London' s New Motorbus Regulations.

Page 9

Page 23

Page 25

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

[Proprietors before entering into Contracts for new types of Motor Omnibuses would do well to send the drawings to New Scotland Yard for approval as to type.] NOTICE TO PROPRIETORS AS TO CONDITIONS FOR OBTAINING A CERTIFICATE. OF FITNESS FOR MOT9R OMNIBUSES.* Carriages must be submitted for inspection in a thoroughly good condition, and no carriage will be certified fit for public use unless it is newly painted and varnished. The following conditions must also be strictly complied with :

1. Stage Carriages propelled by mechanical means, and subject to the Light Locomotives Act (59 and 60 Vict., Cap. 36) and Motor Car Act (3 Edwd. VII., Cap. 36), must comply with the requirements of those or any subsequent Acts, and of the Orders of the Local Government Board made in pursuance thereof.

2. Each new type of motorcar intended for licensing must be presented at New Scotland Yard for inspection. The proprietor must at the same time produce the certificate of registration, and one from the maker, stating the machinery to be safe and in every way fit for use in a public carriage.

if, after inspection, the car is approved, such approval may extend to all cars of that description, and cars of that type need not be again presented at New Scotland Yard ; but may be taken to the usual passing station, provided a certificate from the maker is submitted with each car for licensing, stating that it is in every respect similar to the type already approved.

A certificate from the proprietor, stating there has been no • alteration in the design of the machinery since the previous inspection and date covered by the maker's certificate, must be presented with each car submitted for renewal of license.

Should an alteration be made, the same course may be required as for a first inspection.

Should it be deemed necessary, an expert will be employed to advise on the subject. The fee for the expert examination must be deposited by the proprietor with the Commissioner, which fee will be returned if the car is passed without alteration being required.

3. When making application for the carriage to be inspected, the proprietor must specify the route or routes upon which he intends to ply, and these may not be departed from except after due notice has been given to the Commissioner of Police.

(NoTE.-Nothing in this Regulation shall be taken to prohibit a proprietor changing the route as often as he chooses, provided the carriage has been certified to be fit for such route.)

4. The following measurements and requirements for an omnibus with top-deck seats must be adhered to, and the number of passengers to be provided for on such vehicles must in no case exceed sixteen inside and eighteen outside: Chassis, length-Not to exceed 20ft. ; but if the platform is carried on the frame the total length may he 23ft.

Chassis clearance-The front axle and all the underworks of the car inside the pivots of the front axle (which must be placed as near as possible to the wheels), as far back at least as the rear axle, must clear the ground at least 10in, when the car is fully loaded, allowing half an inch in addition for new tyres to provide for wear.

Chassis, wheelbase-Should not exceed 141t. 6in., and it should in all cases be so proportioned that skidding or other improper movements shall be as far as possible avoided. (Nom-The Commissioner reserves the right, even after a car has been passed, if it is found to be apt to skid unduly, to issue a notice on the proprietor not to use, and may refuse to license again until the defects have been remedied.)

Chassis, springs-The springs must be properly hung, of sufficient strength, and flexibility, to meet all purposes which may be required of them. Those springs carrying the load must he attached to, er bear upon the back axle, as near to the wheels as possible the distance between the outsides of the rear springs shall not be less than 45in. The front springs must be as wide apart as possible, but not less than 3F.1in. from outside to outside. Where a cross spring is used, it must be so applied that it shall not cause or increase side sway.

Chassis, wheel track-Centre of, which must not be less in front than in rear, must not be iess than bit. 6in.

Body, inside-Minimum height to centre of roof from floor battens 5ft. IOin., maximum 6ft, Body, outside-Maximum height, from ground to spring of roof, 9ft. Maximum height, from ground to centre of roof, Oft. 3in.

