The SEARCH for SUSPENSION

Page 34

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

FFICIENCY

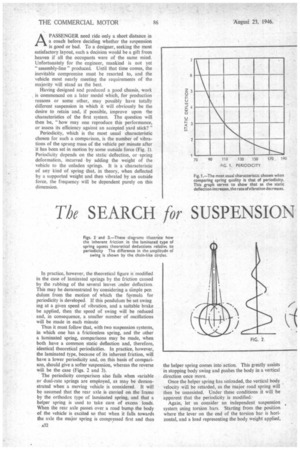

In practice, however, the theoretical figure is modified in the case of laminated springs by the friction caused by the rubbing of the several leaves .ander deflection. This may be demonstrated by considering a simple pen dulum from the motion of which the formula for periodicity is developed If this pendulum be set swing ing at a given speed of vibration, and a suitable brake be applied, then the speed of swing will be reduced and, in consequence, a smaller number of oscillations will be made in each minute Thus it must follow that, with two suspension systems, in which one has a frictionless spring, and the other a laminated spring, comparisons may be made, when both have a common static deflection and, therefore, identical theoretical periodicities. In practice, however, the laminated type, because of its inherent friction, will have a lower periodicity and, on this basis of comparison, should give a softer suspension, whereas the reverse will be the case (Figs. 2 and 3).

The periodicity comparison also fails when variable or dual-rate springs are employed, as may be demonstrated when a moving vehicle is considered. It will be assumed that the rear axle is carried on the frame by the orthodox type of laminated spring, and that a helper spring is used to take care of excess loads. When the rear axle passe § over a road bump the body of the vehicle is excited so that when it falls towards the axle the major spring is compressed first and then the helper spring comes into action. This greatly assists in stopping body swing and pushes the body in a vertical direction once more.

Once the helper spring has unloaded, the vertical body velocity will be retarded, as the Major road spring will then be unassisted. Under these conditions it will be apparent that the periodicity is modified.

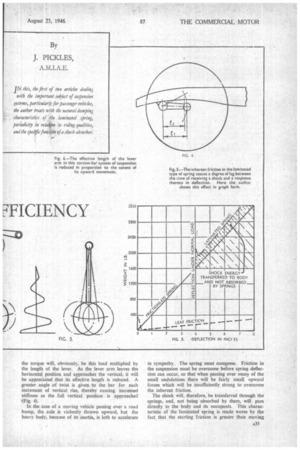

Again, let us consider an independent suspension system using torsion bars. Starting from the position where the lever on the end of the torsion bar is horizontal, and a load representing the body weight applied,

the torque will, obviously, be this load multiplied by the length of the lever. As the lever arm leaves the horizontal position and approaches the vertical, it will be appreciated that its effective length is reduced. A greater angle of twist is given to the bar for each increment of vertical rise, thereby causing increased stiffness as the full vertical position is approached (Fig. 4).

In the case of a moving vehicle passing over a road bump, the axle is violently thrown upward, but the heavy body, because of its inertia, is loth to accelerate in sympathy. The spring must compress. Friction in the suspension must be overcome before spring deflection can occur, so that when passing over many of the small undulations there will be fairly small upward forces which will be insufficiently strong to overcome the inherent friction.

The shock will, therefore, be transferred through the springs, and, not being absorbed by them, will pass directly to the body and its occupants. This characteristic of the laminated spring is made worse by the fact, that the starting friction is greater than moving

friction, and every time the spring ceases to move an unduly high breakaway force must be applied. (Fig. 5.) Ample lubrication helps to overcome this difficulty, but this is a factor for which there can be no calculation, as the degree of mitigation from this source is dependent on the efficiency of the maintenance staff. Even at best, mud is liable to enter and resist the lubricant in its work.

The self-damping which goes with leaf friction is invariably claimed as advantageous, and so it undoubtedly is for goods vehicles where comfort is secondary to simplicity. For passenger vehicles, however, to make the best of a fault is not good enough, when scientific damping is readily available. With the object of reducing interleaf friction, many patents have been filed and devices made.

