Tankclean . taking the strain

Page 49

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

• Why go to the expense of installing your own vehicle washing system when we will do it for you? This is the question posed by Tankclean, the Harrogate-based subsidiary of the NFC's bulk-haulage company Tankfreight.

Tankclean, which specialises in cleaning the interiors of road tankers or containers, plans to establish plants for cleaning the exteriors of all types of commercial vehicles. In simple terms, the system is very similar to the "drivein" concept familiar to any car driver.

Pat Healy, Tankclean's commercial manager, outlined the scheme which it is in the process of implementing. "We hope to set up the first nationwide chain of livery wash outlets. They will be situated on the same sites as our current tank-cleaning facilities," he says.

"We currently have eight depots in the UK, and will be expanding this to 10 during 1989."

Tankclean is aiming to open two livery washes this year, the first in October at its Southampton site, and the second in November at Purfleet. The rest should begin vehicle washing in 1989.

Tankclean is already requested by some of its tank cleaning customers to clean the exterior of the vehicle as well, so the idea to make this a permanent service was an obvious extension. Natural ly, the bulk of the initial clients will be the tanker hauliers, but Healy is keen to attract all kinds of vehicles.

"We will be marketing the idea not only to tanker operators," he says, "but also to coach companies, to the municipals, to removals companies and to general haulage operators. Customers will be charged according to size of the vehicle, and we will be able to discuss creating accounts for major users."

Returning to the original question, Healy wonders whether companies really appreciate the true costs of operating vehicle washing equipment. Rather than merely considering the expenditure of purchasing the washer itself, he suggests that companies should think about the costs involved in administration, maintenance and breakdowns.

Another factor emphasised by Tankclean is the need to comply with the requirements of the local water authorities regarding the control of waste products from the cleaning process. "With the possible privatisation of the water authorities, the treatment or discharge of the wash water could well be viewed more critically," explains Healy.

Tankclean, it is claimed, is in an ideal position to comply with any new requirements because of its experience in dealing with the waste from tanker cleaning. An interesting problem was faced by Tankclean when it came to choosing the kind of washing equipment to install. For the scale of operation it had in mind, a gantry installation was obviously needed, but the decision between a brush system or a spray system was not so easy. The former provides the most effective cleaning in most circumstances, but is more expensive and has difficulty in copying with awkwardly shaped vehicles — it can also cause damage to vulnerable attachments. The former can handle irregularly shaped units, and is faster than conventional brush systems.

Tankclean eventually decided on a brushless set-up for the added flexibility it could provide. An attendant will be present at each washer, and any difficult areas to wash will be cleaned by hand to ensure a consistency of finish.

In describing its new service as a "livery wash", Tankclean is clearly aiming at the image-conscious operator. Market forces are undoubtedly causing more companies to take a serious look at vehicle washing, and with 1992 approaching, the presentation of the UK's trucks may well affect their competitiveness against Continental fleets. With its proposed network, Tankclean is offering operators of all sizes an alternative to do-it-yourself cleaning. spray systems, and also the more rare interior cleaners.

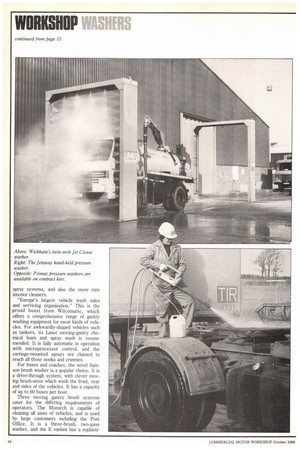

"Europe's largest vehicle wash sales and servicing organisation." This is the proud boast from Wilcomatic, which offers a comprehensive range of gantry washing equipment for most kinds of vehicles. For awkwardly-shaped vehicles such as tankers, its Laser moving-gantry chemical foam and spray wash is recommended. It is fully automatic in operation with microprocessor control, and the carriage-mounted sprays are claimed to reach all those nooks and crannies.