Body camber-The camber should not be more than 3in., but may, if the proprietor so desires, be made up to but not exceeding bin., provided the outside of roof is so constructed as to give

*Words in italics are those introduced since the September draft was circulated. Those within brackets, and printed in small capitals, are the words now omitted from that draft. No notice has been taken by us of mere improvements in diction.-En. an equivalent in all respects to a 3in. camber, and the height from the ground is not in any way =creased.

Body guard rails-The side guard rails must be at least 3ft. from top of roof battens at the side and 18in. above the seats, measured from the highest part. The front and back guard rails must be at least 3ft. 3in., measured from the top of roof battens, at e.ach point following the roof camber.

Body, inside-The width between seat backs must not be less than 56in. when the seats are placed lengthwise.

Body, outside-The space from off hind roof seat, or any projection thereon other than a commode rail not exceeding 3m. to back guard rail, must not be less than 26in.

Body steps-Where more than one is used the staircase handrail must reach to the centre step, and be properly and rigidly fixed.

Body, length of platform-Not less than 36in. nor more than 42in.

The total overall length of the chassis and body must in no case exceed 23ft., nor the extreme breadth be greater than 7ft. 2in.

NOTE.-Omnibuses which carry a less number of passengers than thirty to be made in proportion to the foregoing measurements as to length ; but the number of passengers carried upon the outside must not be in greater proportion than seven to six inside.

3. No canopy or other similar superstructure will be permitted on the rcof of omnibuses constructed to carry passengers on the top deck.

6. Each carriage must be fitted with at least two independent brakes, of sufficient strength so that either of them shall be capable of stopping and holding the carriage under all conditions. They must also, where necessary, be fitted with a cornpznsaling device.

NOTE.-The maintenance of the brakes in perfect order is of the utmost importance, and this will at all times be insisted upon. They will at any time be subject to inspection by Police.

7. The brakes should, as far as possible, be so affixed as to be capable of easy adjustment, and at least one must be so made as to be applied by the foot of the driver. No two brakes which operate upon the same part will be considered as 'independent," and at least one should act directly upon the road wheels without any connection with the propelling gears.

S. Stage carriages which are intended to ply upon routes which have long or steep hills, will be subject tc a special test, and additional brakes may be required.

9. All brake and steering connections secured with bolts must have such bolts fitted with nuts, which latter must be locked or pinned. These parts mill be subject to inspection at any lime.

10. Each car must be capable .of being readily steered and able to turn a corner without unduly interfering with other traffic.

11. The steering arms, etc., must be of sufficient strength, and as far as possible protected from damage by collision.

12. All omnibuses must be so geared that their normal highest ipeed shall not be in excess of the maximum laid down in the Local Government Roard Order, viz., twelve miles an hour.

13. 'rhe machinery must be so constructed that no undue noise or vibration is caused, and the maintenance of the carriage in this condition will be strictly enforced.

14. All parts connected by bolts, or studs and nuts, subject to severe vibration, must be fastened by lock nuts or by nuts and approved spring or lock nut washers, to prevent their working loose and causing a rattling noise, and any carriage with lamp brackets, mudguard brackets, or other fittings loose and likely to cause unnecessary noise, will be regarded as unfit for public service. 15. Effective means must be adopted for preventing the heat of the motor or of the exhaust pipe connections from injuriously affecting other parts of the carriage or the comfort of the passengers. 16. All wires carrying electric current must be properly insulated and protected from injury, and so placed that they cannot be the cause of danger.

17. Tanks for petrol or other liquid fuel must be made of suitable material, properly constructed, and of sufficient strength. They should be so placed that any overflow shall not accumulate on woodwork, or where it can be readily ignited. The filling nozzle or inlet for the petrol or other liquid fuel should, where possible, be brought to the outside of the body.

18. Carburetters, unless they are suitably encased or screened, must not be placed in close proximity to magnetos, or to connections of wires carrying electric current.

19. The outlet from the silenc:r must not be so placed as to project the exhaust directly on to the roadway, or be so placed, or so directed as to alarm horses immediately behind the vehicle.

