1. Efficiency is a word which, like many others in

Page 59

Page 60

Page 61

Page 62

Page 65

Page 66

Page 67

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

our ianguage, means different things to different people. There is the efficiency of the individual which can denote his capability, his aptitude, his skill and even his cleverness. In an organization it tends to reflect its efficacy and adequacy in performing its appointed tasks. These various meanings have their place when one studies efficiency in road passenger transport.

2. Passenger transport is a service provided for people by people and because it operates in small units it is very much a labour intensive industry. The efficiency of the individual worker—whether

he is in the operating grades or in management must be of paramount importance to success. But an efficient individual is severely handicapped unless the organization within which he works is itself efficient.

3. I propose to examine the structure and the operational and financial problems of the bus industry from certain standpoints so as to explain the present position and to give my personal views on the standards of efficiency which might be applied and the help which should be given to reach these standards. I think it would be convenient to take the following broad headings:— (i) Operational: WI Organizational, covering management and general structure; (iii) Training and Research: (iv) Technical and Engineering.

Operational

4. The operational aspect is the one which perhaps touches the bus passenger closest and it certainly covers a wide field. It starts with the timetables of the services and the fares which are charged for the journeys. Ideally the passenger wants a bus to take him at a fast speed from his home or other convenient picking-up point direct to his destination with the minimum of waiting time at the bus stop. To cater for such demands—a good deal of which is only spasmodic —would involve charging fares at a level which would be wholly unacceptable. Some compromise is necessary and this is where the skill of traffic managers must be applied. Services must be so devised that they cover a number of traffic points which will provide a reasonable number of passengers on the bus to warrant its operation. This means too that the frequency of the service must also be determined according to the number of passengers seeking to travel. With this pattern in mind the traffic manager should be able to judge what fares he must charge to cover his running and overhead costs and to leave a small margin of profit. He has, nevertheless, to take the rough with the smooth and accept responsibility for some non-paying journeys within his area, financing them by cross-subsidization from the good routes and from more popular timings on the same routes.

5. All this may seem elementary when stated in this bald way, but it is surprising how few passengers seem to recognize these facts of transport life, and vociferously protest about having to wait for a bus, about the exorbitant fares and about the devious route followed. And even local authorities and other responsible bodies are equally uninformed on the economics of bus operation (and—dare I say it?— politicians as well). Almost everybody regards himself as an expert in transport but, in fact, a high degree of specialization and management expertise is called for. The test must therefore be how efficient is the compiler of timetables and fare tables.

6. The demand can usually be calculated without great difficulty. Most of the services have grown up and developed over a long period of time and records of the fluctuating traffic are available. This information is supplemented by knowledge of new housing estates, new factories and new schools, as well as by letters from passengers and by representations from the local councils. The next step is to decide on the number of journeys needed to provide a reasonable service for this demand. It then falls to the traffic department to work out how to operate these journeys so as not only to meet the agreed requirements but also to provide them at the optimum balance between cost and service.

7. Much of this activity is necessarily imprecise and not subject to scientific regulation. Fortunately, the larger undertakings—whether company, municipal or independent—have in the course of time collected together and trained a number of experienced and skilful schedules clerks who, in my opinion, produce as efficient schedules as is possible, given the complexity of the factors which have to be taken into account. My opinion is reinforced by the three-year research undertaken under the auspices of the Tilling Bus Group at Liverpool University. We were fortunate in having the enthusiasm and untiring energy of Professor Young to head this research. Although he started off with the idea that a computer would solve our problems and provide more efficient schedules than those we had, he finally came to the conclusion that within the existing constraints no computer at present available could improve on what the experienced schedules clerks were doing. He summed it up by remarking that in this sphere the best computer was the trained human brain.

8. I should perhaps add here that the schedules clerks have to take into account the manning problems involved in the compilation of the duties. This includes availability of staff—and in many areas there is a serious shortage—and acceptability to the trade union representatives. Apart from the national agreements on wages and conditions of service, each undertaking has its own local agreement with the union and as these have been negotiated over a period of many years and cover local demands and preferences by the staff, they differ greatly from one undertaking to another and even between depots in the same undertaking.

B. These considerations, taken in conjunction with the heavy weight of service during the peak hours and the relatively light requirements in the non-peak periods, pose great problems for the schedule compiler. His task would be made easier and the schedules more efficient and there could be a marked improvement in manpower utilization if bus undertakings could recruit part-time drivers and conductors as well as seasonal staff to help out in the more intense periods of operation. A better usage also of both vehicles and staff could be obtained if there were a more realistic and understanding approach to the staggering of working hours in factories and schools: even a small adjustment would make a considerable contribution to operational efficiency and would enable undertakings to employ labour more effectively. Exhortations in this field, however, seldom evoke sympathetic responses. 10. A further complication lies in the recent proposal by the Minister of Transport to shorten the statutory hours of work by drivers. This may be an ideal which one would seek to achieve but is largely impracticable when one considers the weight, and especially the irregularity, of the demand and the obvious difficulty of meeting within economic bounds the requirements arising from holidays, sickness and other absences of staff. The industry does not accept that the alteration of hours is necessary from the passengers' standpoint because its safety record (see Fig. 1) has been excellent and the vehicle design and the standards of drivers' comfort and effectiveness have been gretly improved since the original statutory limits on drivers' hours were imposed.

11. Broadly then the aim of operation is to keep costs at their lowest practical level. This is essential if we are to succeed in our aim of providing efficient and convenient services at fares which the public can afford—in other words, and in the wording of the Road Traffic Act, at fares which are reasonable. This is the art of management: so we must turn to the organization behind the operating departments.

