For DRIVERS, MECHANICS & FOREMEN.

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded rack week to the Fender of the b'est letter which we publish on this page ; all others are paid for at the rate of a penny a line, with an allowthee for photographs. All notes are edited before being published. Mention your employer's name, in confidence, as evidence. of good faith, Address, D., M. and F. "The Commercial Motor," 7-15, Rosebery Avenue, London, E.G. 1. • Lamps Alight— Light your lamps at 4.31 in .London, 5.2 in Edinburgh, 4.21 in Newcastle, 4.32 in Liverpool, 4.34

• in Birmingham, 4.42 in Bristol, and 6.19 in Dublin.

Boring a Gearbox by Hand.

The sender of the following ,communication has been -awarded the 10s. prize this week.

[1802] " E.W. (Birmingham) writes :—" When overhauling a gearbox recently, I discovered that one of the ball-race housings had become loose in the gearbox casting. On making a closer examination, I found that the hole in the box had worn to a distinct oval shape. No doubt when new the housing had been a, slack tit, play had developed, and this wear was the . inevitable result. The method of repair was obvious, and-a, steel sleeve was shrunk on to th.e housing, the hole in the box being bored out to suit. As we had no suitable machine on which to perform the latter 'operation, the method .adopted, which involved boring by hand, may be worthy of note. •

• 'It should first be mentioned that the worn hole was in the direct line of another one, at the opposite end of the box, the opposing hole being, however, true and unworn. A steel bar was procured, long enough to serve as a boring bar, and this was mounted in a, guide which was centred in the unworn bored hole in the box, already referred to above. The sketch (which we have had re-dra,wn.—En.),will make this description clear. A suitable boring tool, made from in. round tool-steel bar, was fitted to the 'business' end of the boring bar,,and to the other end a handle, of in. round iron, was attached. By this means a satisfactory job of the boring was effected."

Diluted Paraffin for -Cleaning.

[ibu3] H.L." (Ryde, I. of AV.) writes —"I think the following remarksniay be useful for the 'Drivers, Mechanics, and Foremen's' columns :—Owing to the scarcity and high price of paraffin, it has been necessary for us to eConornise with paraffin for cleaning purposes. When cleaning., parts after they have been taken .down for overhaul, or cleaning engine easing, or other parts in the chassis, I have found tha,t the best way is to first scrape off as much of the clotted oil, and mud as possible With a, table-knife, then brush the parts with a, wire brush. After the parts. have been cleaned ,in this way as Much as possible. mix up the

following proportions of paraffin and water to the quantity you require for your tank or cleaning pan, say half-gallon of paraffin to two gallons of water.

"This mixture r have found has given practically as good'results as pure paraffin. Then for wiping we-use newspapers,which is a great saving of rags or waste. On the finished job there is practically no sign, of water."

Home-made Wheel-set for Fords.

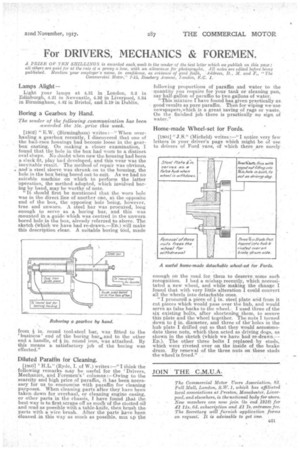

[1804] "JS." (Mirfield) writes :—" I notice very few letters in your driver's page which might be of use to drivers of Ford vans, of which there are surely enough on the road for them to deserve some such recognition. I had a mishap recently, which necessitated a. new wheel, and while making the change I found that with very little alteration I could convert all the wheels into detachable ones.

"I procured a piece of in. steel plate and from it cut pieces which would pass over the hub, and would serve as false backs to the wheel. I used three of the six existing bolts, after shortening them, to secure this plate and the wheel together. The nuts I turned down to in. diameter, and three of the holes in the hub plate I drilled out so that they would accommodate these nuts, which then acted as driving dogs, as shown in the sketch (which we have had re-drawn.---En.). The other three bolts I replaced by studs, which were riveted over on the inside of the brake drum. By renewal of the three nuts on these studs the wheel is freed."