At the Engineering Exhibition.

Page 5

Page 6

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

A Further Selection of Machine Tools and Mechanical Novelties are here Described.

C Wit inued from /age 28.1

From the spectacular point of view, the array of machines. at Olympia is by no means comparable with previous exhibitions held in the same building, but visitors who are genuinely interested in the capabilities of the various machines shown, and who are not attracted merely by the display of mechanical power, are finding plenty of interesting features amongst the exhibits. In our last week's issue, we described, at some length, a fee of the exhibits which are of interest to the majority of our readers; we now briefly refer to other stands on which are staged machines and devices that are worthy of the mostcareful attention at first hand by ninny of our readers. Machiaes for the testing of metals are amongst the lessimposing, but not less-practical machines shown by Messrs. Burton, Griffiths and Co. These new testers are intended for use in any works of average size, for the testing of material during the various stages of manufacture into finished parts; it is not necessary to prepare special test pieces--a lengthy and costly operation, but the actual piece of work may be tested in one of these machines without risk that the piece so tested will he spoiled. They are made in two styles—portable and fixed. We are informed that, with them, it is possible to determine, from tests made on a piece of metal : firstly, the hardness of the material, by the depth of penetration of a hardened-steel ball under a constant and known load ; secondly, the tensile strength, by deduction from the diameter of the impression made by the ball; and, thirdly, the elastic limit, by the crushing of a truncated cone under a known pressure.

The machines are made for use with balls of mm. and 10 ram. in diameter. The ball is held in a hardened die, through a hole in which the ball projects nearly one half of its diameter, and below it is a powerful and carefullycalibrated helical spring of known rate. The piece of metal to be tested is placed upon the protruding ball, and a screw-operated plunger is then forced down on the top of the test piece until the latter is gripped between the plunger and the top of the die; the spring underneath the ball yields as the pressure is applied by the plunge', the amount of yield beiug determined by the hardness of the metal, and, on the latter, a clear impression of the ball is left. The diameter of this impression may be accurately measured with the aid of a magnifying scale, and, by reference to a chart which is supplied with each machine, the tensile strength can be obtained. We reproduce one of

these charts, and its use will be made clear if we take a typical example: let us assume that, with a 10 mm. ball, an impression 4.7 mm. or 47 tenths of one mm. in diameter was made in a test piece. From 47 on the left side of the chart, follow the horizontal line across until it is intersected by the plotted diagonal line and from that point, follow the vertical line down to the base; there, we shall find the number 85 given, which number represents the tensile strength of the material in kilos. per square rum., or, roughly, 54 tons per sq. in. The chart must, of course, be plotted specially for each machine.

An impact-testing machine is also shown by this firm. It consists of a hand-driven (through gearing) disc, which is made to rotate at a definite and indicated speed, and, while the disc is running at that speed, a notched test bar, which rests on knife edges, is mechanically pushed forward so that it is struck in the centre by a plate, o:: hummer, which projects from the periphery of the disc. The breaking of the test bar checks the speed of the disc's rotation, and the indicated reduced speed represents the energy (in ft.-lb.) taken out of the disc by the test bar's resistance. A ball-testing machine, of the type a1rea0described, may be mounted on the same base as the impact tester, and the combination of the two devices provides practically all that is required for the workshop testing of materials.

Messrs. Burton and Griffiths are also showing a beautifully-designed all-geared " Milwaukee " plain milling machine, an ingenious automatic twist-drill grinder, and several excellent single-bladed and multiple-bladed cold sawing machines.

Alfred Herbert, Ltd., of Coventry, is showing many first-class examples of modern machine tools, prominent amongst which is one of that maker's hexagon-turrc-t lathes; milling machines, ball-bearing sensitive drills, grinding machines, etc., are also shown on this company's stand, whose order books, we understand, are "full up." So large is the demand for extra plant, mostly, too, froze the motor trade, that the works at Coventry are hard pressed for delivery—a healthy -sign.