20. When a guard or tray is fixed underneath, it must be so constructed that any overflow of petrol from the carburetter [IS CARRIED DIRECTLY AWAY AND] shall not be retained in the tray. (Continued on page 249.) Metal.

There is very little to be said of the metals per se which are on exhibition at the Show. About the only stand wholly devoted to steel is that of W. T. FLATHER, LIMITED, the Standard Steel Works, Love Street, Sheffield (Stand No. 224), which company exhibits many pieces to show the quality of its steel, and the excellency and evenness of its case-hardening with the" Cbas "brand of steel. The good results obtained are exceedingly well shown in a series of torsion tests. This metal is extensively used for gears of all classes, and examples of forgings are shown. For axles, the company makes a special nickel steel, whilst a considerable trade has been done in valves made of a 25 per cent. nickel steel having a tensile strength of 46 tons per square inch. It is clear that this company intends to cater for many manufacturing needs.

Aluminium castings, of all types, are, of course, on view on all cars shown, whilst WILT.ANS AND ROBINSON, LIMITED, of Rugby (Stand No. 202), to whose display we referred last week, has very clean castings of intricate design on its stall. WILLIAM MILLS, LIMITED, of Sunderland and Birmingham (Stand No. 223), is a company which has made a speciality of aluminium and its uses on motors, and its exhibit is wholly devoted to this metal : it would seem to be impossible that any prospective purchaser could not find, here, some shape approximating to what he required.

Dovv.R, Limimu, of Northampton (Stand No. 254), shows steering wheels, of various designs, with ribbed grip covered with " Exonite." The ribbing is, sometimes, continued right round the tube of the handle, whilst, in other cases, it is on the underside only. This latter gives a very smart appearance, as the top can be kept clean and smart with a minimum of trouble. One wheel which seemed to us to be particularly suitable for motorbuses was made of tubular steel, in two parts, to the cover of which a malleable iron centre was riveted before the top two halves of the tube were lap-joined. The whole is, afterwards, covered with "Exonite," the under half being ribbed to give a strong grip, as in the illustration. The users of commercial vehicles of the Lighter type, such as delivery vans, will find much of interest in the tire section. The latest novelties in tires are exhibited, but, undoubtedly, there

is a strong ,cy towards standardisation, and there is not much distincdon between the exhibits of the various firms competing for the buyer's favour in this quarter. Pneumatic tires are used very largely on the smaller delivery vans, because the smooth travelling saves extra care in packing the contents, whilst reducing the wear and tear of the vehicle itself. For that reason, we have drawn attention to the various types of pneumatic tires that are likely to be of use to our readers, and have, at the same time, mentioned all exhibits of the heavier class, particularly solid tires, since they are more especially within our province.

Pneumatic Tires.

The requirements of the touring car in the matter of tires are very similar to those of the light delivery van. Both these vehicles travel at moderate rates of speed, and carry considerable loads. Tires that have been more especially designed for touring cars are, therefore, of some interest to van owners. In order to study their relative suitability, it is interesting to compare the sections adopted by the different tire makers. These sections do not vary to a great extent, but the differences show that the perfect tire has not yet been completely evolved. The system of fixing is, almost universally, that of the beaded edge, which fits into grooves in the rim, but the COLLIER TIRE COMPANY, LIM tTED, of 127, Long Acre, W.C., still markets a tire to he mechanically attached, which, it is urged, is far more satisfactory for large and heavy cars. The great point in favour

TIRES.