Organization

12. What is the ideal organization? We enter the realm of economic thought and political theories. Some people advocate large regional transport boards which will unify, own and operate all bus services over a wide area, but experience has shown in the BET Group as well as in the Tilling and Scottish Groups, that smaller operating units hold their own so far as efficiency is concerned. The structure must be live and sound. It should produce clear judgements and informed decisions at the top and it should have a good means of communicating its policy to all levels. Economies of scale do not operate in the bus sphere as they do perhaps in other industrial undertakings. Within the agreed policy there is need for flexibility and for local and immediate supervision which is capable of taking quick on-the-spot decisions. To quote from the Transport Holding Company's report for 1965: "In such circumstances the net advantage of the relatively small unit may well exceed the benefits offered by an advanced technological direction which is placed, inevitably, remote from the actual scenes of action. What is needed is direct, fully responsible management, on the job, and a strong but short chain of managerial command".

13. This summarizes my own views on the size of operational units. Whether the optimum size is around 700, 1,000 or 1,500 vehicles will vary according to the extent and urban density of the territory covered. The Ministry of Transport in its evidence to the Royal Commission on Local Government in England seems to support the view that an undertaking running more than 1,500 vehicles becomes inefficient in the best managerial sense.

14. It is largely for this reason that the Transport Holding Company, although nationally owned, has retained the operating companies which it inherited without welding them into large scale impersonal transport boards. The names some of them picturesque and with an old-world flavour—are still seen throughout the country and have considerable value in the field of local pride. I doubt if the average passenger knows whether the bus or coach he travels on is publicly or privately owned: it is just his local bus under local management.

15. This does not mean that names and operating units are retained regardless of efficient control. Territorial boundaries are varied where these changes can add to efficiency. For instance, some years ago a large section of the Eastern National company was transferred to the United Counties company: a wholesale exchange of territories took place between the Red and White and Bristol companies in the Stroud and Forest of Dean areas: and the Western National handed over their Stroud area operations to the Bristol company. On the management side, Wilts and Dorset have come under Hants and Dorset control and in the Midlands the Mansfield, Midland General and Lincolnshire companies have been placed under one general manager. But in all these companies the fleet name and livery are retained. By unifying the control the benefits of securing the optimum operating size are obtained and there is a larger area over which to give crosssubsidization by supporting the lean rural routes from the receipts on the more profitable urban and inter-urban routes. Even the BET Group, which has a complication in the different shareholdings in its companies, has followed the same pattern by appointing one general manager over the Western Welsh and Rhondda companies.

Co-ordination

16. Another method of increasing efficiency is through agreements between operators. This ensures that the maximum use can be made by the public of all buses operating along a given route or in a specified area. Such co-operation in the form of pooling agreements goes well back in history and is widespread among company operators, but in certain cases it has taken a more advanced form in municipal/company co-ordination schemes of which the local undertaking, the West Yorkshire Road Car Company, were pioneers in the schemes at Keighley in 1932 and at York in 1934. Similar patterns were followed in other parts of the country and they have all stood the test of time. Undoubtedly they have increased the efficiency of local operation: not only are all buses running within the area available to the public but, by reason of reduced operating costs, fares have been kept lower than would otherwise have been possible. It seems to me that development and extension of such co-ordination schemes are in the best interests of efficient operation and could well give the Government what it is seeking to achieve in conurbations and elsewhere—and without involving the heavy cost of acquisitions. Co-ordination has the advantage of preserving the separate units of operation without amalgamating them into an undertaking which is too.big and where it is difficult to maintain the same standards of efficient control. What is even more important, it retains individual managerial responsibility and accountability.

17. Efficiency in rail passenger transport is no concern of mine in this paper, but road/rail co-ordination is. An important study of operational co-ordination was recently undertaken by a Working Party consisting of senior representatives of British Railways and London Transport as well as of the BET Group and the Tilling and Scottish Bus Groups. As a result the Road/Rail Standing Joint Committees were revitalized and the whole machinery of joint consultation has been strengthened so that there is much more direct contact down to lower levels, i.e. station masters and bus depot superintendents. This is where effective co-ordination starts. It is noteworthy that on some routes rationalization of rail services has been carried out in conjunction with road, resulting in better arrangements for connections. Joint enquiry offices arid joint publicity throughout the passenger catchment areas have also been instituted in most parts of the country.

18. Bus-train connections have been the subject of repeated consideration for 30 years or more, but I am satisfied that, on the whole, what is reasonably practicable is being done. Arrangements have, however, to be made to suit the majority and with due regard to economy of operation. It would be unreasonable to expect that bus services which have been carefully devised to meet the convenience of the majority on a route should be distorted to suit a small minority of rail passengers.

19. Another useful outcome of these studies by the Working Party was the planning of combined timetables which included all passenger services in an area not only bus company and bus independent, but also rail, ferries and even air and shipping. Standard signs have also been agreed and will be fixed at convenient points directing the public to the nearest railway station, bus station and bus stop.

Congestion

20. The hard work and enthusiasm of traffic staff are becoming more and more frustrated by the severe congestion on the roads. This has now become a problem affecting the whole community whether people travel by car or by bus but, although many studies have been made of the subject, no effective remedy has yet been found. Two reports have recently emanated from the Ministry of Transport and give the official thinking on possible measures of alleviation. These are "Better Use of Town Roads" and "Cars for Cities". These reports recognize that the growth of car ownership can be expected to continue to erode the viability and hence the competitiveness and perhaps the efficiency of bus operation. They further state that if a satisfactory means can be found to restrain car commuting it would improve traffic flow so much that public transport would become more attractive, speedier and more reliable.

