The World's Smallest Oil Engine?

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

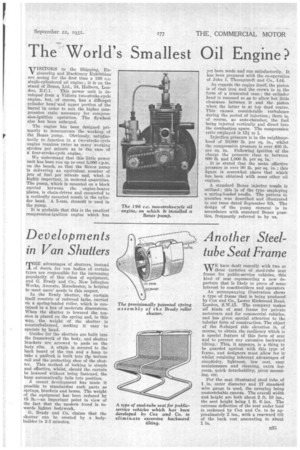

XTISITORS to the Shipping, En V gineering and Machinery Exhibition are seeing for the first time a 196 c.c. single-cylindered oil engine ; it is on the stand of Benes, Ltd., 24, Holborn, Lon

don, E.C.1. This power unit is developed from a Villiers two-stroke-cycle engine, but, of course, has a different cylinder head Nand upper portion of the barrel in order to suit the higher compression ratio necessary for compression-ignition operation. The flywheel also has been enlarged.

The engine has been designed primarily to demonstrate the working of the Belles pump. Obviously, satisfactorily to function in a two-stroke-cycle engine requires twice as many .working strokes per minute as in the case of rif four-stroke-cycle engine.

We understand that this little power unit has been run up to over 3,000 r.p.m. on the bench, so that the Benes pump is delivering an equivalent number of jets of fuel per minute and, what is highly important, in metered quantities. The pump, which is mounted on a block carried between the engine-bearer plates, is chain-driven and connected to a vertically mounted nozzle in the cylinder head. A 5-mm. element is used in the pump.

It is probable that this is the smallest compression-ignition engine which has yet been made and run satisfactorily. It has been prepared with the co-operation of John I. Thornycroft and Co., Ltd.

As regards the engine itself, the piston is of dast iron and the crown is in the form of a truncated cone ; the cylinder head is recessed so as to allow but little clearance between it and the piston when the latter is at top dead centre. This causes considerable turbulence during the period of injection ; there is, of course, no ante-chamber' the fuel being injected vertically and direct into the combustion space. The compression ratio' employed is 12ito 1.

Injection pressure is in the neighbourhood of 10,000 lb. per sq. in.., whilst the compression pressure is over 400 lb. per sq. in. Following ignition of the charge the pressure rises to between 800 lb. and 1,000 lb. per sq. in. '

It is stated that the mean effective pressure is over 90 lb. per sq. in.; this figure is somewhat above that which has been obtained with some other oil engines.

A standard Benes injector nozzle is utilized ; this is of the type employing a spring-loaded needle. The pattern in question was described and illustrated in our issue dated September 8th. The design of the pump element is in accordance with standard Benes practice, frequently _referred to by us.