An Easily Filled

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

THREE-WAY TIPPING GEAR

Spenborough Unit Attached to Chassis by Six U-bolts

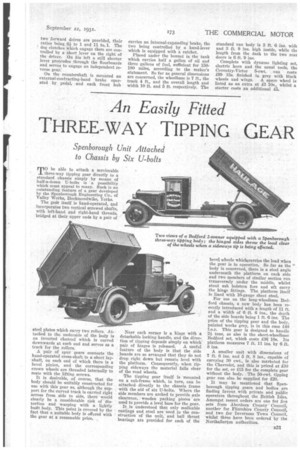

TO he able to attach a serviceable three-way tipping gear directly to a standard chassis simply by means of half-a-dozen ti-bolts is a possibility which must appeal to many. Such is an outstanding feature of a gear developed by the Spenborough Engineering Co., of Valley Works, Reckmondwike, Yorks.

The gear itself is hand-operated, and incorporates two vertical screwed shafts, with left-hand and right-hand threads, bridged at their upper ends by a pair of

steel plates which carry two rollers. Attached to the underside of the body is an inverted channel which is curved downwards at each end and serves as a track for the rollers.

A pair of spur gears connects the hand-operated cross-shaft to a short lay. shaft, on each end of which there is a bevel pinion, and the corresponding crown wheels are threaded internally to mate with the lifting screws.

It is desirable, .of course, that the body should be suitably constructed for use with this gear as, although the support for the curved track is carried right across from side to side, there would clearly be a considerable risk of distortion and warping with a lightly built body. This point is covered by the fact that a suitable body is offered with the gear at a reasonable price. . Near each corner is a hinge with a detachable locking handle, and the direction of tipping depends simply on which'

pair of hinges is released. A useful feature of the body is that the side boards are so arranged that they do not drop right down but remain level with the platform. Consequently, when tipping sideways the material falls clear of the road wheels.

The tipping gear itself is mounted on a sub-frame which, in turn, can be attached directly to the chassis frame with the aid of six 'ti-bolts. Where the side members are arched to provide axle clearance, wooden packing pieces are used to provide a level base for the gear.

• It is understood that only malleable castings and steel are used in the construction of the unit, and ball thrust bearings are provided for each of the bevel, wheels whicbscarries the load when the gear is in operation. So far as the body is concerned, there is a steel angle underneath the platform on each side and two members of similar section run transversely under the middle, whilst stout ash bolsters fore and aft carry the hinge fittings. The platform itself is lined with 16-gauge sheet steel.

For use on the long-wheelbase Bedford chassis, a new body has been recently introduced with a length of 11 ft. and a width of 6 ft. 6 ins., the depth of the side boards being 1 ft. 6 ins. The price of the tipping gear and the body, painted works grey, is in this case £40 f.o.r. This gear is designed to handle 2i tons, as also is the short-wheelbase Bedford set, which costs £36 10s. Its platform measures 7 ft. 11 ins. by 6 ft. 8 ins.

A smaller unit with dimensions of 7 ft. 6 ins. and 5 ft. 8 ins., capable of carrying 30 cwt., is also marketed for the Chevrolet, and this is priced at 130 for the set, or £15 for the complete gear without the body. The 50-cwt. tipping gear can also be supplied for £20.

It may be mentioned that Spenborough tipping gears and bodies are finding favour, with private and public operators throughout the British Isles, Amongst recent orders are one for five sets from Aberdeen County Council, another for Flintshire County Council, and two for Inverness Town Council, whilst three have been ordered by the Northallerton authorities.