For buses and coaches, the novel Samson brush washer is a popular choice. It is a drive-through system, with clever moving brush-arms which wash the front, rear and sides of the vehicles. It has a capacity of up to 60 buses per hour.

Three moving gantry brush systems cater for the differing requirements of operators. The Monarch is capable of cleaning all sizes of vehicles, and is used by large customers including the Post Office. It is a three-brush, two-pass washer, and the E variant has a sophisti cated microprocessor controller. The Fleetwasher II and the Fleetmaster V and three and five-brush systems respectively, and are aimed primarily at the larger truck and bus fleet operators.

For chassis cleaning, Wilcotnatic offers two options, the fully-automated Superclean for chassis up to 18m long, and the lower-pressure Jetstream which can be used in conjunction with the regular exterior wash.

Perhaps unique is Wilcomatic's Jetclean — an automatic interior-washing system, suitable for all box van and container vehicles. A carriage-mounted spray system travels the length of the container, cleaning it quickly and effectively. As with all its products, Wilcomatic emphasises its Frozen Asset frost-protection system which uses heater tapes, a pumpheater and blow-down to clear the water lines in sub-zero weather.

Diversey, which offers a whole range of vehicle washing products, has chosen a fixed-arch spray system for its Fleetcleaner product. Able to cope with different shapes and sizes of commercial vehicles, the Fleetcleaner has electronic control and is constructed out of materials designed to minimise problemss from corrosion and chemical attack — the pipework to the chemical arch is made from plastic, for example.

Comprehensive choice With a comprehensive range of brush washers, the French-owned Neptune company has achieved success both on the Continent and in the UK. There are three different fixed systems (descriptively called "tunnel" washes by Neptune), and two moving-arch systems. Of the fixed alternatives, the Atlantic B is aimed at bus and coach operators, and features four vertical brushes with the option of an additional roof brush.

Large HGV fleet-owners will be interested in the Atlantic T, which is available with four or six brushes. The Barents is intended for heavy-duty industrial fleets, and is able to wash tankers. It can incorporate up to five different systems — a chemical arch, vertical brushes, a horizontal brush, a rinse arch and an underchassis wash.

The Beaufort B is Neptune's movingarch washer for the PSV market, and is available in twoor three-brush forms. The latter is a multi-programme version designed for larger, more diverse fleets.

The Beaufort T is a three-brush washer capable of coping with all sizes of commercial vehicles. All Neptune models are offered with a wide range of options, including wheel washers, chassis sprays and frost protection systems.

Another range of washes with a continental ingredient is the Tammermatic range, which is manufactured in Finland,

but which is also made under licence by the UK distributor, Technorizon. The Rainbow is a three-brush roll-over machine designed to wash all sizes of vehicles up to 4.9m high. Options include pre-wash systems, chassis washers, and four standard heights are available.

Tammermatic also produces a drivethrough range aimed particularly at bus and coach users. The XJ-400 series is an automatic unit with four brushes on separate swingframe assemblies, and the option of an extra top brush. The XJ-500 series has a different washing action, and can be ordered with two or four vertical brushes according to the operator's requirements. Again, a top brush is available as an option.

Ardrox F'yrene, which also supplies a large range of cleaning chemicals, concentrates on spray washers for its gantry system. Its fixed-arch model is a very simple twin-arch design, and is aimed to be a quick and simple method of cleaning all kinds of vehicles. Systems are installed to suit the needs of individual operators, and underbody washes and high-pressure lances can be added as extras. A similar tailor-made approach is employed with the moving-arch washer, and an automatic boom facility can be provided to give extra cleaning for the rear of vehicles.

Another firm to prefer spray washers is Wickham, and again a simple twin-arch approach is used. The Jet Clense uses oscillating high-pressure jets, and can clean vehicles of all shapes of up to 4.6m high and 2.9m wide. Proximity sensors are used to activate the sprays as the driver guides the vehicles through the arches. The Jet Wash 2 is very similar, but used fixed-angle jets.

