STRIKING INNOVATION

Page 72

Page 73

Page 74

If you've noticed an error in this article please click here to report it so we can fix it.

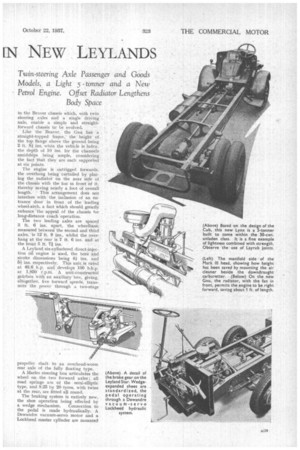

[N NEW LEYLANDS Twin-steering Axle Passenger and Gods Models, a Light 5tonner and a New Petrol Engine. Offset Radiator Lengthens Body Space FOR the 1938 season, there will be three new chassis on the programme of Leyland Motors. Ltd., Leyland, Lancashire, whilst a sixcylindered petrol engine, replete with all modern features, is also a noteworthy item. • The vehicles are the Gnu 40-44-seater, the Steer 104-tonner and the 'Lynx 30-m.p.h. 5-tonner.

' The passenger chassis is undoubtedly the most interesting of the new types from a technical point of view, so we will first deal with this modelThe disposition of the six wheels is at once striking, -the object being to produce a chassis which will give the greatest seating capacity possible on a vehicle of 30 ft. overall length, without the complication of the conventional sixwheeler, or an unusual engine position.

It Is worth noting that, in this new Leyland design, there is a clear floor space, unobstructed by wheel-arches, seated, with good accommodation for luggage alongside the frame beneath the floor.

The manner in which these characteristics have been obtained is not without interest, for, whilst ingenuity has been exploited, the general layout is somewhat reminiscent of a previous and popular Leyland model. We refer to the Beaver chassis which, with twin steering axles and a single driVirig axle, enable a simple and straightforward chassis to be evolved.

Like the Beaver, the Gnu has a straight-topped frame, the height of the top flange above the ground being 2 ft. 81 ins. whin the vehicle is laden. the depth of 10 ins, for the channels amidships being ample, considering the fact that they are each supported at six points.

The engine is out-rigged forwards. the overhang being curtailed by placing the radiator on the near side of the chassis with the fan in front Of it, thereby saving nearly a foot of overall

length. This arrangement does not interfere with the inclusion of an entrance door in front of the " leading wheel-arch, a fact Which should greatly enhance the appeal of the chassis for long-distance coach operation.

The two leading axles are spaced $ ft. 6 ins, apart, the wheelbase, measured between the second and third axles, is 12 ft. 9 ins., whilst the overhang at the rear is 7 ft. 6 ins, and at the front 5 ft. 71 ins.

A Leyland six-cylindered direct-injection oil engine is used, the bore and stroke dimensions being 41 ins. and 5i ins. respectively. This unit is rated at 48.6 h.p. and develops 100 b.h.p. at 1,850 r.p.m. A unit-constructed gearbox with an auxiliary box, giving, altogether, five forward speeds, transmits the power through a two-stage

on the frame beneath the floor of the cab, the shoes expanding within 161-in.-diameter drums on all six wheels. The hand lever actuates the brakes on the centre and rear axles, One of these chassis will be shown at Earls Court with a 40-seater singledeck full-fronted metal-framed body constructed by W. Alexander and Sons, Ltd. All seats face forwards and the entrance is positioned in front of the leading wheels on the near side.

With regard ta the new goods chassis —the Lynx and the Steer—the formei type is sub-divided into two models, both of which weigh under 50 cwt. unladen. A tipping chassis is also to be produced. The smaller of these has a wheelbase of 12 ft. and is rated to carry a gross load of 5 tons 8 cwt., whilst the other, with a 14-ft. wheelbase, can carry 6 tons 8 cwt.

A Good Performance.

Both these machines, together with the tipper, have semi-forward control, which, with little increase in wheelbase, provides the equivalent body space of full-forward-control vehicles combined with good engine accessibility, yet cab accommodation is little inferior to that of the normal-control type.

Based largely upon the design of the Cub range, the Lynx has many new features, apart from the driving position. For example, the braking is entirely new and the engine has been modified to give increased fuel economy, whilst the chassis generally has been cleaned up in detail. As in the Gnu chassis, the braking system incorporates wedge operation for the shoes and hydraulic control.

The power unit is a six-cylindered petrol engine (31 ins. by 5 ins.) based upon that used in the Cub chassis, but with an aluminium cylinder head, which enables a higher compression ratio to be used. Consequently, the unit gives approximately the same power output as the Cub engine of the same size, but with greater fuel economy. The Steer, like its predecessor the Beaver, is a six-wheeled machine with a single rear axle and two steered front axles. It differs, however, from the Beaver in the redisposition of the axles, the adoption of wedge-operated brakes on all wheels, and the positioning of the controls below the top of the frame to facilitate the mounting of the cab.

Gross Total Load, 171 Tons.

These alterations have enabled a noticeable reduction in weight to be effected, so that, as a solo machine, it will legally and safely carry a gross load of 11 tons. Furthermore, owing to the fact that the chassis has been designed primarily for heavy duty, it is equally suitable for regular trailer work in which case an additional gross load of 61 tons can be hauled.

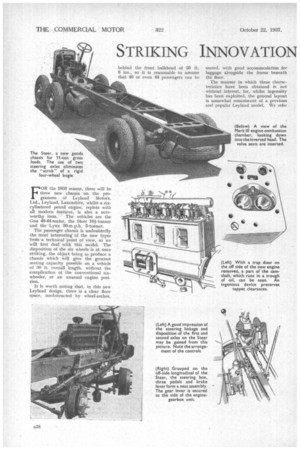

Finally, we have to consider the Mark III petrol engine, which has been developed after many years service experience with the Leyland T-type sixcylindered unit. It is interesting to note, however, that it bears only a n40 slight resemblance to its prototype.

In developing this Mkrk III engine, the designers have aimed at efficiency and economy of operation, attention having been paid at the same time to details of construction affecting the retention of tune for long periods. The major differences between the new and the old types lie in the removal of the camshaft to the block and the fitting of well-studded separate and interchangeable aluminium-alloy cylinder heads, with the valve gear operated by push-rods and rockers. The bore and stroke are 4 ins. and 51 The camshaft is carried in four large bronze bushes on the off side of the block and rotates in a trough of oil, valve operation being effected through rocking levers and short push-rods made from duralumin, in the case of the inlet, and steel in the case of the exhaust, so as to maintain a constant tappet clearance under all operating conditions.

All the major bearings are lubricated under pressure, a gear pump delivering oil through a filter to the main galleries. A supplementary pump supplies lubricant to the camshaft front bearings and valve gear.