21. The problem is apparent. But what is being done to help the bus to get through and operate efficiently? We can leave the controversial road pricing theories to the economists and the politicians. The current and more practicable measures are to be found in traffic engineering techniques and in parking controls. Much is being done in this sphere to give the bus some priority on the road. Reserved bus lanes have been instituted in some towns and there have been more ambitious schemes in other towns. Portsmouth, for instance, conducted an experiment this year when the main shopping street was restricted to buses only—and with unexpectedly favourable reaction all round. Polperro, the Cornish seaside resort, banned all private cars within a radius of two miles. At Runcorn New Town a reserved highway for buses is being built to link the residential and industrial districts with the town centre (see Fig. 2). Many other schemes are planned in towns and cities throughout the country and if adopted these should increase the speed and thus the efficiency and attractiveness of buses.

22. Although congestion does arise on rural and country roads serving popular districts, this can only be cured by more and better roads. The real problem is urban congestion. Cheaper or subsidized bus fares will not in themselves persuade the motorist to leave his car at home. He must be assured that he will travel comfortably and conveniently and at least as quickly by bus. An effective policy to secure these aims must depend more on those outside the transport industry than on those within it.

One-man operation

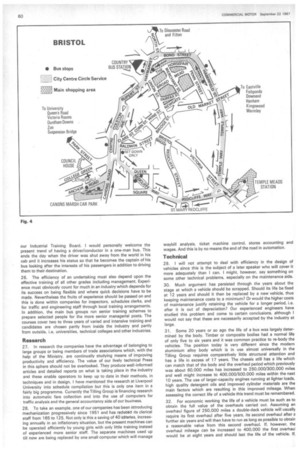

23. There has been, within the past few years, considerable progress by bus operators in the switch to one-man operation. This has resulted in the more efficient use of manpower and has also contributed to keeping down the level of fares. There has been strong opposition to such proposals by the unions in some areas, largely on account of mistaken fears of redundancy, but common sense has prevailed in most areas and the increase in this type of operation in the Tilling Bus Group is shown in Fig. 3. What is needed is an extension of this type of operation to heavy urban routes, but here there must be a simplification of the fares structure and an easier method of ticket collection and control. Research in this field is proceeding actively. 24. An interesting operational experiment has been the Red Arrow service in London and the City Centre service in Bristol (see Fig. 4) which links the railway and bus stations with the main traffic points of the city. Flat fares are charged and there are special ticket issuing and passenger control arrangements on the bus. This type of one-man operation would be appropriate and effective on urban routes.

Training

25. The individual driver and conductor must obviously be trained and must be trained not only technically but also to a high degree of public service since they are in direct contact with the passenger. His or her efficiency will, to some extent, depend upon natural abilities and courteousness which involves the selection of the right people on first recruitment. But training is vital. And here I think it would be accepted that all the major operating undertakings do extremely well in times when it is not always easy to find people who are prepared to work unpopular hours of duty. The training of drivers and conductors has been both intensive and well adapted to present-day circumstances—a fact which I have no doubt will be recognized by our Industrial Training Board. I would personally welcome the present trend of having a driver/conductor in a one-man bus. This ends the day when the driver was shut away from the world in his cab and it increases his status so that he becomes the captain of his bus looking after the interests of his passengers in addition to driving them to their destination.

26. The efficiency of an undertaking must also depend upon the effective training of all other grades including management. Experience must obviously count for much in an industry which depends for its success on being flexible and where quick decisions have to be made. Nevertheless the fruits of experience should be passed on and this is done within companies for inspectors, schedules clerks, and for traffic and engineering staff through local training arrangements. In addition, the main bus groups run senior training schemes to prepare selected people for the more senior managerial posts. The courses cover two to three years of varied and intensive training and candidates are chosen partly from inside the industry and partly from outside, i.e. universities, technical colleges and other industries.

Research

27. In research the companies have the advantage of belonging to large groups or being members of trade associations which, with the help of the Ministry, are continually studying means of improving productivity and efficiency. The value of our lively technical Press in this sphere should not be overlooked. They produce well-informed articles and detailed reports on what is taking place in the industry and these enable operators to keep up to date in their methods, in techniques and in design. I have mentioned the research at Liverpool University into schedule compilation but this is only one item in a fairly big programme. Currently the Tilling Group is financing research into automatic fare collection and into the use of computers for traffic analysis and the general accountancy side of our business.

28. To take an example, one of our companies has been introducing mechanization progressively since 1951 and has reduced its clerical staff from 165 to 125. Not only is this a saving of 40 saarles, increasing annually in an inflationary situation, but the present machines can be operated efficiently by young girls with only little training instead of experienced more senior staff. The separate machines used up till now are being replaced by one small computer which will manage waybill analysis, ticket machine control, stores accounting and wages. And this is by no means the end of the road in automation.

Technical

29. I will not attempt to deal with efficiency in the design of vehicles since this is the subject of a later speaker who will cover it more adequately than I can. I might, however, say something on some other technical problems. especially on the maintenance side.

30. Much argument has persisted through the years about the stage at which a vehicle should be scrapped. Should its life be fixed at 12 years and should it then be replaced by a new vehicle, thus keeping maintenance costs to a minimum? Or would the higher costs of maintenance justify retaining the vehicle for a longer period, i.e. after it is out of depreciation? Our experienced engineers have studied this problem and come to certain conclusions, although I would not say that these are necessarily accepted by the industry at large.

