Schmitz builds m than reefers an

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

It's io years since Schmitz Cargobull laid down its marker on the UK trailer business, haying bought the old York assembly plant at Harelaw County Durham. After a decade of growth with reefers, it's now got its sights on dry-freight, tipper and intermodal buyers.

• by Brian Weatherley It's off cial: Schmitz Cargobull builds more than just reefers. Despite that, most of its UK customers are likely to be running a reefer, or possibly a curtainsider. However, the German trailer giant aims to change all that. It has ambitious plans to grow its current UK market share from 8% (based mainly on reefers) to over 20% with a variety of new models including dry freight, tippers and skeletals. Commercial Motor recently got an exclusive preview of a new product quintet with Al Schmitz Cargobull's UK sales manager/chassis products Colin Ess acting as guide.

CURTAINSIDERS

Schmitz has always offered a curtainsider in the UK—but up until recently they were invariably Germanbuilt 4.0m "Euroliners". However, ear

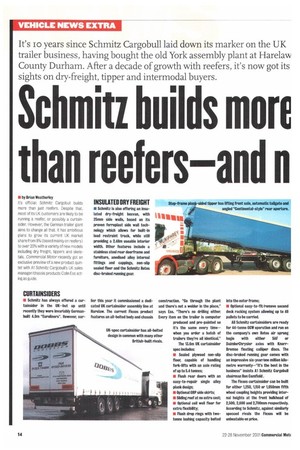

her this year it commissioned a dedicated UK curtainsider assembly line at Harelaw. The current Flexes product features an all-bolted body and chassis construction. "Co through the plant and there's not a welder in the place," says Ess. "There's no drilling either. Every item on the trailer is computer produced and pre-painted so it's the same every time— when you order a batch of trailers they're all identical."

The 13.6m UK curtainsider spec includes; • Sealed plywood non-slip floor, capable of handling fork-lifts with an axle rating of up to 5.4 tonnes; • Flush rear doors with an easy-to-repair single alloy plank design; • Optional GRP side skirts;

• Sliding roof at no extra cost; 11 Optional coil well floor for extra flexibility; el Flush drop rings with twotonne lashing capacity bolted

Into the outer frame; • Optional easy-to-fit/remove second deck racking system allowing up to 48 pallets to be carried.

All Schmitz curtainsiders are ready for 44-tonne GCW operation and run an the company's own Rotas air sprung bogie with either SAF or DaimlerChrysler axles with KnorrBremse floating calliper discs. The disc-braked running gear comes with an impressive six-year/one million kilometre warranty—"It's the best in the business" insists Al Schmitz Cargobull chairman Ron Camfield The Flexes curtainsider can be built for either 1250, 1150 or 1,050mm fifth wheel coupling heights providing internal heights at the front bulkhead of 2,500, 2,600 and 2,700mm respectively. According to Schmitz, against similarly spewed rivals the Flexes will be unbeatable on price.

SKELETALS

Schmitz's 14-lack skeletal is aimed Fairly and squarely at equivalent rolling-bogie models from Dennison, SDC and Montracon and can carry the normal combination of containers and swap bodies including:

t 1 x 21fft boxes centrally mounted; fi 2 x 2Ifft boxes; II 1 x 30ft box mounted from the front pins; P x 40ft/45ft box or a 13.6m swap body.

It features a simple, colour-coded two-position pull-out/fold-over rear twist-lock that works in conjunction with similarly marked double locks on the front bolster. The forwardmost front lock is 850mm forward of the kingpin and is used for all ISO containers; the second front lock sits 700mm ahead of the pin and is used for 13,6m swap bodies—this is the only time when the rear fold-aver twistlock needs to be extended.

According to Ess: "We've developed the unique sliding fold-over rear twist-lock which you can adjust by 150mm whichever front twistlock is being used. With the swap body sitting on the second front look it conforms to the 2.040mm swing radius." The locking rolling bogie has three positions: "Closed" for loading/unloading 20 and 30ft boxes; "Intermediate" for transporting 20 and 30ft boxes; in this position the leading axle lifts automatically depending on weight (28 tonnes can be carried with the axle down; 15 tonnes with it raised);

Ri "Open" for transporting 2x2Oft; laift; 1x45ft; or 1x13,6m swap body when the axle cannot be raised.

The automatic axle function has been designed to meet the new forthcoming lift axle regs (due in 1Jan 2002) when manually operated lift axles will be outlawed.

"Everything on the trailer is controlled by one button for the driver. When the locking pins are withdrawn, the trailer brakes are automatically applied and the lift axle is in the raised position, regardless of weight." says Ess.

Tare weight is 4,950kg on steel wheels (4,800kg on alloys) with the operator having a choice of SAF/DaimlerChrysler axles and paint. "Operators recognise that the durability of previous so-called lightweight skeletals is likely to become an issue at 44 tonnes," reckons Ess who quotes a chassis price of "under £14.000" for Schmitz's rolling bogie skeletal.

R. Schmitz is attacking the tipper market with two basic models: II A 7.2m step-frame chassis with a 64yd5 (49m3) body; and II A 10.5m straight frame chassis dual-role tipper/pallet carrier.

The former is shipped over to Britain as a complete step-frame chassis together with a straight body, which is modified locally into a step body with the tipping ram recessed into a dog house.

The 10m smooth-sided plank body will initially be fitted to a 7.2m triaxle chassis. However, Ess is also looking to bring in a slightly longer 7.48m chassis which will be an "Intermediate-to-maximum length design with a lift axle that will still be capable of operating legally within current turning circle rules."

Like the Flexes curtainsider, the Schmitz step-frame tipper is equipped with Rotos running gear with either DaimlerChrysler or Ski disc-braked axles.

The German tipping semi has an angled rear frame putting maximum weight over the bogie and kingpin, along with an automatic tailgate locking system. A standard stepframe on steel wheels and with Hyva tipping gear (Edbro is an option) tares in at 6.6 tonnes-150kg can be clawed back with alloy wheels.

However, Ess maintains that the Schmitz step-frame is a rugged design that will deliver long-term durability. Typical buyers will be those currently hauling UKASTA-type products, aggregates or coal, he reports. A "bare" trailer without roll sheet or weighing equipment and with steel wheels will be priced at around £21,000.

The 10.5m straight-frame chassis With plank-sided body is sold fully-built and comes with combination doors that can he tap hung for tipping work, or side-hinged. With 2m deep sidewalls body capacity is fily&. Being 2.48m wide internally, the all-aluminium body allows two standard 1,000x1,200mm pallets to be loaded side-by-side inside, making it dual-purpose. "Put a roll sheet on top and it's effectively a tipper and a box van," says Ess.

Like its step-frame twin, the straight-frame Schmitz has Rotes running gear with DaimlerChrysler or SAF disc-braked axles as well as the option of BPW Ecoplus axles with drum brakes.

On steel wheels the straight Schmitz tipper weighs in at 6,9504. "Again it's a rugged design," says Ess. "We don't believe 44 tonnes and lightweight go together—it's a typically robust German product. We'll be selling it on that platform at around £24,000 which will include a roll sheet, front platform, combination doors and grain hatch."