CUTTING DOWN CLEANING COSTS.

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

An Hydraulic Washing Plant that Saves Time and Money.

TF owners who have not already

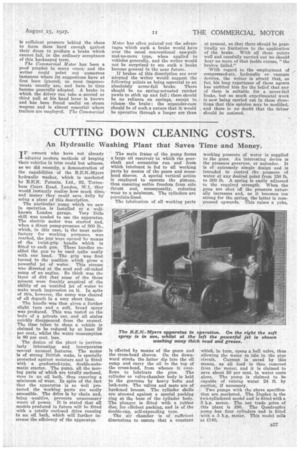

adopted modern methods of keeping their vehicles in trim could but witness, as we did recently, a demonstration of the capabilities of the B.E.N.-Myers hydraulic washer, which is marketed by B.E.N. Patents, Ltd., 92, Tottenham Court Road, London, WA, they would instantly realize how much timer and money they could save daily by using a plant of this description.

The particular pump which we saw in operation is installed at a wellknown London garage. Very little skill was needed to use the apparatus. The electric motor was started and, when a direct pump-pressure of 200 lb., which, in this case, is the most satisfactory for working purposes, was reached, the jets were opened by means of the twist-grip handle which is fitted to each gun. These handles enabled the gun to be used quite easily with one hand. The grip was first turned to the position which gives a powerful jet of water. This stream was directed at the mud and oil-caked sump of an engine. So thick was the layer of dirt that some of the those present were frankly sceptical of the ability of an unaided jet of water to make much impression on it. In spite of this, however, the sump was cleared of all deposit in a very short time.

The handle was then given a further slight turn and a soft, broad spray was produced. This was tested on the body of a private car, and all stains quickly disappeared from the enamel. The time taken to clean a vehicle is claimed to be reduced by at least 50 per cent., whilst the water consumption is 90 per cent. less.

The design of the plant is particularly interesting and incorporates several unusual features. The motor Is of strong British make, is specially protected against moisture and is fitted with a graduated-type, double-automatic starter. The pump, all the moving parts of which are totally enclosed, runs in an oil bath, thus ensuring a minimum of wear. In spite of the fact that the apparatus is so well protected the working parts are easily accessible. The drive is by chain and, being -positive, prevents unnecessary waste of power. It is stated that all models produced in future will be fitted with a totally enclosed drive running in an oil bath, which will further increase the efficiency of the apparatus. The main frame of the pump forms a large oil reservoir in which the gearshaft and eccentrics run and from which lubricant is fed to all working parts by means of the gears and crosshead sleeves. A special vertical action is employed to operate the pistons, thus ensuring entire freedom from side thrust and, consequently, reducing wear to a minimum. The cylinders are porcelain-lined.

The lubrication of all working parts

is effected by means of the gears and the cross-head sleeves. On the downward stroke the latter dip into the oil sump and carry the oil to the top of the cross-bead, from whence it overflows to lubricate the pins. The cylinder or valve-chamber body is held to the gearcase by heavy bolts and lock-nuts. The valves and seats are of hardened bronze. The cylinder shells are screwed against a special packing ring at the base of the cylinder body. The plunger is fitted with a rubber disc, for efficient packing, and is of the double-cap, self-expanding type.

The air chamber is of sufficient dimensions to ensure that a constant

working pressure of water is supplied to the guns. An interesting device is the pressure governor, or unloader. It is of extremely simple design and is intended to control the pressure of water at any desired point from 150 lb. to 300 lb. A spring is easily adjusted to the required strength. When the guns are shut off the pressure naturally increases and, as it becomes too strong for the spring, the latter is corn pressed upwards. This raises a yoke, which, in turn, opens a ball valve, thus allowing the water to idle in the pipe circuit. Current is saved by this means, as all load is then removed from the motor, and it is claimed to save about 50 per cent. in water costs alone. The pump is claimed to be capable of raising water 24 ft. by suction, if necessary.

Two pumps with the above specification are marketed. The Duplex is the two-cylindered model and is fitted with a 3 h.p. motor. The net trade price of this plant is £90. The Quadruplex pump has four cylinders and is fitted with a 5 h.p. motor. This model sells at £140.