A VARIABLE GEAR WITH HYDRAULIC CLUTCH.

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

A Résumé of Recently Published .Patent Specifications.

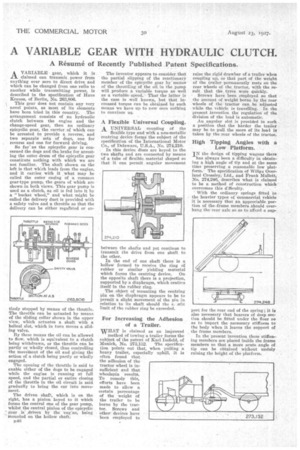

A VARIABLE gear, which it is 1-1 claimed can transmit power from anything over zero to direct drive. and which can be changed from one ratio to another while transmitting power, is described in the specification of Hans Krause, of Berlin, No. 263,806.

This gear does not contain any very navel points, as most of its elements have been tried in this country. The arrangement consists of an hydraulic clutch between the engine and the change-speed gear, then an ordinary epicyclic gear, the carrier of which can be arrested to provide a reverse, and two separate sets of dogs, one for reverse and one for forward driving.

So far as the epicyclic gear is concerned the dogs and the brake for arresting the outer-drum of the epicyclic gear constitute nothing with which we are not familiar. The shaft shown on the left is that which leads from the engine, and it carries with it what may be called the outer casing of a common gear-type pump, the gears of which are shown in both views. This gear pump is used as a clutch, as oil is fed into it by a " bucket wheel," and what might be called the delivery duct is provided with a safety valve and a throttle so that the delivery can be either regurated or en tirely stopped by means of the throttle. The throttle can be actuated by means of the sliding collar shown in the upper view, which actuates a shaft with a helical slot, which in turn moves a sliding valve.

By these means the oil can be allowed to flow, which is equivalent to a 'clutch being withdrawn, or the throttle can be partly or wholly closed, thus controlling the movement of the oil and giving the action of a clutch being partly or wholly engaged.

The opening of the throttle is said to enable either of the dogs to be engaged while the engine is running at full speed, and the partial or entire closing of the throttle in the oil circuit is said gradually to bring the car into movement.

The driven shaft, which is on the right, has a pinion keyed to it which forms the central one of the gear pump, whilst the central pinion of the epicyclic .` gear is ,driven FY the etigitie, being Mounted on the hollow shaft.

n4f1

The inventor appears to consider that the partial slipping of the reactionary member of the epicyclic gear by' means of the throttling of the oil, in the pump will produce a variable torque as well as a variable speed. That the latter is the case is well known, but that increased torque can -be obtained by such means we have up to now seen nothing to convince us.

A Flexible Universal Coupling.

A UNIVERSAL coupling of the flexible type and with a non-metallic centring device forms the subject of the specification of the International Motor Co., of Delaware, USA., No. 274,210. In this device discs are keyed to the two shafts and are connected by means of a tube of flexible material shaped so that it can permit angular movement

between the shafts and yet continue to transmit the drive from one shaft to the other.

In the end of one shaft there is a hollow formed to receive the ring Of rubber or similar yielding material which forms the centring device. On the opposite shaft there is a projection, supported by a diaphragm, which centres itself in the rubber ring.

The object of mounting the centring pin on the diaphragm appears to be to permit a slight movement of the pin in relation to its shaft should the e, .stic limit of the rubber ring be exceeded.

For Increasing the Adhesion of a Trailer.

WHAT is claimed as an improved method of towing a trailer forms the subject of the patent of Karl Imfield, of

Munich, No. 273,132. The specification points out that, when pulling a heavy trailer, especially uphill, it is often found that the adhesion of the tractor wheel is insufficient and that wheelspin results. To remedy this, efforts have been made to allow a certain percentage of the weight of the trailer to be borne by the tractor. Screws and Other' device's have been employed to raise the rigid drawbar of a trailer when coupling up, so that part of the weight of the trailer permanently rests on the rear, Wheels of the tractor, withthe result that the tyres wore quickly.

• Screws have been employed so that the 'amount of Weight borne by the rear wheels of the tractor can be adjusted while the vehicle is travelling. In the present invention the regulation of the division of the load is automatic.

An angular slot is provided in such a position that the harder the trailer may be to pull the more of its load is taken by the rear wheels of the tractor.

High Tipping Angles with a • Low Platform.

IN the design of tipping wagons there has always been a difficulty in obtaining it high angle of tin and at the same time preserving a reasonable low platform. The specification of Willys Overland Crossley; Ltd„ and Frank Mallett, Nb. 274,246, describes what is claimed to be a method of construction which overcomes this d'fficulty.

' With the ordinary springs fitted to the heavier types of commercial vehicle it is necessary that an appreciable portion of the frame members should overhang the rear axle so as to afford a sup

port for the rear end of the spring; it is also necessary that bearers of deep section should be fitted under the floor so as to impart the necessary stiffness to the body when it leaves the support of the frame members.

In the present invention these stiffening members are placed inside the frame members so that a More acute angle of tip can be obtained without unduly raising the height of the platform.