31. Some 20 years or so ago the life of a bus was largely determined by the body. Timber or composite bodies had a normal life of only five to six years and it was common practice to re-body the vehicles. The position today is very different since the modern aluminium alloy body which is in use almost universally in the Tilling Group requires comparatively tittle structural attention and has a life in excess of 17 years. The chassis still has a life which can match that of the body and the overhaul period which previously was about 60,000 miles has increased to 250,000/300,000 miles and well might increase to 400,000/500,000 miles within the next 10 years. The use of larger-capacity engines running at lighter loads, high quality detergent oils and improved cylinder materials are the main factors which are resulting in this improved mileage. When assessing the correct life of a vehicle this trend must be remembered.

32. For economic working the life of a vehicle must be such as to obtain the full value of the overhauls carried out. Assuming an overhaul figure of 250,000 miles a double-deck vehicle will usually require its first overhaul after five years, its second overhaul after a further six years and will then have to run as long as possible to obtain a reasonable value from this second overhaul. If, however, the overhaul mileage can be increased to 400,000 the first overhau would be at eight years and should last the life of the vehicle. If, eventually, it is possible to obtain units capable of 600,000 miles, then a life of 12 years without overhaul is possible and it may then be expedient to scrap vehicles at 12 years.

33. In the Tilling Group we estimate that if the whole fleet were depreciated over 12 years the annual amount to be charged in depreciation would be approximately £3.7 million. With the present extended life depreciation is £2.8 million, so that an increased charge of £900,000 would result. The sum saved on overhauls would be in the order of E200,000 and although a 12-year life would give us a more modern and attractive fleet, we should inevitably face an increased yearly charge of £700,000 in addition to the increased capital involved.

34. Many people consider that passenger appeal is of prime importance and that an old, out-of-date vehicle can do much harm to the reputation of the company. On the other hand, others think that so long as the vehicle is kept in sound condition and well appointed, it is quite suitable for peak and workmen's services especially if the routes are not more than about five miles in length. Another factor is that with the difficulty in retaining a full driving staff and with increased congestion on the roads, it is more than ever necessary to make the drivers' tasks easier and more attractive.

35. I consider that at present the vehicle life should remain at 16/17 years and that larger engines, automatic control and better oils should be used to improve engine life and decrease the number of overhauls. But the situation must be kept continually under review in the light of the prices and costs prevailing at the time. It does not, however, appear probable even then that the savings which can be made would justify disposing of a sound chassis and body structure at 12 years.

36. In ancillary equipment for the maintenance of vehicles I might mention two useful contributions to efficiency. First, the mechanical washing equipment and the large "Cyclone" vacuum extractor which enable a bus to be washed and cleaned out within a few minutes and with a reduction of over half the cleaning staff effort previously required. Secondly, the static brake testing machine which allows brakes to be tested and adjusted in a depot—also within a few minutes—a job which normally involves two men testing over a period of roughly one hour on the public highway. 37. To sum up, how efficient is the passenger transport industry? It has been seen that transport efficiency is not just a technical exercise. The emphasis must always be on the personal aspects involved, both in operation and control. The frequency and convenience of services operated will vary according to the number of potential passengers and the financial stability of the operating undertaking. The number of passengers carried, despite the growth in private car ownership, will have some relation to the attractiveness of the vehicle and the attractiveness of the service. The present speed of bus services is a handicap. If it can be increased by reserved highways or traffic lanes or by traffic engineering techniques, or even by purposedesigned new towns such as Runcorn, some of the passengers lost to the private car could be won back.

38. The level of fares, however, is still an influence but not so great as people imagine. If the service is good the public would be prepared to accept some increase in present fares. Fares must be affected too by the future trend in staff wages as well as by national impositions such as taxation, training levies, redundancy levies, national insurance rates and the like. Some off-set of these charges might, however, come from a wholesale switch to one-man operation and by a more realistic attitude by the unions to the elimination of restrictive practices and other "old Spanish customs". In "deep rural" areas the bus runs into economic difficulties which are a national and social problem dependent upon broader and perhaps political influences.

39. Although I have said that passenger transport operation largely depends on personal control, we must not despise or relegate technology to an obscure place in the background. It would be foolish and unprogressive to do so. What automation, work study and similar scientific processes can do are important in their sphere and should be used, but in an industry which must be continually adjusting its operations to the needs of the society it serves, these techniques must be subservient to the personal touch.

40. All this may sound somewhat complacent—as if the bus undertakings are as efficient as they can be. Of course they are not. What I have tried to do in this paper is to show that the industry is not as inefficient as it is sometimes made out to be. In Fig. 5 I show how the Tilling Group is meeting its obligations in miles run, seats offered and return on capital. The return on capital is important to efficient operation, for without it there is no spur to maximum effort in a competitive world. Anybody can trade at a loss. But as in other economic activities profitability is the criterion for investment—and for success.

41. The aim of efficiency is clear. Full scope must be given to initiative and flexibility on which the industry was built in its earliest days. The enthusiasm and competitive spirit of the individual must not be impaired by a top-heavy organization or by a policy of deficit financing which can dull local initiative. The industry has always involved hard work and basically a strong element of common sense. The structure of the industry must also be flexible and adaptable so that the necessary responsibilities and financial disciplines are exercised to produce the best results. Considerable progress towards this goal has been made but there is still some way to go. We must hope that the industry will be allowed to develop its own organization which is built solidly on experience, skill and personal effort. The passenger transport industry, despite its problems and difficulties, is taking many millions of passengers about their business every day with considerable efficiency.

