Developments in Van Shutters Another Steel tube Seat Frame

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

THE advantages of shutters, instead of doors, for van bodies of certain types are responsible for the increasing noPularity of this class of equipment, and G. Brady and Co., New Islington Works, Ancoats, Manchester, is helping to meet users' needs in this respect.

In the Brady shutter, the curtain itself consists of redwood laths, carried on a spring-loaded roller, which is contained in a box of moderate dimensions. When the shutter is lowered the tension is placed on the spring and, in this way, the weight of the shutter is counterbalanced, making it easy to operate by hand.

Guides for the shutters are built into the framework of the body, and shutter brackets are screwed to pads on the body ribs. A staple is secured to the back board of the van and a hasp to take a padlock is built into tb,e, bottom rail and the protecting shoe of the shutter. This method of locking is simple and effective, whilst, should the curtain be lowered without being fastened, the hasp automatically falls into position.

A recent development has made it possible to standardize such parts as springs, brackets and boxes. The weight of the equipment has been reduced by 15 lb.—an important point in view of the fact that the modern trend is towards lighter bodywork.

G. Brady and Co. claims that the shutter can be erected by a bodybuilder in 2-3 minutes.

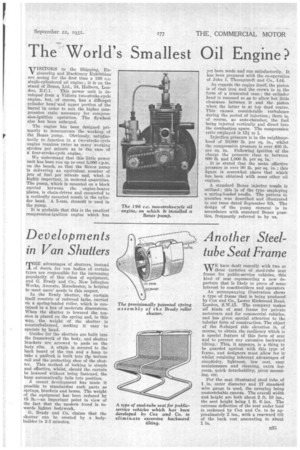

WE have dealt recently with two or three varieties of steel-tube seat frame for public-service vehicles, this kind of seat representing a new departure that is likely to prove of some interest to coachbuilders and operators An accompanying illustration shows a type of frame that is being produced by Cox and Co., Lower Richmond Road, London, S.W.15. The company makes alt kinds of seat frame for private motorcars and for commercial vehicles, and has given special attention to the tubular form of construction. The object of the S-shaped side elevation is, of course, to obtain the resiliency which is a special feature of this form of seat and to prevent any excessive backward tilting. This, it appears, is a thing to be guarded against with this type of frame, and designers must allow for it whilst retaining inherent advantages of simplicity, lightness, low cost, easy maintenance and cleaning, extra legroom, quick detachability, pivot mounting, etc.

For the seat illustrated, steel tube. of 1 in. outer diameter and 17 standard wire gauge is used, the covering being unstre.tchable canvas. The overall width and height are both about 2 ft. 10 ins., the seat height being 1 ft. 6 ins. The extreme deflection of the seat under load is reckoned by Cox and Co. to be approximately 2 ins., with a rearward tilt of the back rest amounting to about 1 in.