Interleaving materials such as bronze, fabric, impregnated paper, and the like, have all been used at one time or another. Oil reservoirs at the leaf tips, and inserted rollers, have been introduced with the same object, and a recent American vehicle has featured leaves which were widely spaced, so that contact is made only at the leaf tips.

Even certain of the new independent-suspension systems may be criticized, as multitudinous bearings cause friction not much less than in the older and more simple systems.

Hydraulic Shock-absorbers Improve Riding

Hydraulic shock-absorbers are a vast improvement when used in conjunction with a low-friction suspension, as the valve resistances may be so proportioned that, on impact, the shock-absorber applies but little resistance, whereas, on the rebound, a greatly increased damping effect is applied. High road speeds impose correspondingly rapid axle rising, which may cause dangerous pitching, but with increased speed the hydraulic units raise their resistance.

The term shock-absorber has caused some confusion in that it attributes powers to the mechanism which it does not possess. if, for instance, it were of very great stiffness, the road spring would not be permitted to deflect, and the greater part of the road shock would be transmitted to the body.

In fact, it is the purpose of these mechanisms to damp out the vibrations which would continue indefinitely after an initial disturbing force, so that, by reducing the resistance on meeting a bump, the damping may be applied on rebound, and yet not cause the transmission of undue road shock to the passengers.

Although periodicity is not a suitable medium for comparison, an ideal suspension must be designed, so that the vibration frequency is most suited to the comfort of the occupants.

The ideal value is, of course, impossible to determine for every individual, and the usual compromise must be sought. Several attempts have been made to base

a suitable frequency on known characteristics of the human body. The heart-beats in a normal healthy adult average some 72 per minute and it is sometimes claimed that to be vibrated at a similar speed causes no unpleasant effect. Similarly, the number of steps taken per minute, in average walking, may be taken as the criterion.

In fact, frequencies of between 110 and 70 are acceptable, and the final choice is usually dictated by such considerations as clearance between axle and frame, and that between ground and side members on the rebound. Roll must be maintained within safe limits, and a premium is, therefore, placed on the deflection.

Very soft suspension systems react in a similar manner to a ship at sea and can have unfortunate effects on persons riding in a vehicle so sprung, but deflsctions of an order great enough to cause trouble of this nature can rarely be used on a passenger-service vehicle. Over-hardness is more usual, particularly when running lightly loaded, and without the aid of complicated and advanced devices it is difficult to see how improvement can be effected.

Adapting Motorcycle Practice to " Commercials " A device which has been adopted for motorcycle use might well be employed to advantage by vehicle designers. I refer to the hydraulic type of front-fork assembly in which there is the equivalent of a cylinder and piston. A large quantity of oil is contained in the cylinder portion, so that when piston movement occurs the oil is transferred from one side to the other via calibrated apertures in the skirt and, finally, a large hole in the crown.

The restriction imposed by the oil passing through the skirt apertures provides the necessary damping to limit the vibrations occurring after an initial shock. In traversing a large bump the piston is driven upward, and a conical extension passes into the hole in the piston crown, so that the greater the amount of entry the smaller the remaining annular space. Finally, the path for the fluid is completely shut off and, when this occurs, the upward motion of the wheel is arrested by an hydraulic cushion. A process having a similar result occurs on the rebound.

A suspension unit based on this principle would have ideal characteristics for a high-speed passenger vehicle. Although the mere provision of fixed holes for damping would be Unsuitable for a highly developed suspension system as the resistance imposed is necessarily equal on bump and rebound, the provision of valves to give a reduced resistance during bump could be easily arranged. A " soft " ride would be obtained when traversing small undulations, and there would be increased resistance to take care of abnormal conditions without a heavy impact as the axle reached the end of its travel.

(To be concluded.)