42. Many outside investigations and enquiries into transport have been made within the past few years and I will end by quoting from a recent report by one of them—the Northern Region Passenger Coordinating Committee which made a careful study of passenger transport in the Region. It said: "The almost negligible response from the public to our invitations through the Press to inform us of cases in which public transport could be improved gives an encouraging indication of the state of efficiency of public transport in the Region". THE operational efficiency of a commercial vehicle is directly affected by its design, whatever the criteria chosen for examining this. The commercial vehicle, whether bus or truck, is a very flexible tool and, with few specialized exceptions, almost any vehicle can be used to do a particular job, but the operator will, of necessity, select the design type which his experience tells him will meet his operational requirements for the lowest overall cost. Similarly, the vehicle designer must decide on design concepts which will most efficiently meet the operational requirements of the market at which he is aiming his product. The principal considerations that may determine operational efficiency, in no particular order of priority, are (1) First cost of vehicle.

(2) Running and maintenance costs.

(3) Reliability.

(4) Payload capacity.

(5) Performance.

(6) Appearance.

(7) Safety and driver comfort.

The first two of these are inevitably inter-related but I have decided to consider reliability quite separately from maintenance cost, for reasons that will be discussed later.

First cost, running and maintenance costs

To the chassis designer these considerations translate into factory cost versus life expectancy of his designs. Value analysis is the current tool for assessing the combined efforts of a design, development and production engineering team on any project, but each manufacturer must determine the relationship between first cost and life expectancy which best suits his product markets. His choice of values will be determined by the operational needs of his market and these can be quite difficult to establish.

Economic life of a vehicle may vary between one and 30 years at the extremes. Vehicles are commonly bought for total economic lives between three and 20 years and, of course, there are good reasons for such a wide spread. Bodywork and equipment carried by the chassis can be a predominant factor as this may cost either a great deal less or a great deal more than the chassis and its economic life may. therefore, have a major influence on the chassis life expectancy. The bus industry provides a good example of long economic vehicle life and, in turn, gives the chassis or unit designer the challenge of matching unit life expectancies to simple fractions of the total life expectancy. For example, a bus with an economic life of 15 years may be economically operated if the main unit and body overhauls can be undertaken at every five years. If the designer wants to do better than this, then he must aim to increase unit life by no less than 50 per cent. i.e. to 7-1years. which may be very difficult and may prove uneconomical.

Unit economic life expectancy is also very much connected with the manufacturer's ability to provide a cheap and efficient unit replacement scheme. The manufacturer with a good service of this kind may take this into account in his initial design in order to reduce first cost.

The user will normally plan to replace the vehicle with a new one of like-for-like performance and capacity, when the cost of maintenance is becoming excessive in his opinion. This can be when the aggregate maintenance cost exceeds 60/80 per cent or more of the purchase price of a replacement, depending on circumstances. The major running unit maintenance cost may not of itself determine the economic vehicle life, although on each individual vehicle the user may plan to dispose of the vehicle before the next major unit overhauls are required. Maintenance costs tend to rise with increasing age and mileage but it can be difficult for the designer to establish the main causes of this where he can offer a cheap and efficient unit replacement scheme. tions of the market will tend to dictate long operational life. In these circumstances life expectancy will dominate the design and development thinking of the manufacturer and his choice of unit or equipment designs. The severity of duty, overloading and general abuse will also have to be taken into account. An engine mileage to overhaul can vary by a ratio of at least 3 to 1. according to duty, and body life can vary similarly according to circumstances.

Designing and developing for long life expectancy presents manifold difficulties. Large diesel engines can reach mileages of 500.000 to overhaul or 15,000 hours operation. A 1,000 hr. test programme, run continuously, takes 42 days. To run 5.000 hr. takes seven months. The development engineer must, therefore, devise accelerated tests but these may be unrepresentative of operating cycles and the engineers must, therefore, use quite sophisticated techniques foi correlating the results of accelerated tests to field experience.

In conditions where vehicle life expectancy is low, first cost become: of paramount importance, provided that adequate life expectancy it achieved. Designing for finite life of parts or components may offel the best ultimate value for money to the user. Here again, sophisticatec test procedures can be used for analysing service stresses on components and tailoring their designs to eliminate unwanted materia content so lowering both first cost and weight. Finite life should noi be misunderstood in this context. Its use by the designer assume.1 that he has a clear understanding of the total requirements placer by service conditions on the component in question.

Field service experience is, of course, the ultimate criterion o performance and, for the manufacturer, the ability to analyse fiek service experience effectively, to correlate this to his developmen activities and to utilize the information in new designs, will very much affect his success in the long term. Even so. whenever the lift expectancy of a component or unit is improved, this will unmasl other areas in the vehicle design that will then limit a further extensioi of life to overhaul if this is desired.

Life expectancy may also be affected by technical obsolescence. II the current context of changes in regulations affecting the constructioi of vehicles, the risk of technical obsolescence will have been ven much in the minds of many commercial vehicle operators. The vehicli designer will naturally strive for new designs which are superior v those currently marketed and will do his utmost to create technice obsolescence of the right kind. I believe that the commercial vehich industry is quite free of planned technical obsolescence, which i based on the customer's subjective approach to the product. I believ, that the commercial vehicle industry is hard-headed enough to dee only in the economic facts of life.

