INCREASING THE UTILIT

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

17 OF PLATFORM LORRIES APLATFORM lorry for carrying a load of crates of bottled beer or mineral waters, has a front and a back board, which are held together at the top by a centre ridge pole. Above this pole is a longitudinal board for writing display. This type of body may be modified in various ways to increase its utility and yet remain essentially a platform body, with its advantage of easy access.

Although a centre ridge pole will support a waterproof sheet, this Method of protecting the load is improved by the addition of side ridge poles. If one or two intermediate side pillars be introduced these may be continued across the top as hoopsticks, so that a roof framework is available. This will give not only full support to the tarpaulin, but s30 also facilitate its placing in position, or its removal.

A name board immediately above the centre ridge pole prevents the close fitting of the waterproof sheet, but if there be side standards and hoopsticks, the central board may be replaced by one on each side.

Publicity on Platform Lorries.

Space for writing display is important with a platform lorry, because, with the exception of the back, there are usually few places available for this purpose. For this reason the back is close-boarded, although this form of construction is seldom essential, even when the load does not consist -of crates. Weight is saved by reducing the number of boards and retaining the intermediate pillars. Two or three wide boards will still leave room for an effective display of writing. If the back board be regarded as a dust shield, the spaces between the boards may be filled with an aluminium panel.

The design of the back of the lorry may be varied by introducing a tailboard. This may be a high one, reaching to the roof line, so that there is as much area for writing display as with a back board, or it may be of normal dimensions and the load above the tailboard is protected by a hinged rod or leathercovered chain.

Instead of the skeleton roof, previously described, supporting a loose sheet, the framework may have a fixed cover of similar material, or the roof may be boarded.

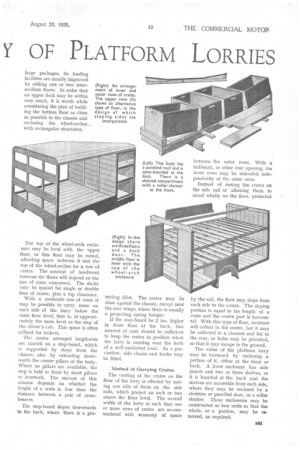

If a platform lorry does not carry large packages, its loading facilities are usually improved by adding one or two intermediate floors. In order that an upper deck may be within easy reach, it is worth while considering the plan of building the bottom floor as close as possible to the chassis and enclosing the wheel-arches with rectangular structures.

The top of the wheel-arch enclosure may be level with the upper floor, or this floor may be raised, affording space between it and the top of the wheel-arches for a row of crates. The amount of headroom between the floors will depend on the size of crate concerned. The decks may be spaced for single or double tiers of crates, plus a top clearance.

With a moderate size of crate it may be possible to carry some on each side of the lorry below the main floor level, that is, at approximately the same level as the step of the driver's cab. This space is often utilized for lockers.

The crates arranged lengthwise are carried on a step-board, which is supported by stays from the chassis, also by extending downwards the corner pillars of the body. Where no pillars are available, the step is held in front by short pillars or ironwork. The success of this scheme depends on whether the length of a crate is less than the distance between a pair of crossbearers.

The step-board slopes downwards to the back, where there is a pro

tecting fillet. The crates may lie close against the chassis, except near the rear wings, where there is usually a projecting spring hanger.

If the step-board be 2 ins, higher in front than at the back, this amount of cant should be sufficient to keep the crates in position when the lorry is running near the kerb of a well-cambered road. As a precaution, side chains and hooks may be fitted.

Method of Carrying Crates.

The canting of the crates on the floor of the lorry is effected by resting one side of them on the side rails, which project an inch or two above the floor level. The overall width of the lorry is such that one or more rows of crates are accommodated with economy of space

between the outer rows. With a tailboard, or other rear opening, the inner rows may be unloaded independently of the outer ones.

Instead of resting the crates on the side rail or allowing them to stand wholly on the floor, protected

by the rail, the floor may slope from each side to the centre. The sloping portion is equal to the length of a crate and the centre part is horizontal. With this type of floor, moisture will collect in the centre, but it may be collected in a channel and led to the rear, or holes may be provided, so that it may escape to the ground.

The value of the platform lorry may be increased by enclosing a portion of it, either at the front or back. A front enclosure has side panels and two or three shelves, or it is boarded at the hack and the shelves are accessible from each side, where they may be enclosed by a skeleton or panelled door, or a roller shutter. These enclosures may be constructed as box units so that the whole, or a portion, may be removed, as required.