Patents Completed.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Albion Cylinder Arrangements. Garrett Rotary Adjustment for A Metal-base Solid Tire. A Coil-spring Wheel. Piston-valves.

F. GaanErr and H. K. PRATT, No. 19,071, dated 22nd August, 1913.—In the arrangement described in this specification provision is made for varying the pressure in the cylinder. The cylinder casting encloses a cylindrical liner running parallel with the bore, and in this liner a hollow piston-valve is reciprocated. The ports midway along the cylinder, which are covered and uncovered by the piston, are the main exhaust, while at each end of the cylinder, inlet-ports are provided which are controlled by the piston-valve. Leading from the inlet conduits are passages which can communicate with the exhaust through suitable ports in the liner and the piston-va1ve. The ports in the liner and the piston-valve are arranged obliquely so that by rotating the piston-valve the amount of exhaust which passes through these ports can be determined.

The rotation of the piston-valve is effected by a large handwheel and claw spindle which engages projections on the piston-valve. When the required adjustment of this valve has been effected the claw spindle can be jammed up against the cover of the valve-chest by rotating the small hand-wheel.

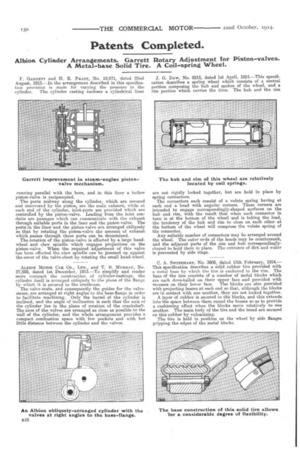

ALBION MOTOR CAR CO., LTD., and T. B. MtrRRAY, NO. 27,592, dated 1st December, 1913.—To simplify and render more compact the construction, of cylinder-castings, the cylinder itself is arranged obliquely to the plane of the flange by which it is secured to the crankcase.

The valve-seats, and consequently the guides for the valve stems, are arranged at right angles to the base-flange in order to facilitate machining.• Only the barrel of the cylinder is inclined, aid the angle of inclination is such that the axis of the cylinder lies in the plane of rotation of the crankshaft. The axes of the valves are arranged as close as possible to the wall of the cylinder, and the whole arrangement provides a compact combustion apace with few pockets and with but little distance between the cylinder and the valves. J. G. Daw, No. 8215, dated let April, 1914.—This specification describes a spring wheel which consists of a central portion composing the hub and spokes of the wheel, and a rim portion which carries the tires. The hub and the rim are not rigidly locked together, but are held in place by spring connectors.

The connectors each consist of a volute spring having at each end a head with angular corners. These corners are intended to engage correspondingly-shaped surfaces on the hub and rim, with the result that when each connector in turn is at the bottom of the wheel and is taking the load, the tendency of the hub and rim to close on each other at the bottom of the wheel will compress the volute spring of the connector.

Any suitable number of connectors may be arranged around the wheel. The outer eras of the heads may be countersunk, and the adjacent parts of the rim and hub correspondinglyshaped to hold them in place. The entrance of dirt and water is prevented by side rings.

C. A. SwnvErtartT, No 3805, dated 13th February, 1914:— This specification describes a solid rubber tire provided with a metal base by which the tire is anchored to the rim. The base of the tire consists of a number of metal blocks which are each dove-tailed on their upper face and provided with recesses on their lower face. The blocks are also provided with projecting bosses at each end so that, although the blocks are in contact with one another, they are not locked together. A layer of rubber is secured to the blocks, and this extends into the space between them round the bosses so as to provide a cushioning effect when the blocks move relatively to one another. The main body of the tire and the tread are secured on this rubber by vulcanizing. The tire is held in position on the wheel by side flanges gripping the edges of the metal blocks.