Motor Depot Management.

Page 2

Page 3

Page 4

Page 5

If you've noticed an error in this article please click here to report it so we can fix it.

With what plant must I equip my motor house, in order that a mechanic in charge may be enabled to keep my fleet of vans or lorries in a thorough and efficient state of repair? This is a question which every businesslike commercial motor user will ask, as soon as he has decided on the purchase of a fleet of vehicles. To this question, we would reply, all depends on three conditions :—(a), the size of your fleet ; (b), the type, or types, of vehicles which you intend to employ ; and (c), the nearness of your motor house to the factory at which the chassis were built. If the motor house is quite close to the works of the maker of the machine, there is, obviously, no need for the keeping of a large stock of spare parts, or for the expenditure of much money on machine or hand tools, except in respect of such of the latter class of look as are needed to effect those little repairs and adjustments which, if done as soon as they are needed, will greatly prolong the useful life of a vehicle. On the other hand, if the works of origin are situated a great distance from the district in which the machines are to be operated, it is very desirable, and indeed necessary (if the vehicles are to he maintained in good working order), that proper provision should be made for the examination and overhauling, at regular periods, of each chassis.

Let us take, for the purpose of an example, the owner of a fleet of, say, ten 30-cwt. or two-ton vans, the average cost of each of which might be :,"5.,00; this would involve a capital outlay of iTc,poo. The expenditure of another :;icio on tools, for the equipment of the motor house, would only mean an additional two per cent. on the capital outlay, but what a lot could be done with those which could be purchased with that Lion! The mechanic in charge of the fleet would have al his command most of the tools that he would need for the effecting of all the ordinary repairs to the machines under his charge. From amongst those enumerated in the following list (all of which are covered by our estimate „4:too), the mechanic would have a tool to meet his requirements for almost any kind of repair.

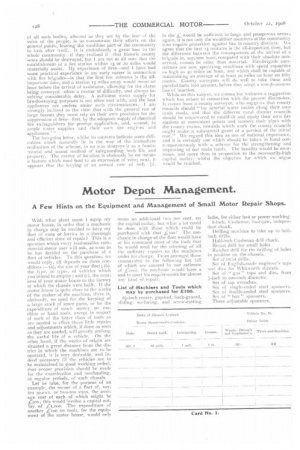

List of Machines and Tools which may by purchased for E100.

*inch centre, gap-bed, back-geared, sliding, surfacing, and screw-cutting lathe, for either foot or power working. 8-inch, Cushman, four-jaw, independent chuck, Drilling machine to take up to halfinch drills.

Half-inch Cushman drill chuck. Breast drill for small holes.

Ratchet drill for the drilling of holes in position 00 the chassis.

Set of twist drills.

Set of English-made engineer's taps and dies for Whitworth threads.

Set of " gas " taps and dies, from .1-inch to one-inch diameter.

Set of tap wrenches.

Set of single-ended steel spanners. Set of double-ended steel spanners. Set of " box " spanners.

Three adjustable spanners. Four pairs of pipe grips.

Quantity of round and square tool steel bar for the making of any special tools or drills which may be required.

One pair each, six-inch, inside and outside calipers.

One eight-inch steel square.

One nine-inch scribing block.

One straight edge, one metre long and divided into millimetres and 1-16ths of an inch.

Three pairs of pliers.

Eight assorted cold chisels.

Three dozen assorted files.

Three hand hammers.

One sledge hammer.

One casosteei anvil.

One 4-inch quick-grip vice.

One 1S-inch, single-blast, oil-fired, or gas-fired, portable forge.

One foot blower.

One large blow lamp.

One pair each, open, round, and flat smiths' tongs.

One iOnch tube vice.

One 18-inch by 3-inch grindstone with treadle gear.

Two screw-drivers.

Half a dozen carpenter's chisels.

One pair of tininen's snips.

One soldering iron.

One engineer's oil can.