Wickham also offers three types of underbody washes designed for unattended operation. The Hurricane and Monsoon use oscillating jets, with the latter being the heavy-duty model. The Tempest uses fixed jets, and along with the Hurricane can be fitted with both the arch cleaners.

Large fleet owners in the market for gantry systems will find plenty of manufacturers willing to discuss their requirements. In addition to those mentioned above, firms such as Smith Brothers & Webb and Esquire Kleindienst also supply systems. Not everyone can go to the expense of a gantry system, however. For the smaller operator, pressure washers can increase the speed and quality of vehicle cleaning, and are available at a reasonable cost. A cold-water washer will do the job for those on a tighter budget, while better results, particularly where grease and oil are present, can be obtained from the more expensive hotwater washers.

Daddy of the range One of the best established companies in the pressure washer field is Wickham. Daddy of its range is the Meteor, which is a steam cleaner as well as a hot or cold water washer. Running on paraffin, the Meteor is available in 90 bar (1,300psi) and 145 bar (2000psi) versions.

The Wickham Tornado is a cold-water washer, driven by electric motors or petrol and diesel engines, with output pressures ranging from 90 to 145 bar. A lightweight version called the Tornado 209 is also produced, and the electric-motor powered washer can be bought in 68 or 90 bar forms.

Warwick offers a full range of cleaners with a variety of power sources. The HX series are electric hot-water machines with outputs from 70 to 150 bar. The same pressure range is available in the electric CX series of cold-water washers. The CP100 is a petrol-engined 100 bar cold-water unit, and diesel-engined equivalent is the 150 bar CD150. The trailermounted TM160 rounds off the range, and is a 150 bar diesel-powered hot and cold washer.

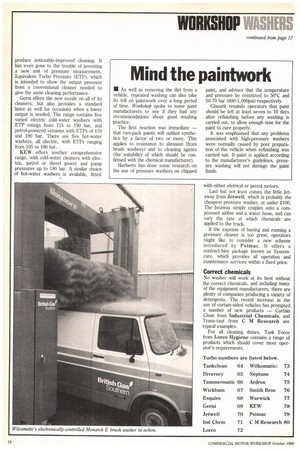

A company claiming to offer something new is Gerni. While using the name

Turbo is hardly original, Gerni says its new Turbo Laser nozzle is unique and can produce noticeably-improved cleaning. It has even gone to the trouble of inventing a new unit of pressure measurement, Equivalent Turbo Pressure (ETP), which is intended to show the output pressure from a conventional cleaner needed to give the same cleaning performance.

Gerni offers the new nozzle on all of its cleaners, but also provides a standard lance as well for occasions when a lower output is needed. The range contains five varied electric cold-water washers with ETP ratings from 115 to 190 bar, and petrol-powered versions with ETPs of 170 and 190 bar. There are five hot-water washers, all electric, with ETPs ranging from 105 to 190 bar.

KEW offers another comprehensive range, with cold-water cleaners with electric, petrol or diesel power and pump pressures up to 180 bar. A similar choice of hot-water washers is available, fitted with either eletrical or petrol motors.

Last but not least comes the little Jetaway from Jetwell, which is probably the cheapest pressure washer, at under 2100. The Jetaway simply couples onto a compressed airline and a water hose, and can vary the rate at which chemicals are applied to the truck.

If the expense of buying and running a pressure cleaner is too great, operators might like to consider a new scheme introduced by Psimac. It offers a contract-hire package known as Systemcare, which provides all operation and maintenance services within a fixed price.

Correct chemicals

No washer will work at its best without the correct chemicals, and including many of the equipment manufacturers, there are plenty of companies producing a variety of detergents. The recent increase in the use of curtain-sided vehicles has prompted a number of new products — Curtain Clean from Industrial Chemicals, and Trans-taut from C M Research are typical examples.

For all cleaning duties, Task Force from Lorco Hygiene contains a range of products which should cover most operator's requirements.