CENTRAL'S WAY AHEAD

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

Impending legislation will mean every truck leaving or entering the UK will be legally required to be weighed. Like other weighbridge manufacturers, Central Weighing is expecting a boom in sales.

• The Herald of Free Enterprise disaster alerted the authorities to a number of misdemeanours committed, knowingly or otherwise, by hauliers using ferries.

In our ferries issue (CM 25 February-2 March) we highlighted the problems of moving hazardous goods by RO-RO ferry, but truck weights have also attracted a lot of attention.

The Department of Transport has instigated legislation requiring that, by the middle of January 1989, every commercial vehicle leaving the country by RO-RO ferry should first be weighed. Further legislation, now in preparation, will require all commercial vehicles entering the UK by RO-RO to be check-weighed on first landing at British ports.

Not surprisingly, the weighbridge manufacturers are expecting a boom in the coming months. Informed estimates suggest that as many as 90 weighbridges, together worth around E4 million, will be installed at Britain's RO-RO ports.

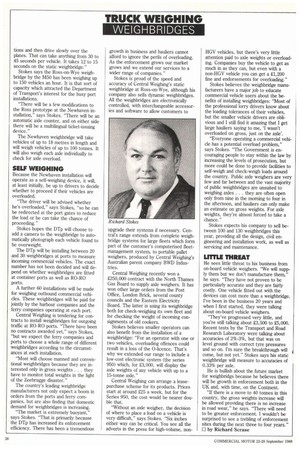

One of the first companies to benefit from this work is Central Weighing, a four-year-old firm based on the Hartlebury Trading Estate which also accommodates the TNT and Interlink parcels hubs.

Central's founder Richard Stokes says his company will be installing a weighbridge on behalf of the Department of Transport at the port of Newhaven in East Sussex. The system will be in opera

tion by the end of the year, weighing all incoming commercial vehicles as they clear customs,

SIMILAR SYSTEM

"Newhaven will be an unmanned selfweigh site," says Stokes. "The Department of Transport installed one of our static systems at Ross-on-Wye for close evaluation 18 months ago." A similar system will be installed at Newhaven.

"The advantage of static systems as against in-motion systems is their accuracy and speed," he says. "They're up to three times quicker. With in-motion systems, drivers have to stop, get instruc tions and then drive slowly over the plates. That can take anything from 30 to 45 seconds per vehicle. It takes 12 to 15 seconds on the static weighbridge."

Stokes says the Ross-on-Wye weighbridge by the M50 has been weighing up to 150 vehicles an hour. It is that sort of capacity which attracted the Department of Transport's interest for the busy port installations.

"There will be a few modifications to the Ross prototype at the Newhaven installation," says Stokes. "There will be an automatic axle counter, and on either side there will be a multilingual ticket-issuing device."

The Newhaven weighbridge will take vehicles of up to 18 metres in length and will weigh vehicles of up to 100 tonnes. It will also weigh each axle individually to check for axle overload.

SELF WEIGHING

Because the Newhaven installation will operate as a self-weighing device, it will, at least initially, be up to drivers to decide whether to proceed if their vehicles are overloaded.

"The driver will be advised whether he's overloaded," says Stokes, "so he can be redirected at the port gates to reduce the load or he can take the chance of proceeding."

Stokes hopes the DTp will choose to add a camera to the weighbridge to automatically photograph each vehicle found to be overweight.

The DTp will be installing between 20 and 30 weighbridges at ports to measure incoming commercial vehicles. The exact number has not been decided and will depend on whether weighbridges are fitted at container ports as well as RO-RO ports.

A further 60 installations will be made for weighing outbound commercial vehicles. These weighbridges will be paid for jointly by the harbour companies and the ferry companies operating at each port.

Central Weighing is tendering for contracts to install weighbridges for outgoing traffic at RO-RO ports. "There have been no contracts awarded yet," says Stokes, "but we expect the ferry companies and ports to choose a whole range of different weighbridges according to the circumstances at each installation.

