NEW FLATE1 'NED CHASSIS Marks Peak in ish Oiler Design

Page 66

Page 67

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

FULL marks are merifed by the manufacturer with the courage to depart from orthodox practice to pursue the path to progress. Shows in the past have rarely failed to produce developments on new lines. Some of these have been spectacular stunts—perhaps meant only to draw the limelight; some have been genuine attempts to improve the breed, but have failed; some have made headway to the lasting benefit of the industry and the public.

This year, we feel justified, at the time of writing, in regarding as the outstanding product of the moment a new series of chassis that has been evolved by TillingStevens, Ltd., Maidstone, and includes the Successor passenger and the Yeoman goods models. We hope that our confidence in forecasting for it a place in the third group outlined above will not prove to -have been misplaced.

This paper has persistently advocated certain of the features it possesses, and it seems that a sound and practical application has been made of the ideas put forward.

A leader in the earliest days of commercial motors, the Tilling-Stevens petrol-electric established an enviable repu. tation. To-day, the Tilling-Stevens Successor and Yeoman chassis may again mark an epoch in the destinies of the movement.

The Successor is a six-wheeled chassis for 44-seater singledeck bodies; the Yeoman is a goods four-wheeler for 8-ton pay-loads. Both have eight-cylindered oil engines of the horizontally opposed type accommodated, between the longitudinal frame members, well behind the front axle.

This unit transmits its power through the medium of a Maybach gearbox, 'affording seven forward speeds and equipped with vacuum-operated preselective control. This component is bolted directly to the back of the engine, transmission thence being by a propeller shaft coupled to a worm-driven rear axle.

The foregoing applies to both models.

Considering now only the passenger chassis, we find that the third axle is formed as a part of the sprung weight, B32 whilst from the differential, jointed shafts transmit torque to the driving wheels. All four bogie wheels are suspended independently by a novel and ingenious system employing coiled, cone-shaped compression springs. Each hub centre is attached to sturdy fitments on the frame by upper and lower twin links, whilst by means of an arrangement of bell cranks and pull rods, vertical movement of each wheel causes compression of the appropriate springs.

In. the case of the goods vehicle, the rear axle is fully floating and the sus pension follows more conventional lines.

The maker's object in devising this interesting and unorthodox chassis has been to satisfy the requirements of passengers, owners and drivers. For the first, greater comfort is required; for the second, economical running and increased carrying . capacity are in demand; for the third, ease of confkl and freedom from fatigue are needed. It is interesting to see how these objects are fulfilled.

With iegard to the eight-cyliqdered power unit, the design tends towards weight reduction, freedom from vibra tion and silent and economical running. Accommodated with ease under the body, it leaves the designer unhampered. in respect of considerations of body space, whether it be for passengers or goods. The former are the first to appreciate improved balance and less noise, whilst the driver derives direct benefit from the same characteristics, particularly in view of the fact that be is remote from the unit instead of being close beside it.

Moreover, the forward driving position, which this layout renders easy to arrange, and which is desirable from other points of view, affords an outlook not easily achieved with conventional layouts.

By the Maybach gearbox and its system of control, gear changing is rendered effortless and calls for the bare minimum of skill. Furthermore, for almost every set of con

ditions there is a suitable ratio. Thus, it is possible for the engine to be run, almost continuously, at its most economical speed, with a full complement of passengers. when towing a trailer, or when running light on open fast roads, or under conditions of busy traffic. These several advantages reflect on all three parties concerned—driver, passenger and owner.

Driving positively at all times, the Maybach gearbox incorporates pairs of helical-toothed gears which are always in mesh. The ratios are obtained by sliding dog clutches which bring into play various combinations of wheels. These have been worked out ingeniously so that a large number of ratios is afforded by the minimum number of gears.

Arguments in favour of independent suspension are well known, and it is recognized that the ability of each wheel to rise and fall independently, in following the irregularities of the road, definitely enhances riding comfort and diminishes frame distortion. On the six-wheeler, eight coiled springs share the load, so that each carries approximately only one-twelfth of the total weight of the vehicle. Thus, a high degree of spring flexibility is permissible. Another 'notable point is that the passenger chassis can be built with a perfectly stiaight frame. Every bodybuilder will appreciate the advantage of this feature.