One set of 3o-cwt. Weston pulley blocks, with 40 feet of chain.

One 3-ton bottle jack.

To the foregoing must be added any sundry odds and ends, such as a densimeter, oil tanks or barrels, etc., and, if the workshop is not already provided with a line of shafting for power, or unless the lathe is to be driven entirely by foot power, a short mainshaft and countershaft must be fitted up, but our estimate includes the cost of all the necessary fittings for these details.

Tt is understood, of course, that the mechanic who is to have charge of the vehicles will himself carry out the installation of the plant, and we have not, therefore, matte any allowance for labour on account of the establishing, of the tools in the motor house,

So far us power is concerned, we have assumed that electric power is available, in which case a one horsepower motor would be sufficient to drive either the lathe or the drilling machine, and such a motor could be hired from a supply company for about per quarter, or one might be purchased outright for .4.,;10 or .4,12.

We do not, usually, advise commercial motor users to attempt the manufacture at their own spare parts, as these are always better, and more accurate, when made in the manufacturers' jigs and special machines, than could possibly be the case if they were produced itt small quantities in the repair shop. When a spare part is taken from stock, however, it very rarely fits an old machine without needing a little scraping, filing, or grinding ; in some cases, it may be necessary to chuck the new piece in the lathe, and to machine it to the size of the old part.

There are hundreds of uses for which the motorhouse equipment wall be called into requisition, and the fact that the mechanic has the means at hand quickly to effect small repairs, and in some cases extensive repairs, may often avoid the laying-up of a vehicle until some comparatively unimportant part is obtained from the maker of the chassis; such delays may mean the loss of many pounds in revenue, if the vehicle be used for passenger service, or for parcels delivery. So long as a machine is in the repair department, it is not earning money ; the better the equipment of this department, therefore, the quicker will the vehicle be ready for the road again, and earning money for its owner.

Our estimate is, of course, a very modest one. but we venture to state that, if the money is spent in the manner suggested in the accompanying list, the user will get the greatest value for his malaiti capital. More ambitious schemes might he put forward for the needs of larger undertakings, but far such a fleet as we have quoted, or even for a larger fleet of, say, Is machines, the tools which we have listed should, in the hands of a good mechanic, prove equal to the need. The man in charge, however, should have all the assistance, in the wav of extra labour, which he demands, from time to time, for the particular work he has in hand.

The cost at the upkeep of such a repair shop would become a standing charge against the fleet, and the prorot-don to be charged to each vehicle could be allocated in relation to the amount of any of the following : Prime

cost of the machine; the number of miles run per month, or per annum; the number of ton-miles of work per

formed; or a percentage which might be based upon the actual amount chargeable to the vehicle for the labour and materialswhich had been needed for its proper repair.

Undoubtedly, in order to obtain an accurate knowledge of the total costs of running motor vehicles, especially in the eaees of omnibus companies or finite which use a large number of vans or lorries, eome system of entering the costs and proportioning the fixed charges to each vehicle must be car ried out. A task of this sort is no easy matter, and here it is that the card or loose leaf system can be made of great value.

We have, for this purpose, prepared two types of card to be used in con

junction, and adaptable, wi:1-1 slight modification, tor either public or private services.

Card No. v. is ruled off for the entering up of the quantities of petrol, oils, etc., used each day, together with the driver's and the conductor's wages, cost of tires on mileage contract, etc. Each card lasts a week, and is then placed under a special guide card for the vehicle ill question, after the contents have been entered into the costs ledger, together with the depreciation, management mid renewals charges, the last-named being taken from card No. 2.

Card No. 2 is similar in size to that of No. 1, but it contains spaces for renewals or repairs; date; daily mileage; mileage to date; cause of renewals or sundries, according to whichever is desired.

The management and depreciation charges are, of course, predetermined, and should be added to the ACTUAL running costs at the end of each week.

