KING COAL ON THE ROAD

Page 70

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

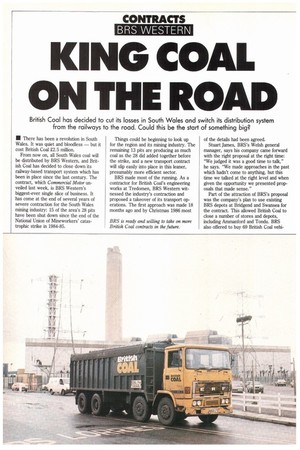

British Coal has decided to cut its losses in South Wales and switch its distribution system from the railways to the road. Could this be the start of something big?

• There has been a revolution in South Wales. It was quiet and bloodless — but it cost British Coal 22.5 million.

From now on, all South Wales coal will be distributed by BRS Western, and British Coal has decided to close down its railway-based transport system which has been in place since the last century. The contract, which Commercial Motor unveiled last week, is BRS Western's biggest-ever single slice of business. It has come at the end of several years of severe contraction for the South Wales mining industry: 15 of the area's 28 pits have been shut down since the end of the National Union of Mineworkers' catastrophic strike in 1984-85. Things could be beginning to look up for the region and its mining industry. The remaining 13 pits are producing as much coal as the 28 did added together before the strike, and a new transport contract will slip easily into place in this leaner, presumably more efficient sector.

BRS made most of the running. As a contractor for British Coal's engineering works at Tredomen, BRS Western witnessed the industry's contraction and proposed a takeover of its transport operations. The first approach was made 18 months ago and by Christmas 1986 most of the details had been agreed.

Stuart James, BRS's Welsh general manager, says his company came forward with the right proposal at the right time: "We judged it was a good time to talk," he says. "We made approaches in the past which hadn't come to anything, but this time we talked at the right level and when given the opportunity we presented proposals that made sense."

Part of the attraction of BRS's proposal was the company's plan to use existing BRS depots at Bridgend and Swansea for the contract. This allowed British Coal to close a number of stores and depots, including Anunanford and Tondu. BRS also offered to buy 69 British Coal vehi des for £750,000 to use on the contract.

No tendering was invited for the contract, but British Coal did put the BRS proposals through a stringent costjustification process.

On the night of Friday 20 March, British Coal's South Wales drivers finished their shifts and took their redundancy cheques. The following Monday fewer than 70% of them were re-employed by BRS Western. With the change of company came a change of union for the drivers, from the NUM to either the Transport and General Workers Union or the United Road Transport Union.

Dr Kim Howell of the NUM says the union was opposed to the transport deal but had no part in the negotiations: the NUM was not even involved in discussions about redundancy payments because an automatic payment award is made to all mineworkers who are made redundant.

WEAKENED NUM

Howell concedes that the switch to BRS has weakened the NUM's hand in any future dispute: "We learned a great many lessons during the 1984/5 strike about transportation by road. A convoy of an unprecedented size moved between Port Talbot and Llanwern three times a day during the strike. We recognise the seriousness of the problem when sections of our membership get hived-off."

In any future dispute the NUM will have to ask TGWU and URTU members to stop transporting coal by road. During the last dispute there were ugly scenes ' when non-British Coal drivers broke through picket lines to drive coal to nearby power stations. With the switch to BRS there would be no NUM drivers for the union to call on for support.

Both BRS and British Coal maintain that the switch to BRS was a smooth one. James says: "BRS benefits from the right culture and we have the framework to build an agreement and understanding with the drivers. We have been involved in several fleet takeovers now and we are better at it — we can do it professionally.

"We put a lot of hard work into bringing the drivers into the BRS culture. At Bridgend and Swansea the drivers have integrated into our existing branches and at Tredegar we have set up a local joint consultative committee." Like other NFC employees, the drivers are able to buy shares in the company.

There are two parts to the transport contract. The first is a six-year contracthire agreement under which BRS will supply 28 eight-wheel tippers and 34 drivers for the movement of coal by road. The South Wales tips currently produce around 10,000 tonnes of coal each week for movement by road, and BRS vehicles haul roughly 40% of that.

The rest of the coal moved by road in South Wales is transported by independent hauliers. BRS will get first refusal on the bulk transport work because British Coal has already paid for the NFC subsidiary's services.

Bob Warner, British Coal's assistant administrative director for South Wales, says: "There are many sub-contractors who can haul coal, however their standards in terms of vehicle presentation, the covering of coal with.sheets, driving to standards and courtesy on the roads cannot be controlled as easily as a dedicated vehicle fleet."

James is confident that BRS can win a greater share of the bulk coal movements in South Wales. The tippers are cleaned regularly and maintained overnight at Swansea and Bridgend. There are changes of shift to fit in with British Coal's requirements. For example, the Central Electricity Generating Board has been demanding a large increase in road deliveries to its Aberthaw power station and BRS has responded to this increased workload with double-shift work.

British Coal is very happy with the bulk movements under the BRS cofitract: "It very satisfactorily meets our new demands in the light of the contraction of the coalfield," it says. None of the 28 ERFs, Leylands and Fodens in the BRS Western/ British Coal tipping fleet carries any reference in its livery to BRS. James says the two companies have yet to meet to negotiate on the vehicle livery. In the meantime the vehicles continue to carry the familiar black and yellow of British Coal — something which Howells of the NUM describes as "disconcerting".

For the second part of the contract BRS is responsible for all distribution of spare parts and equipment to the 13 South Wales pits. This can involve anything from nuts and bolts to earth moving equipment. The man running this side of the contract for BRS is Martin Spinks, formerly assistant branch manager at BRS's Bridgend branch.

SERVICE LEVELS

BRS uses 29 former British Coal vehicles on this part of the contract, all based at British Coal's Tredegar spares depot. Spinks operates the five-year contract to three service levels; four-hour delivery, same-day delivery and as-requested delivery. So far, BRS claims to be achieving 2.5-hours delivery on the first service, 19.5-hours delivery on the second, and same-day delivery on the third.

Mobile emergency winching equipment, which was formerly the responsibility of British Coal, is now serviced and maintained at BRS's Bridgend depot. In the case of an emergency or even an emergency drill, it is BRS personnel who are responsible for transporting the equipment to the incident with the utmost speed.

James is confident about the future relationship between BRS and British Coal in South Wales: "If British Coal decided to go to seven-day working in future we would adjust our operations accordingly. Six-day working will not present us with any problems," he says.

If there are any further pit closures in South Wales, BRS will be able to adapt: "Closures of pits are not a worry at all," says James, "even if the number of pits halved in the next five years it would still be big business for us."

British Coal may well be encouraged by its experience in South Wales to consider similar moves elsewhere in Britain, claims James. It makes sense for British Coal to concentrate its efforts and capital on mining, he claims, while sub-contracting other operations. BRS will certainly be ready fcr action if the call comes.

1:1 by Richard Scrase