savage, who is director of the mechanical department, told me that it was too soon yet to tell how the Leyland engines compared with the American units for life, but he hoped to obtain much longer mileages between overhauls. When fully run-in, the Leylandengined buses average 6.3 m.p.g., compared with the 3 m.p.g. returned by the petrol-engined White; and the 5.5 m.p.g. averaged with the Cummins oil-engined White, vehicles_

Fageol supply the Leyland engines for these conversions; complete with all moult: ings, new bell-housings and other non-standard fittings. Certain modifications are made to the engines, including the removal of the oil-filler necks from the sump, to the valve cover, so as to be on the right-hand side: Changes are also made to the auxiliary drives, the dynamo and air compressor being driven from a transposing box ahead of the engine, from which also is driven the fan jack-shaft.

This jack-shaft passes to the rear of the bus as all these White under-floor-engined designs have rearmounted radiators. A.C. generators, driven through a : 3 step-up, are fitted to all buses to give high output at low engine speeds.

Modifications are also made to the transmission. In the original version this consisted of a two-speed gear behind the torque converter, whilst the standard axle ratio was 5.57 to 1. Because the Leyland engine is governed at 2,100 r.p.m., as opposed to the 2,600 r.p.m., maximum speed of the White unit, the two-speed auxiliary gear is locked in its upper ratio (1 to 1) and a 6.67 to I rear-axle ratio has been adopted. This Tower axle ratio gives satisfactory performance on hills of up to 1 in 10, whilst the acceleration of the oilengined buses is almost as good as that of the st petrol-engined vehicles, and is quite sufficient for normal city operation.

• One disadvantage, however, is that the maximum speed of the Leyland-White is only 42 m.p.h., compared with nearly 60 m.p.h. of the original buses. This is no hardship when running in the city, but outside the city limits, where speeds of up to 60 m.p.h. are permitted, • the oilers are at a serious disadvantage.

Wisely, Mr. Savage is reluctant to raise the governor setting of the Leyland engine without knowledge of the maximum speeds at which such units have been run, and would welcome information from operators.

Of the other buses in the fleet little need be said: all are standard American designs, most of which have rear engines, and they range in capacity (including standing passengers) from 41 to 82. A significant change in unladen weight is evidenced in the fleet: for example, a 1940 White 41-passenger bus turned the scales unladen at just over 8.4 tons, whereas a 1953 G.M.C., with a total passenger capacity of 48, weighs only 4.7 tons.

Of the 508 trams still in service, 488 are of the P.C.C. (Presidents' Conference Cars) type. The design was initiated in 1937 as a result of a conference held by all the presidents of passenger-transport undertakings in the North American Continent, at which the "ideal modern tram" was formulated. These trams are still modern in conception and their specification includes rubbermounted wheel rims, sirnilar to those employed at Blackpool, which much reduce noise.

Most of these trams were built by the St. Louis Car Co. The Congress Board of Commissioners would like to see them replaced with buses by 1964, although D.C.

Transit are reluctant to do so. The trams and the track are still in good condition and the company believe that such a large fixed investment should not be abandoned before becoming uneconomical. In this view they are supported by the public. "

The area covered by D.C. Transit is principally administrative and residential and, although generally fairly flat, there are hills of up to I in 10. The main bus-traffic flows are from the residential areas to the north of the Potomac River—which extend into Maryland—to what is known as the "Federal Triangle," which is where the main 'Government offices are concen trated.

Seventy-five bask daily routes supplemented by 64 additional rush-hour services and 14 all-night (or "-owl ") services are worked by the buses. The daily round-trip mileage of the basic services totals 744.92; the figure for the peak-hour services is 773.36 and for the "owls " 171.11. In addition, a school service with a round-trip mileage of 13.3 is operated daily.

The shortest bus route is known as the Rosslyn Shuttle, which runs between Rosslyn and Georgetown, a round-trip of 2.09 miles, covering 1.27 miles of street. The longest route is the D4 Glover Park-Trinidad, with a round-trip mileage of 2015,. the street mileage being 11.71.

The longest " owl " service is the Tenleytown-Pennsylvania Avenue run (10 miles return), 0.22 mile of which is in the State of Maryland. Service frequency varies from a minute on certain rush-hour routes to an hour on suburban routes at off-peak periods.

All schedules are geared essentially to the office hours of the various Government departments, although slight progress has been made in staggering to spread the peak loadings. The morning peak occurs between 7 a.m. and 8.30 a.m., whilst the evening peak, which starts at 4 p.m., finishes at 6 p.m., after which there is little traffic in the centre of the town.

Favourable Topography

The topography of the district presents few difficulties to successful bus operation, other than the large park, Rock Creek, which divides the north-western section of the area.