Both types of card contain spaces for such particulars as : make of chassis ; chassis number; date delivered ; body by ; driver ; route; etc., and, as before stated, they should be filed, at the end of each week, under special guide cards which give the number of the vehicle, in a transfer case kept for that purpose.

In some cases, it may be more convenient for more than a week's records to be kept together, in whiah case the loose-leaf type of book is preferable, as the pages may be ruled for, say, a month instead of a week.

The costs ledger (preferably of the loose-leaf type) should be ruled to contain : the fixed weekly charges; the actual running costs; a total of the two ; number of miles run ; cost per mile, or per ton-mile ; and, in some cases, perhaps, the weekly receipts may also be embodied in this ledger, so that receipts and costs may be compared at a glance, and any leakage closely analysed.

Although the conditions under which motor vehicles are operated may differ throughout the country, the suggestions which we have here made should form a useful basis for the establishment of a motor de* and of a system of keeping track of the cost of maintenance of the vehicles, to meet any local or special conditions.

We this week give the text of certain of the resolutions which were adopted, and fairly-full reprints of two papers (by Mr. E. Purnell Ilooley, county surveyor of Nottinghamshire, and Col. R. E. Crompton) :—

Resolutions (First Section).

MATERIALS.

(1.)—The Conference calls the attention of constructors to the necessity of constructing road foundations of the toughest material; this constituent of the road plays an important part, as exerting a considerable influence on the wear and tear of the highway, as well as the upkeep of its profile ; while choosing the foundation system, the structure of the subsoil and that of the road, as well as the character of the traffic using the road, must be taken into account.

(11.1—That a foundation of broken stone 10-15 cm. (say, 4 to 6 inches) thick is particularly recommended in the execution of pavings, even with pavings of -Large size. In this case, the blocks should hare a bed of sand beneath them.

Conference considers that the attempts to incorporate tar with roadlaying materials are of great value.

(IV.)--As a binder to be employed during the passage of the roller, it is recom. mended that a binder appropriate to the nature of the materials, and reduced to the lowest minimum quantity necessary, be used.

(V.)—The ronference considers that the systems of laying blocks obliquely to the axis of the road, or perpendicularly to the axis, should be carefully studied, (11.)—The Conference desires to record that parings in small blocks have been noted as giving excellent results, and

these should be specially studied.

(1.)—The circulation of swift motorcars with pneumatic tires produces on the road surface a dispersion of particles, which increases with the speed of the vehicle, and, in the case of macadamised roads, this disperson increases proportionally with the weakness of the road-binding materials and the substances of which the road itself is composed. This action takes place especially at points where the driving wheels are usually accelerated, and at corners. In turning, the action of centrifugal force tends to increase the tangential effort thz to speed, and to increase the wear and tear.

Studded Treads.

(V.)—For fast cars, it is important to reduce as much as possible the action of the tire on the road surface, by only em.. ploying tires formed of supple materials, and, if fitted with non-skids, the projection of the metal parts should be of the

slightest possible. Although the action of metal non-skids is particularly destructive, the increase of safety they give, both to the driver and the public, is such that it would not be advisable to forbid them.

Heavy Vehicles.

0.14—The tires of heavy motor vehicles of all kinds must be smooth, except in special cases, or on specially-selected roads.

(VI1.)—The passage of motorcars of heavy weight on the highway tends to damage the latter, principally by the for

matioa of ruts. To avoid this, it is necessary that the weight of the load on the axles per centimetre of the width of the tire should not exceed 150 kilograms (say, 750 lb. per inch). It must be remembered that the absolute value of the load on the axle must be carefully considered, rims that are too wide being unable to exercise a uniform pressure on the roadway owing to the camber of the surface. The greatest value of the load on each axle, compatible with a sufficient regard to the roadway, depends partially on the roadway and more especially on the speed of the car.

Special attention was called to the damage alleged to be done to house property owing to the vibration set up by the passing of motor omnibuses.