"Most will choose manned and conventional weighbridges because they are interested only in gross weights. . . they have to monitor total weights in the light of the Zeebrugge disaster."

The country's leading weighbridge manufacturers not only expect a boom in orders from the ports and ferry companies, but are also finding that domestic demand for weighbridges is increasing.

"The market is extremely buoyant," says Stokes. "That is primarily because the DTp has increased its enforcement efficiency. There has been a tremendous growth in business and hauliers cannot afford to ignore the perils of overloading. As the enforcement grows our market grows and we extend our services to a wider range of companies."

Stokes is proud of the speed and accuracy of Central Weighing's static weighbridge at Ross-on-Wye, although his company also sells dynamic weighbridges. All the weighbridges are electronically controlled, with interchangeable accessories and software to allow customers to upgrade their systems if necessary. Central's range extends from complete weighbridge systems for large fleets which form part of the customer's computerised fleetmanagement system, to portable pallet weighers, produced by Central Weighing's Australian parent company BWD Industries.

Central Weighing recently won a 2250,000 contract with the North Thames Gas Board to supply axle weighers. It has won other large orders from the Post Office, London Brick, several county councils and the Eastern Electricity Board. The latter is using its weighbridge both for check-weighing its own fleet and for checking the weight of incoming consignments of old cookers.

Stokes believes smaller operators can also benefit from the installation of a weighbridge: "For an operator with one or two vehicles, overloading offences could result in a loss of the 0-licence. That's why we extended our range to include a low-cost electronic system (the series 950) which, for 23,000, will display the axle weights of any vehicle with up to a 15-tonne axle."

Central Weighing can arrange a leasepurchase scheme for its products. Prices start at around 225 a week, but for the Series 950, the cost would be nearer double that.

"Without an axle weigher, the decision of where to place a load on a vehicle is very difficult," says Stokes. "Six inches either way can be critical. You see all the adverts in the press for high-volume, non HGV vehicles, but there's very little attention paid to axle weights or overloading. Companies buy the vehicle to get as much in as they can, but even with a non-HGV vehicle you can get a 21,200 fine and endorsements for overloading."

Stokes believes the weighbridge manufacturers have a major job to educate commercial vehicle users about the benefits of installing weighbridges: "Most of the professional lorry drivers know about the loading tolerances of their vehicles, but the smaller vehicle drivers are oblivious and I still find it amazing that I get large hauliers saying to me, 'I wasn't overloaded on gross, just on the axle'.

"Everyone operating a commercial vehicle has a potential overload problem," says Stokes. "The Government is encouraging people to stay within the law by increasing the levels of prosecution, but more could be done to provide facilities to self-weigh and check-weigh loads around the country. Public axle weighers are very few and far between and the vast majority of public weighbridges are unsuited to weighing axles. . they are often open only from nine in the morning to four in the afternoon, and hauliers can only make an estimate on gross weights. For axle weights, they're almost forced to take a chance."

Stokes expects his company to sell between 100 and 130 weighbridges this year, providing all the design, civil engineering and installation work, as well as servicing and maintenance.

LITTLE THREAT

He sees little threat to his business from on-board vehicle weighers. "We will supply them but we don't manufacture them," he says. "They have not proven to be particularly accurate and they are fairly costly. One vehicle fitted out with the devices can cost more than a weighbridge. I've been in the business 20 years and when I first started, they were talking about on-board vehicle weighers.

"They've progressed very little, and you're still talking about 23,500 to 25,000. Recent tests by the Transport and Road Research Laboratory were talking about accuracies of 2%-3%, but that was on level ground with correct tyre pressures and so on. I'm sure the breakthrough will come, but not yet." Stokes says his static weighbridge will measure to accuracies of 0.33% per axle.

He is bullish about the future market for weighbridgs because he believes there will be growth in enforcement both in the UK and, with time, on the Continent.

"If there is a move to 40 tonnes in this country, the gross weights increase will be allowed providing there is no increase in road wear," he says. "There will need to be greater enforcement. I wouldn't be surprised to see a trebling of enforcement sites during the next three to four years." 13 by Richard Scrase