AN INDUSTRIAL TRUCK

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

from a

Famous Motorcycle Factory

WHEREVER the British motorcycle is known the name of Douglas Motorsi Ltd., is a household word, and the debut of this concern into the commercial-vehicle market is, therefore, all the more interesting.

The vehicle, which has been produced at the Kingswood factory, Bristol, is a three-wheeled industrial truck, the front wheel of which both drives and steers. It can carry

load of about 1 ton and any type of body can be fitted. In addition, the haulage of trailers is another task of which it is capable. The rear of the chassis can be sprung or unsprung, as the customer desires. The single-gear ratio also can be varied according to whether the machine be made to suit work in a factory, a quarry or dockyard. In the present instance our description pertains to the unsprung model used in the maker's works.

Handiness in Confined Spaces.

An essential feature of such a vehicle is its power to manceuvre in very restricted spaces; the Douglas truck fully complies with all requirements in this direction. Its wheelbase is 6 ft. 8 ins, and it can turn around and around in a circle of that radius, the inner rear wheel being the pivot point. Probably the most interesting feature is the fact that, although no reverse gear is provided, the machine can travel backwards by the simple expedient of turning the front driving wheel through 180 degrees by means of the steering wheel. As the drive from the engine to the front wheel is always in the same direction, the vehiclJ will run forwards or backwards eccording to Whether the front wheel be rotating in an anti-clockwise or clockwise direction, viewed from the near side.

The Douglas industrial truck will be marketed at 1120 and should find a ready sale, as it is sturdily constructed and exceedingly simple to work ; there arc no gears to change and a labourer can be trained in a few hours to handle the truck with safety. One of the first models made is running about the Douglas works and, we are

C30

informed, is Consuming one gallon of petrol per 12-hours. work.

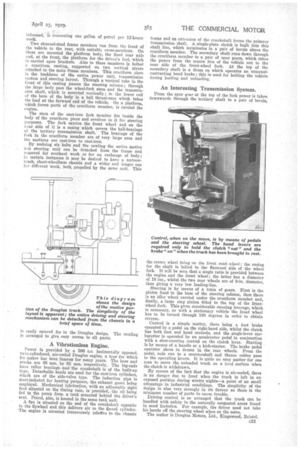

Two channel-steel frame members run from the front of the vehicle to the rear, with suitable cross-members. On these are mounted the platform body, the fixed rear axle and, at the front, the platform for the driver's feet, which is carried upon brackets. Also to these members is bolted a cruciform casting, supported on two vertical struts attached to the main frame members. This cruciform piece is the backbone of the entire power unit, transmission system and steering layout. Through a vertical tube in the front of this casting passes the steering column ; through the large body pass the wheel-fork stem and the transmission shaft, which is mounted vertically; in the lower end of the bore of the body is a ball thrust-race which takes the load at the forward end of the vehicle. On a platform, which forms parts of the cruciform member, is carried the engine.

The stem of the cast-iron fork member fits inside the body of the cruciform piece and revolves in it for steering purposes. The fork carries the front wheel and on the near side of it is a casing which covers the ball-bearings of the tertiary transmission shaft. The bearings of the fork in the cruciform member are of very large area and the surfaces are cast-iron to cast-iron.

By undoing six bolts and the cowling the entire motive and steering unit can be detached from the frame and removed for overhaul work or for an exchange of body ; in certain instances it may be desired to have a narrowtrack, short-wheelbase chassis and a wider and longer one for different work, both, propelled by the same unit. This is easily catered for in the Douglas design. The cowling is arranged to give easy access to all parts.

A VibrationIess Engine.

Power is provided by a 596 c.c. horizontally opposed, twin-eylinclered, air-cooled Douglas engine, a type for which its maker has been famous for many years. The bore and stroke are 68 ram. by 82 ram. respectively. The big-ends have roller bearings and the crankshaft is of the built-up tape. Detachable heads are used for the cast-iron cylinders, -which are of the side-valve type. The induction pipe is steel-jacketed for heating purposes, the exhaust gases being employed. Mechanical lubrication, with an adjustable sight feed situated on the timing ease, is provided, the oil being fed to the pump from a tank mounted behind the driver's seat. Petrol, also, is housed in the same tank unit.

A fan is situated on the end of the crankshaft opposite to the flywheel and this delivers air to the finned cylinder. The engine is mounted transversely relative to the chassis frame and an extension of the crankshaft forms the primary transmission shaft. A single-plate clutch is built into this shaft line, which terminates in a pair of bevels above the cruciform member. The secondary shaft runs down through the cruciform member to a pair of spur gears, which takes the power from the centre line of the vehicle out to the near side of the front-wheel fork. At the top of the secondary shaft is a drum on which operates an externalcontracting band brake; this is used for holding the vehicle during loading and unloading.

An Interesting Transmission System.

From the spur gear at the top of the fork power is taken downwards through the tertiary shaft to a pair of bevels,

the crown wheel being on the front road wheel ; the casing for the shaft is bolted to the flattened side of the wheel fork. It will be seen that a single ratio is provided between the engine and the front wheel; the latter has a diameter of 18 ins., whilst the two rear wheels are of 9-in, diameter, thus giving a very low loading-line.

Steering is by means of a train of gears. First is the pinion fixed to the base of the steering column, then there is an idler wheel carried under the cruciform member and, finally, a large ring pinion fitted to the top of the frontwheel fork. This gives considerable steering leverage, which is necessary, as with a stationary vehicle the front wheel has to be turned through 180 degrees in order to obtain reverse.

Control is a simple matter, there being a foot brake operated by a pedal on the right-hand side, whilst the clutch has both foot and hand controls, and the single-lever carburetter is operated by an accelerator pedal in conjunction with a slow-running control on the clutch lever. Starting is by means of a handle or a kick-starter. The brake pedal operates shoes in drums in the rear wheels. From the pedal, rods run to a countershaft and thence cables pass to the operating levers. It is quite an easy matter for one man to move the unloaded truck on a level surface when the clutch is withdrawn.

By reason of the fact that the engine is air-cooled, there is no danger due to frost when the truck is left in an exposed position during winter nights—a point of no small advantage in industrial conditions. The simplicity of the design is also very strongly in its favour as there is the minimum number of parts to cause trouble.

Driving control is so arranged that the truck can be handled with safety in the naturally congested areas found in most factories. For example, the driver need not take his hands off the steering wheel when on the move.

The maker is Douglas Motors, Ltd., Kingswoocl, Bristol. c31