BODY CONVERSION BECOMES } PORTANT SCIENCE

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

The Business of Converting Bodywork to Fresh Uses, Now That War.-time Conditions are Upon Us, Has Gained

a Fresh Importance

IN these days, every commercial vehicle, new or old, has an added value because the supply available, other than for the armed forces, is likely to be restricted. Also, the supply of metals and timber, other than for Government work, is controlled. Therefore, the utmost use must be made of all material in hand.

From the coachbuilder's point of view, this means that vehicles already in use will, in many instances, be required to carry loads other than those which were intended, also that bodywork, in various stages of assembly in the shops, may be adapted to suit special 'needs.

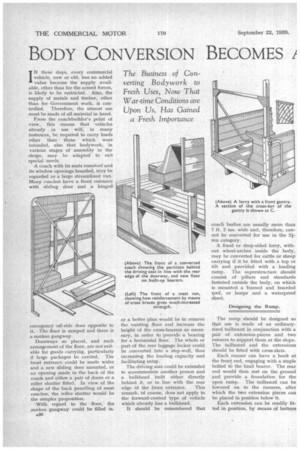

A coach with its seats removed and Its window openings boarded, may be regarded as a large streamlined van. Many coaches have a front entrance with sliding door and a hinged emergency off-side door opposite to it. The floor is ramped and there is a sunken gangway.

Doorways so placed, and such arrangement of the floor, are not suitable for goods carrying, particularly if large packages be carried. The front entrance could be made wider and a new sliding door mounted, or an opening made in the back of the coach and either a pair of doors or a roller shutter fitted. In view of the shape of the back panelling of most coaches, the roller shutter would be the simpler proposition.

With regard to the • floor, the ,sunken gangway could be filled in, A36 or a better plan would be to remove the existing floor and increase the height of the cross-bearers as necessary, in order to provide a bearing for a horizontal floor. The whole or part of the rear luggage locker could be converted into a step-well, thus increasing the loading capacity and facilitating entw.

The driving seat could be extended to accommodate another person and a bulkhead built either directly behind it, or in line with the rear edge of the front entrance. This remark, of course, does not apply to the forward-control 'type of vehicle which already has a bulkhead.

It should be remembered that coach bodies are usually more than 7 ft. 2 ins, wide and, therefore, cannot be converted for use in the 21-ton category.

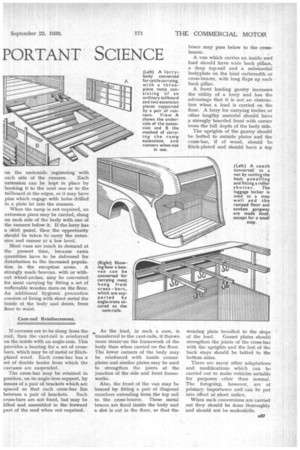

A fixed or drop-sided lorry, without wheel-arches inside the body, may be converted for cattle or sheep carrying if it be fitted with a top or tilt and provided with a loading ramp. The superstructure should consist of pillars and standards fastened outside the body, on which is mounted a framed and boarded ;not or hoops and a waterproof sheet.

Designing the Ramp.

The ramp should be designed so that use is made of an ordinarysized tailboard in conjunction with a pair of extension-pieces and two runners to support them at the slope. The tailboard and the extensions should be fitted with cross-slats.

Each runner can have a hook at the front end, engaging with a staple bolted to the hind bearer. The rear end would then rest on the ground and provide a foundation for the open ramp. The tailboard can be lowered on to the runners, after which the two extension pieces can be placed in position below it.

Each extension can be readily fitted in position, by means of ba.ttpns on the underside registering with each side of the minters. Each extension can be kept in place by hooking it to the next one or to the tailboard at the edges, or it may have pins which engage with holes drilled in a plate let into the runners.

When the ramp is not required, an extension piece may be carried, slung on each side of the body with one of the runners below it. If the lorry has a skirt panel, then the opportunity should be taken to carry the extension and runner at a low level.

Meat vans are much in demand at the present time, because extra quantities have to be delivered for distribution to the increased population in the reception areas. A strongly made boxvan, with or without wheel-arches, may be converted for meat carrying by fitting a set of renlovable wooden mats on the floor. An additional hygienic precaution consists of lining with sheet metal the inside of the body and doors, from floor to waist.

Cant-rail Reinforcement.

If carcases are to be slung from the roof, then the cant-rail is reinforced on the inside with an angle-iron. This provides a bearing for a set of crossbars, which may be of metal or flitchplated wood. Each cross-bar has a set of double hooks from which the carcases are suspended.

The cross-bar may be retained in position, on its angle-iron support, by means of a pair of brackets which are spaced so that each cross-bar lies between a pair of brackets. Such cross-bars are not fixed, but may be lifted and assembled in the forward part of the roof when not required. As the load, in such a case, is • transferred to the cant-rails, it throws more strain* on the framework of the body than when carried on the floor. The lower corners of the body may be reinforced with inside cornerplates and similar plates may be used to strengthen the joints at the junction of the side and front frameworks.

Also, the front of the van may be braced by fitting a pair of diagonal members extending from the top rail to the cross-bearer. These metal braces are fixed inside the body and a slot is cut in the floor, so that the brace may pass below to the crossbearer.

A van which carries an inside roof load should have wide back pillars, a deep top-rail and a substantial bodyplate on the hind earbreadth or cross-bearer, with long flaps up each back pillar.

A front loading gantry increases the utility of a lorry and has the advantage that it is not an obstruction when a load is carried on the floor. A lorry for carrying timber or other lengthy material should have a strongly boarded front with corner irons the full depth of the body side.

The uprights of the gantry should be bolted to outside plates and the cross-bar, if of wood, should be flitch-plated and should have a top wearing plate bevelled to the slope of the load. Gusset plates should strengthen the joints of the cross-bar with the uprights and the feet of the back stays should be bolted to the bottom sides.

There are many other adaptations and modifications which can be carried out to make vehicles suitable for purposes other than normal. The foregoing, however, are of primary importance and can Be put into effect at short notice.

When such conversions are carried out they should be done thoroughly and should not be makeshifts.