KARRIER Builds a TRACTOR-MAME

Page 74

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

A Striking New Machine Which Can be Used as an Eight-wheeler. Part of the Trailer Weight Can Be Super-imposed upon the Tractor by a Pneumatic Hoisting Gear.

IN recent years mucn progress has been made in the sphere of heavy haulage by tractors and

trailers. It is typical of Karrier enterprise to find that Karrier Motors, Ltd., of Huddersfield, is one of the first British companies to market a design of this class. It is known as the T.T,-type tractor and trailer for 10-ton loads.

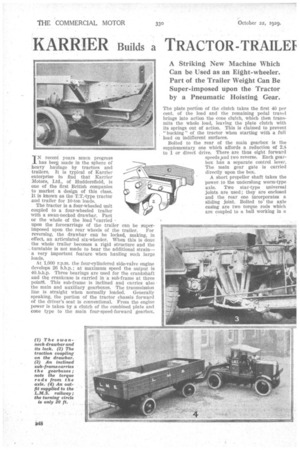

The tractor is a four-wheeled unit coupled to a four-wheeled trailer with a swan-necked drawbar. Part or the whole of the lOad 'carried upon the forecarriage of the trailer can be super imposed noon the rear wheels of the trailer. For reversing, the drawbar can be locked, making, in effect, an articulated six-wheeler. When this is done the whole trailer becomes a rigid structure and the turntable is not made to bear the additional strain-a very important feature when hauling such large loads.

At 1,000 r.p.m. the four-cylindered side-valve engine develops 26 b.h.p.; at maximum speed the output is 40_b.h.p. Three bearings are used for the crankshaft and the crankcase is carried in a sub-frame at three point. This sub-frame is inclined and carries also the main and auxiliary gearboxes. The transmission line is straight when normally loaded. Generally speaking, the portion of the tractor chassis forward of the driver's seat is conventional. From the engine power is taken by a clutch of the combined plate and Cone type to the main four-speed-forward gearbox. The plate portion of the clutch takes the first 40 per cent, of the load and the remaining pedal travel brings into action the cone clutch, which then transmits the whole load, leaving the plate clutch with its springs out of action. This is claimed to prevent " bucking " of the tractor when startingwith a full load on indifferent surfaces.

Bolted to the rear of the main gearbox is the supplementary one which affords a reduction of 2.S to 1 or direct drive. There are thus eight forward speeds ,and two reverse. Each gearbox has a separate control lever. The main gear gate is carried directly upon the box.

A short propeller shaft takes the power to the underslung worm-type axle. Two star-type universal joints are used they are enclosed and the rear one incorporates a sliding joint. Bolted tothe axle easing are two torque rods which are coupled to a ball working in a hbusing; the torque load is taken by the A-arne,

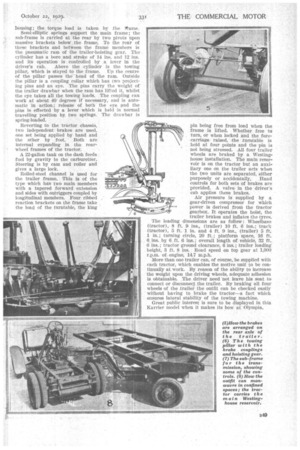

Semi-elliptic springs support the main frame; the sub-frame is carried at the rear by two pivots upon massive brackets below, the frame. To the rear of these brackets and between the frame members is the pneumatic ram of the trailer-hoisting gear. The cylinder has a bore and stroke of 14 ins. and 12 ins. and its operation is controlled by .a lever in the driver's cab. Above the cylinder is the towing pillar, which is stayed to the frame. Up the centre of the pillar passes the headof the ram. Outside the pillar is a coupling collar which has two projecting pins and an eye. The pins carry the weight of the trailer drawbar when the ram has lifted it, whilst the eye takes all the towing loads. The coupling can work at about 40 degrees if necessary, and is automatic in action; release of both the eye and the pins is effected by a lever which is held in normal travelling position by two springs. The drawbar is spring-loaded.

Reverting to the tractor chassis, two independent brakes are used, one set being applied by hand and the other by foot. Both are internal expanding in the rearwheel frames of the tractor.

A 22-gallon tank on the dash feeds fuel by gravity to the carburetter. Steering is by cam and roller and gives a large lock.

Rolled-steel channel is used for the trailer frame. This is of the type which has two main members with a tapered forward extension and sides with outriggers coupled by longitudinal members. Four ribbed reaction brackets on the frame take the load of the turntable, the king pin being free from load when the frame is lifted. Whether free to turn, or when locked and the forecarriage raised, -the turntable is held at four .points and the pin is not being stressed. All four trailer wheels are braked by a Westinghouse installation. The main reservoir is an the tractor but an auxiliary one on the trailer acts when the two units are separated, either purpoSely or accidentally. Hand controls for both sets of brakes are provided. A valve in the driver's cab applies these brakes.

Air pressure is supplied by a gear-driven compressor for which power is derived froth the fractor gearbox. It operates the hoist, the trailer brakes and inflates the tyres. The leading dimensions are as follow: Wheelbase (tractor), 8 ft. 9 ins., (trailer) 10 ft. 6 ins..; track (tractor), 5 ft. 1 in. and 4 ft. 9 ins., (trailer) 5 ft. 1 in.; turning circle, 20 ft.; platform space, 16 ft. 6, ins. by 6. ft. 6 ins.; overall length of vehicle, 32 ft. 6 ins.; tractor ground .clearance, 6 ins.; trailer loading height, 3 ft. 8 ins. Road speed on top gear at 1,000 r.p.ra. of engine, 14.7 m.p.h.

More than one trailer can, of course, be supplied with each tractor, Which enables the motive unit to be continually at work. By reason of the ability to increase the weight upon the driving wheels, adequate adhesion is obtainable. The driver need 'not leave his seat to connect or disconnect the trailer. By braking all four wheels of the trailer the outfit can be checked easily without having to brake the tractor—a fact which ensures lateral stability of the towing machine.

Great public interest is sure to be displayed in this Karrier model when it makes its bow at Olympia.