There are five bridges across the Potomac River, but only one bus service crosses it. This is the K2 rush-hour route, which penetrates half a mile into Virginia. However, during peaks, large traffic jams of private cars frequently cause disruption of services on the approach roads to the bridges.

Apart from private motorists, taxi services, which are extremely numerous and cheap, are keen competitors of the buses. As a matter of course, many visitors to the city take a taxi rather than a bus, although to do so may be no quicker.

The sharp distinction between peak and off-peak requirements is a sore point with . many American bus operators. As in the case of Washington, it is accent-uated by the trend towards decentralization of the larger shops, which are moving to outlying areas to attract trade by saving potential customers the bother of coming

into the centre of the city. . •

20-cent Flat Fare The basic flat fare is 20 cents (1s.. 6d.), this being charged for any distance in the same general 'direction, with unlimited transfer within 1--1, hours of the initial purchase of the ticket. Tokens may be used instead of coins, these being sold by the company at five for -95 cents, whilst even better valuefor money is given by the weekly permits, .which are sold for a dollar and entitle purchasers to unlimited journeys for 10 cents each.

The standard fare for schoolchildren is 71 cents per journey, but as there is no -I-cent piece, tickets must be sold in twos. Policemen and firemen, when in uniform, are allowed free travel on any of the buses and all company employees have free passes.

As is general throughout the United States, all the Washington buses are one-man operated and employ the pay-as-you-enter system. Tickets are issued manually by the driver, transfer tickets being hand-punched or tarn, And money is collected in Cleveland " locked-box " receptacles, in which the coins fall into a box which can be cleared only at the depots.

D.C. Transit employ 1,906 drivers, all of whom are qualified to drive either trams or buses and are frequently interchanged between the two types of vehicle.

The current hourly rate for drivers with more than 12 months' service is $2.17 (16s. 3d.), and according to the published agreement between the D.C. Transit System and the Amalgamated Association of Street, Electric Railway and Motor Coach Employees of America, rates have been fixed until December 4, 1959, by which time drivers will be paid at the rate of $2.27 (17s.) per hour.

A first-class mechanic at present receives $2.30 (17s. 3d.) per hour and, under the agreement, this increases to $2.40 (18s.) in December, 1959.

Conditions relating to retirement pensions, sick-pay and welfare facilities are rigidly laid down in the union agreement. The pension scheme is contributory and offers varying monthly payments for life up to a maximum of $80..

Fleet Accommodation

There are six bits garages and six "streetcar houses in the district. In addition; there is a bus overhaul shop and a tram overhaul shop, a common paintshop being shared by them. The garages are permitted to do only such work as servicing, cleaning, minor repairs, unit replacements and inspections.

Basic servicing at these garages is. conducted by an evening shift of fitters, which starts when the evening rush-hour vehicles return to the garage. -Buses' arrive at the rate of one every two minutes and they are put into a large overflow park.

• They are refuelled in an interesting manner. As each vehicle is drawn up to the pump its left-hand wheels are lifted on .a small ramp which tilts. the bus and provides a small air pocket in the tank. This prevents completely filling the tanks and eliminates the possibility of fuel

wastage caused by expansion overnight.

Engine oil-filler orifices, which are close to the fuel fillers, have a maximum internal diameter. of 15/16 in., whereas the outside diameter of the fuel-pump mwles is 1 in.. This arrangemerit precludes the possibility of accidentally filling the engine crankcase with fuel.

After oil levels and the hub-odometer readings have been checked, each bus is driven over a service pit, where mechanics look for leaks, broken springs, faulty tyre § and loose accessories. At the same time, the brake slack adjusters are taken up and air tanks are drained.

Automatic Washing Each bus next passes through the automatic washing machine. Approximately 85 per cent. of all buses are serviced .after the evening peak, the remain-der being handled during the day.

An extensive inspection is given to each petrolengined bus every 6,000 miles, and each oiler every 8,000 miles, the buses first having been cleaned inside and out.

Several years ago it was common practice to renew all running units at a specific mileage determined by averaging the mileages at which earlier inspections had revealed that their useful life was finished. Nowadays, units are replaced according to their condition, it having been found that components were frequently replaced when not worn out.

All major repairs to buses are carried out at the main maintenance shop, vehicles being called in as their conditions demand it. Any bus entering the shop has all the units Which are scheduled to be changed, removed, dismantled and reconditioned in the workshops themselves, Indeed, the only bus maintenance work which not carried out at the shop is the rebuilding and repairing of springs, fuel tanks and batteries. The department is extremely well-equipped for all other tasks, and, although somewhat cramped because of its derivation from a tram shop, its layout makes the best of the space available.