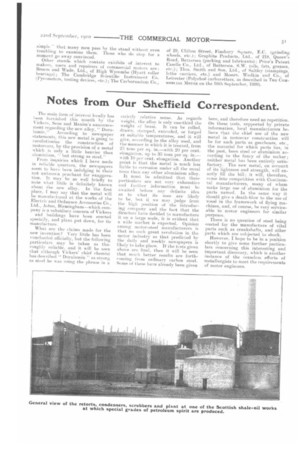

Messrs. J. Parkinson and Sou's stand should not be passed without examinatien of the " Sunderland " gee:shaper, the " 71'wink " lathe, and the No. 2 universal milling machine—the last-named being probably the best value for money of its class. It is an all-geared machine. but, unlike many others of the same class, the mandrel and the feed gears are driven by separate belts. The " Sunderland " gear shaper generates the teeth by means of a cutter which is shaped like a rack—the base from which all toothed gearing is obtained. It will readily be understood that such a form of cutter, suitably relieved, may be produced more cheaply than a hob, and, further, that, with one cutter for each pitch, wheels having practically any number of teeth may be cut with equal accuracy. The rack-shaped cutter is driven backwards and forwards across the face of the wheel teeth, but it cuts in one direction only ; as the wheel is rotated with its mandrel, the cutter is given an endwise movement at a speed which, if measured along the pitch line of the rack teeth,

is equal to the circumferential speed of the wheel's pitch circle. As each tooth is completed, the wheel recedes from the cutter, and the latter then drops an amount equal to the circumferential pitch of the teeth ; the whee' then again approaches the cutter, and the cutting action

proceeds automatically. One of our illustrations shows a partly-cut pinion, and the rack-shaped cutter by which its teeth are being generated.

Parkinson's 7 in. centre " Twink " lathe is a capital tool, and it is typical of the best English practice. It is equally suitable for either workshop or tool-room use. The Archdale Engineering Co., of 173, Battersea Park Road, SW.; the Britannia Engineering Co., Ltd., of Col chester; the Colchester Lathe Co., of Hythe, Colchester;

eunliffe and Groom, Ltd., of Manchester; Hy. Milnes and Co., Ltd., of Bradford; Messrs. Pfeil and Co., of 445, St. John Street, Clerkenwell, E.G.; H. W. Ward and Co., Ltd., of Birmingham : all show representative machines, which are suitable alike for manufacturers and repairers.

The Acetylene Illuminating Co., Ltd., of 268 and 270, South Lambeth Road, S.W., and the British Oxygen Co., Ltd., of Elverton Street, Westminster, S.W., are both giving demonstrations of the Autogenous process of welding with the oxy-acetylene blowpipe, and they are making fresh converts to this practical process daily. The Patent Castings Syndicate, Ltd., of Balfour House, Finsbury Pavement, E.G., is showing a striking array of remark ably-clean castings, which are prepared by the die-cast process; the metal employed is stated to have a tensile strength of 12 tons per sq. in., and the parts do not need any subsequent machining or fitting. One of the illustrations shows a small timing-wheel easing and its cover, both of which pieces were die-cast, and they may be fitted together without any tooling. Fastnut washers, of course, are there: they are shown in all sizes, and for all purposes. All the other novelties

introduced by that enterprising concern, Fastnute Ltd., of 60, Aldermanhnry, E.G., are shown, including its latest— a single-handed pair of grips of the " Footprint" type. It is a tool that will be appreciated by all workmen.

F. Mellin and Co., Ltd., of 60, Salusbury Road, Kilburn, N.W., occupies a stand at which demonstrations are constantly being given with Fournier's saturated-vapour

thermometric devices, the principles of which were described in THE COMMERCIAL Moron of the 30th December

last. When the simplicity and accuracy of these instruments are more-fully appreciated by engineers, they will he employed very extensively. At present, they look " so simple " that many men pass by the stand without even troubling to examine them. Those who do stop for a moment go away convinced. Other stands which contain exhibits of interest to makers, users and repairers of commercial motors are : Broom and Wade, Ltd., of High Wycombe (Hyatt roller bearings); The Cambridge Scientific Instrument Co. (Pyrometers, testing devices, etc.); The Carborundum Co., of 29, Clifton Street, Finsbury Square, E.C. (grinding wheels, etc.); Graphite Products, Ltd., of 218, Queen's Road, Battersea (packing and lubricants); Price's Patent Candle Co., Ltd.. of Battersea, S.W. (oils, fats, greases, etc.); Thos. Smith and Son, Ltd., of Staley (statnpings, lathe carriers, etc.) and Messrs. Wadkin and Co.. of Leieester (Polyrhoe carburetters, as described in THE a0MMi■IRCIAL MOTOR on the 16thSeptember, 190).