It is claimed that the machine is extremely easy to control, that the steering is light and that the clutch and gear-change mechanism functions so smoothly that it is possible to make gear changes that are practically undetectable. Furthermore, to do so requires the minimum of _effort on the part of the driver. Efficient braking has also been achieved. The system is described as a combination evolved by the Tilling-Stevens. Girling and Lockheed companies: Facts About Both Models.

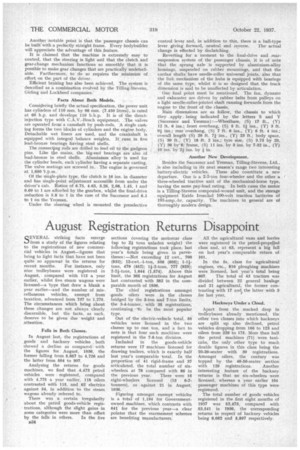

Considering briefly the actual specification, the power unit has cylinders of 110 mm. by 98 mm. (7.450 litres), is rated at 60 h.p. and develops 110 b.h.p. It is of the directinjection type with C.A.V.-Bosch equipment. The valves are operated from a camshaft by push-rods. A single castbig forms the two blocks of cylinders and the engine body. Detachable wet liners are used, and the crankshaft is equipped with integral balance weights. It runs in five lead-bronze bearings having steel shells.

The connecng rods are drilled to feed oil to the gudgeon pins. Like the mains, the big-end bearings are also of lead-bronze in steel shells. Aluminium alloy is used for the cylinder heads, each cylinder having a separate casting. The valve seatings are screwed in. The engine is governed at 1,650 'r.p.rn.

Of thesingle-plate type, the dutch is 16 ins, in diameter and has single-point adjustment accessible from under the driver's cab. Ratios of 6.75, 4.65, 3.26, 2.08, 1.45, 1 and 0.69 to 1 are afforded by the gearbox, whilst the final-drive reduction is 5.8 to 1 in the case of the Successor and 6.5 to 1 on the Yeoman.

Under the steering wheel is mounted the preselective control lever and, in addition to this, there is a ball-type

lever giving forward, neutral and reverse. Theactual change is effected by declutching.

Reverting for a moment to the final-drive and rearsuspension system of the passenger chassis, it is of note that the sprung axle is supported by aluminium-alloy housings, suspended on rubber mountings, and that the cardan shafts have needle-roller universal joints, also that the link mechanism of the hubs is equipped with bearings of the same type, whilst it is so designed that the track dimension is said to be unaffected by articulation.

One final point must be mentioned. The fan, dynamo and exhauster are driven by rubber belts from pulleys on a light needle-roller-jointed shaft running forwards from the engine to the front of the chassis.

Main dimensions are as follow, the chassis to which they apply.. being indicated by the letters S and Y (Successor and Yeoman):—Wheelbase, (S) 17 ft., (Y) 12 ft. 6 ins.; front overhang, (S) 5 ft. q ins., (Y) 3 ft. 9+ ins.; rear. overhang, (S) 7 ft. 6 ins., (Y) 6 ft. 4 ins.; overall length (S) 29 ft. 7f. ins., (Y) 23 ft.; body space, (S) 30 ft., (Y) 18 ft. 2 ins.; tyre size, (S) 9.75 by 20, (Y) 36 by 8; frame, (S) 11 ins. by 3 ins. by 7-32 in., (Y) 10 ins. by 2+ ins, by in.

Another New Development.

Besides the Successor and Yeoman, Tilling-Stevens, Ltd., .is also including in its next season's range two interesting battery-electric vehicles. These also constitute a new departure. One is a 2-3-ton four-wheeler and the other a three-wheeled tractive unit of the mechanical-horse type, having the same pay-load rating. In both cases the motor is a Tilling-Stevens compound-wound unit, and the storage equipment Exkle Ironclad 100-volt traction batteries of 103-amp.-hr. capacity. The machines in general are of thoroughly modern design.