The role of the design engineer must, therefore, be to understan, the balance between factory cost and life expectancy of his company's products and work towards reducing the one and extending the other, but in a logical pattern. His target must he to achieve piece-part or unit life expectancies that fall into a clear pattern of mileage or annual use so that the operator can plan accordingly. Unbalanced performance can be uneconomic. Finally, he must be fed with field service information, and co-operation between user and manufacturer will remain a very vital factor in improving operational efficiency of the vehicle. Co-operation is not always the word used in this context, but every point of contact between manufacturer and user can add to the sum total of experience.

Routine maintenance and accessibility

It has frequently been said, with some truth and much feeling, that every vehicle designer or draughtsman should be made to service or maintain his company's products as an essential prelude to his design activities. Certainly accessibility for routine maintenance and stripping down has too often been the "forgotten function" in the overall design and development programme.

If we face facts, maintenance and accessibility studies are a lower priority to the manufacturer than most others but this does not mean that they are not important. Good accessibility on its own will not sell the product. First cost, performance, reliability, appearance, unit configuration and payload may all take precedence even to the purchaser. It is only afterwards, when maintenance is required, that the hard words are spoken and the labour costs analysed.

Vehicle operation is generally regarded as labour-intensive, whether direct labour only or administrative labour also, is taken into consideration. On the face of it. therefore, reducing maintenance labour requirements should be a major design consideration. Very many basic truck and bus designs have been originated with this in mind, but not all have gained acceptance.

Lubrication is an obvious starting point when considering routine maintenance. Its avoidance is perhaps the best answer to the problem and many current vehicle designs show how this may be achieved on suspensions and linkages generally. On vehicles with longer life expectancies, lubricated designs tend to persist, as wearing parts are generally easily replaced and comparatively cheap. Automatic lubrication systems are offered as options by most manufacturers in this class, but these are not as widely demanded by the operator as the saving in routine maintenance labour might suggest. Developments to eliminate lubrication will expand further and further on chassis components. Systems for topping up engine oil automatically have been widely tried and these systems would be widely adopted, perhaps with further development, if all other services could be similarly dealt with.

Better coolant system designs have reduced the need for constant topping, but on passenger service vehicles in particular, the complex cooling and body heating systems are still troubled by hose and joint problems that are currently challenging the designer.

Road spring maintenance, particularly for the large fleet operator, seems almost an anachronism. A great deal of design effort has gone into alternative suspension forms that will both improve ride quality and eliminate much of the routine maintenance and the worst problem of all, replacing and re-working road springs. First cost of these designs has been a major handicap to standardization and yet they may represent less than 3 per cent of the purchase price of a new vehicle in many cases. This underlines why most manufacturers consider first cost as much more important than designing to reduce maintenance.

Brake adjustment is a design area in which automaticity was applied 30 years ago and used extensively on buses, only to fall into disuse because of problems which could have been overcome by design and development techniques, At that time operators generally exhibited little enthusiasm for the savings in maintenance labour that automatic brake adjustment could provide. Automatic adjustment may now be on the way in again, certainly for buses and quite possibly as a standard for some trucks, but operators again do not appear to be particularly enthusiastic. I believe that interest in this feature will grow quite rapidly in the next few years if the systems prove reliable.

Unit exchange is now widely adopted as the best means of keeping vehicles out of the repair shop for the maximum possible time, but all unit exchanges are not as easy as they might be. On many designs. more time can be occupied in stripping detail than is occupied in demounting the unit itself. Nevertheless, the introduction of tilt cabs on trucks has made a major contribution to reducing time required to make many unit exchanges and this feature will almost certainly stay with us.

Against the rising trend in wages, the design engineer must pit his ingenuity if maintenance costs are to be kept down or reduced. Planned reliability of units will be a major factor, coupled with increasing adoption of low-maintenance designs. Unit exchanges must be engineered as simply as possible, as excess value in these opera

tions can offset the manufacturer's own efforts to provide a cheap and efficient unit-exchange system. In the remaining complex of maintenance operations the designer must pay attention to detail on points of accessibility and pay increasing attention to effects of corrosion of parts, units and bodywork. The special problems that noise reduction may present will be discussed later.

Reliability

Manufacturer and operator will be in complete agreement that -prematurefailures are a complete loss. That they occur at all must be an indictment of the manufacturer and yet it is clear that he will take every sensible step to avoid failures of this kind. Premature or unforeseen failures tend to fall into two categories, design faults and quality shortcomings, but design can often have some bearing on the latter.

It has already been said that the design and development engineer should be fed with field service experience and should be able to learn from the hard lessons of the past. On any new design, engineers must be able to draw on this accumulated knowledge and carefully check every failure possibility. Development and proving techniques of the major manufacturers are now formulated in test procedures that put prototype parts and units and vehicles through the worst kinds of operating condition, and the facilities available to industry are steadily expanding. If a manufacturer runs into a design fault and consequent service failure, it can be that his proving techniques have not covered this aspect fully enough and he will undoubtedly revise his test schedules for the future. Operating conditions, however, vary widely and with the steady development in new techniques in the haulage industry, new problems do emerge which may cause the manufacturer embarrassment. The manufacturer, therefore, must keep abreast of all these developments, particularly of equipment, that may be fitted to his chassis, and be prepared to investigate or, if necessary, develop mounting systems, drives, etc., to suit requirements.

But the odds on his prototypes developing troubles are not always good. A 1 per cent premature failure in service can be a serious matter for the manufacturer. A 10 per cent failure rate will practically produce a crisis. His prototype programme may not, therefore, bring together all the factors that result in failure and it may take him time to piece together, from service failure records, the exact causes of the failure and how it may be dealt with. Time will be the designer's biggest enemy under these circumstances.

Where failures originate from quality defects a designer must still be prepared to investigate his possible share of responsibility. The more automated the manufacturing technique, the less risk of component production that is out of tolerance, but a tricky piece of design may rate too high a risk factor for the manufacturing method used and a simplification may lower the demand on the production engineer and shop floor personnel.

Design engineers must always consider the "failure risk" rating for a component in any value analysis exercise. The premature failure of even a simple and cheap component, but so placed that a roadside repair is not possible, can be extremely costly to the operator. Costs of breakdown vehicles, relief vehicles, transferring load and loss of earnings can be considerable, even if the failure occurs close to base. On long-distance operations it can be a very serious matter. This places a heavy responsibility on the designer to ensure that all major running units in particular are designed for the lowest possible failure risk, and cost reduction techniques must be applied with extreme caution in these areas.

In the section of industry that sets out to meet individual operators' requirements, failure risk will be magnified on components produced virtually straight from the drawing board. This is why manufacturers invariably try to avoid modifications to major units, even where their customers may have an apparently very sound reason for the request.

The manufacturing industry has done a great deal to make its products stand up to rugged service conditions in the past 10 years or so. It possibly has not done enough, as during this period vehicle product ranges available have expanded considerably and the manufacturer's development problems with them. Nevertheless, development and proving is now being tackled much more scientifically than in the past and this must inevitably reflect in improved design and manufacturing quality.

Payload capacity and unladen weight

Whether a vehicle operates up to legal weight limits or not, its payload capacity or passenger capacity is an important element in the operator's calculation to determine minimum overall cost per payload ton-mile or passenger-mile.

In the United Kingdom, changes in regulations over the past years have permitted a steady increase in gross vehicle weights on two, three, four or more axles. Dimensional changes have also very much increased the passenger capacities of buses. In this framework, pres sure to lower cost has been more important to the designer than pressure to reduce unladen weight. Yet unladen weight can be of significant importance. In those overseas countries where legal maximum weights have been maintained for a long period and are strictly enforced, the operator is prepared to pay quite substantially in first cost for a significant improvement in payload.

It is axiomatic that weight should be saved wherever this couples with a cost reduction. Intensive research and development into the elimination of unwanted material in conventional designs can produce quite surprising results. Furthermore, higher strength conventional materials are becoming increasingly available and these often permit the use of smaller sections and so justify their higher cost per pound by eliminating weight in a component so that cost may even be reduced. Where cost can be reduced, this provides the driving incentive to the designer and the manufacturer and this will remain his first priority for saving weight.

But beyond this, weight may only be saved by incurring cost by the use of lighter but more exotic materials. Some balance between weight saved and cost incurred must be struck by the designer, but there is no very clear guide line on which he should work at the present time. Should we in the United Kingdom have a period of stability of regulations, coupled with more strict enforcement for all classes of goods vehicles, then I believe that we will establish a ruling cost per pound on weight saved which the operator will be prepared to pay on a new product. There is quite a lot of scope for weight saving but the choice of materials may be limited by other considerations. We have, as yet done little development in the United Kingdom on chassis by comparison with developments in the United States, but a great deal of North American thinking can be applied by the designer in this country, given the right climate.

Where constant payloads are carried such as on passenger service vehicles, reduction in weight can show returns on operating costs. Lower unladen vehicle weight improves fuel consumption, reduces brake and tyre wear and cost savings of 6d. to 7d. per pound per annum have been evaluated.

Finally, the chassis designer can offer body weight reductions if he can guarantee substantially to improve the ride qualities of the vehicle under all circumstances, Here again, we are to some extent bound up with the cost increase that these suspensions may incur but, again, given the right climate, improved suspensions could offer further payload saving to the discriminating user.

Performance

Time saved is not always money to the road transport industry, operating as it does at hours of the day or night that are not always compatible with the industries it serves. Nevertheless, performance can produce significant economic return, as operations in many countries have demonstrated. That these returns diminish as vehicle performance is improved, is clearly understood. The needs of our mobile society must also be considered and so minimum levels of performance will doubtless be set by regulation in most countries within the next few years. Current targets of performance appear to lie in the range of 7-10 h.p. per ton for medium and heavy goods vehicles and rather more for passenger vehicles. With increasing gross weight, this will lead to power units of up to and over 300 h.p., i.e. nearly double the installed power of the average heavy truck of a few years ago.

There can be serious implications in so lifting vehicle performance. For buses, traffic requirements as well as operational requirements are demanding higher accelerations. The comfort and safety of standing passengers sets a limit of about 2 ma. p. h. per second on acceleration, but more significantly, that the rate of change of acceleration is controlled. This requirement can only be met by automatic gearboxes in which continuous power transmission can be smoothly maintained through any ratio changes.

In goods vehicles, also, the transmission can very much affect gradient performance, which has been the main concern of the Ministry of Transport. We are all too familiar with the truck crawling up a hill because, with a wide-ratio constant-mesh gearbox, the driver just has not time to change up into the next gear. Semiautomatic, "hot-shift" transmissions or even multi-speed closeratio gearboxes can make a surprising contribution to improving gradient performance. Reductions in journey time of several hours have been recorded on inter-state haulage in Australia, between alternative transmission systems in the same vehicle.

Semior fully-automatic transmissions are much more durable under heavy traffic conditions than conventional gearboxes with plate clutches, as bus experience has long shown, and for a variety of reasons, therefore, their usage will inevitably expand on all types of commercial vehicle.

Increased power-to-weight can have a very depressing effect on fuel consumption and other running costs. To put this into perspective, it must be remembered that power-to-weight ratios of under 5 h.p. per ton automatically tend to control the driver's ability to vary fuel consumption on an average route as driving technique is, of necessity, to extract the best performance possible at all times. Lifting the power-to-weight ratio to 10 h.p. per ton very much changes the picture For the same average speed over the same route, fuel consumption may even be improved, but the driver now has the ability to use the much superior performance, and the same vehicle, if driven really hard, may show a drop of up to 30 per cent in m.p.g. This may be fully reflected in brake and tyre wear. Brake design must, therefore, keep pace with developments towards improved performance. Brake thermal capacity and life expectancy to re-line may be determined by the proportion of installed power that can be put into the wheel brakes under extreme conditions. For improved performance larger brakes are a necessity.

When the vehicle design engineer provides improved performance this may be at the expense of more costly and heavier power units, transmission and brakes and increased running costs, yet operational efficiency will be improved given the right conditions. Where operating conditions are marginal, the major benefit may accrue to society as a whole, but the driver, rather than the designer, may have the most effect on running costs.

Appearance

Good appearance is a functional as well as an aesthetic requirement for vehicles, and the designer today no longer regards styling as a world apart from engineering.

The vehicle is often the user's shop window, and its basic styling must both suit the vehicle duty and allow the user to impose his requirements on it. The passenger appeal of buses and coaches is very much affected by the public's subjective views on external and internal appearance. and this does affect revenue.

So the chassis or vehicle designer looks on the styling engineer as an integral part of the design and development team, and the stylist may make useful contributions in what, a few years ago, would have been entirely the engineer's province.

Safety and driver comfort

Whilst these aspects cannot easily be related to efficiency of operation in direct monetary terms, they are none the less of considerable importance, and a great deal of design and development effort will be applied by manufacturers to produce vehicles that provide a good working environment for the driver and that are as safe as possible.

The field is a wide one, and the designer is faced with very many requirements that he must satisfy, both in principle and in detail, if he is to produce a good vehicle within the scope of present knowledge.

In tackling vehicle handling generally, the first prerequisite is that of positioning all controls so that, with a range of seat adjustment, any stature of driver can operate all control functions with natural body movements. Efforts to operate controls must also be strictly controlled, so that the combined result is to keep the driver in full command of vehicle handling at all times. Whilst this may sound simple and obvious, it can take many months of design and development time, on rigs, mockups and prototypes to satisfy all requirements. What is important is that any related chassis or cab design problems must be subservient to achieving a good ergonomic result.

Visibility is of parallel importance. Windscreen upper and lower dimensions must be more than adequate in these classes of vehicle, and sun visors should be provided to avoid excessive glare in early morning or late evening. Rear view mirror equipment must be carefully studied and mounted so that rear vision is adequate whatever the type or width of load carried. Windscreen pillar and glazing sections must be carefully studied and positioned to avoid blind angles of vision. Even door windows and their operation must be studied for reversing as well as signalling requirements.

Instrument layouts must be clean and easily read by any driver, and of particular importance is the positioning of lighting and control switches in easily reached positions, but with clear sequence and separation. Warning systems for the functions covered must be clearly displayed, but with increasing complexity in this field, we may come to the general warning system, with subsequent defect-selection methods that are gaining favour in the United States on heavy vehicles.

In the particular field of braking, designers are currently facing a wide choice of alternative systems that meet current and future requirements of legislation in this country. To the manufacturer, it is significant that international agreement on systems and methods is far from being reached, and practice varies considerably from country to country. There are no very clear guide lines for designer or manufacturer approaching new methods of brake control. If he is conservative, he will retain old and accepted methods, while ensuring that they meet current legislative requirements. New methods may have something to offer both to him and the user, but no test programme he can carry out will give final assurance that he has made the gains anticipated. Where safety is concerned, too often the only reliable information may be accident statistics. Noise is a particular problem for the engineer, but one that, in the context of driver and passenger comfort and amenity, he must deal with adequately, quite apart from ensuring that the external noise levels meet requirements in all his markets. The diesel engine is the major noise source in commercial vehicles, and the mechanism by which it radiates this noise is now well understood as a result of research in industry and at universities. Methods for dealing with it at source, in the engine, have been proposed, but no very practical solutions found. Enclosure of the engine is the next best step. To achieve substantial reduction in noise emission demands near cornplete enclosing, which is barely practical as other difficulties become apparent. Control of engine and component temperature become difficult, and accessibility for maintenance may be seriously interfered with. To remain effective, joints in enclosures must be kept sealed, as even very small apertures will very largely destroy the effectiveness of the enclosure. For interior noise, complete sealing against engine compartment noise is absolutely essential. In addition, insulation of the engine bonnet covers, sides and vehicle floor must be done systematically. Weight is an impoaant factor in sound deadening, and all insulating materials must be kept free from oil pick-up that could add to fire risk. Noise is a complex field in which to work, and to achieve good interior noise levels can again demand many weeks or months of work on one single installation. It is not so surprising that accessibility sometimes suffers.

The designer's role

It is clear to roe that good, efficient commercial vehicle design will not be achieved by men lacked away in back rooms, working in a vacuum. You need ideas and good ideas. You need research and development and proving departments to test and double check your designs. You must understand market research, production problems and cost systems. All these are essential, but what is more essential is to keep the engineer close to his product in the field, with the user, with his customer. This is where his designs are finally measured for efficiency.

Finally. I should like to thank Leyland Motors Ltd., British Road Services and London Transport for the assistance provided in compiling this paper.