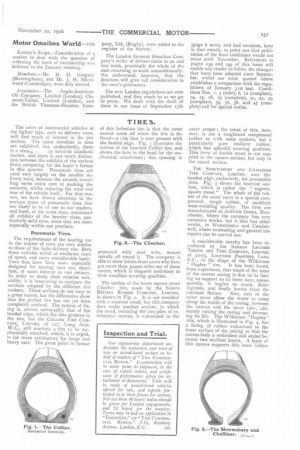

of this bolted-on tire is that the cover cannot come off when the tire is deflated—a risk that is ever present with the beaded edge. Fig. / illustrates the section of the heaviest Collier tire, and shows the hole in the bead for the mechanical attachment ; this opening is protected with steel wire, wound spirally all round it. The company is able to show letters from users who have got more than 30,000 miles out of these covers, which is eloquent testimony to their excellent wearing qualities.

The section of the heavy square tread Clincher tire, made by the NoRTH BRITISII RUBBER COMPANY, 1.IM1TRD, is shown in Fig. 2. It is not moulded with a separate tread, but this company does make another section, in which the tread, including the two plies of reinforcimr canvas, is vulcanised to the

cover proper; the tread of this, however, is not a toughened compressed rubber as with some makers, but a particularly pure resilient rubber, which has splendid wearing qualities. This form of double tread is not supplied in the square section., but only in the round section.

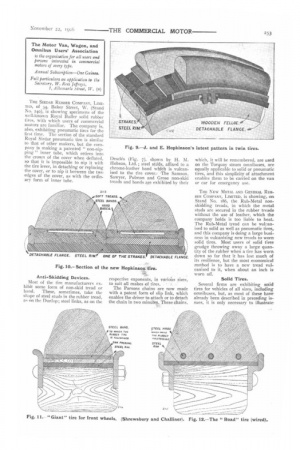

THE SHREWSBURY AND CHALLINER TIRE COMPANY, LIMITED, Uses the beaded edge, exclusively, for pneumatic tires. Fig. 3 shows the heaviest section, which is called the " tosmm. square tread." The whole of the rubber of the outer cover is a special compressed, tough rubber, of excellent wear-resisting quality. The tires are manufactured at Ardwick Green, Manchester, where the company has very extensive works, but it also has other works, in Westminster and Camberwell, where re-treading and general tire repairs can be carried out.

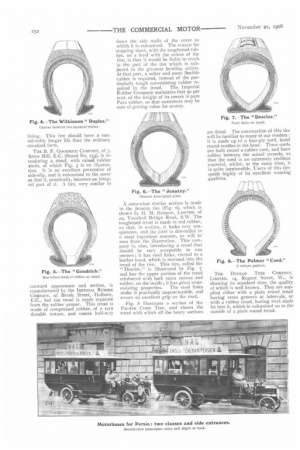

A considerable novelty has been introduced by the SAMSON LEATHER TREADS AND TYRE COMPANY, LIMITED, of 22-23, Laurence Pountney Lane, B.C., in the shape of the Wilkinson

" Duplex " tire. It has been found, from experience, that much of the wear of the canvas casing is due to its having no support on its inner face; consequently, it begins to crack, disintegrates, and finally bursts from the constant flexion. Also, cuts in the outer cover allow the water to creep along the inside of the casing, between the canvas and the inner tube, ultimately rotting the casing and decreasing its life. The Wilkinson "Duplex" tire, which is illustrated in Fig. 4, has a lining of rubber vulcanised to the inner surface of the casing so that the canvas body is embedded and sealed between two resilient layers. A layer of thin canvas supports this inner rubber Fig. 4.—The Wilkinson" Duplex." Canvas betaTen two layers of rubber.

lining. This tire should have a considerably longer life than the ordinary standard form.

THE B. F. GOODRICH COMPANY, of 7, Snow Hill, E.C. (Stand No. 233), is introducing a tread, with raised rubber studs, of which Fig. 5 is an illustration,. It is an excellent preventive of side-slip, and is vulcanised to the cover so that it, practically, becomes an integral part of it. A tire, very similar in

outward appearance and section, is manufactured by the IMPERIAL RUBBER COMPANY, of Brook Street, Holborn, E.C., but the tread is made separate from the rubber proper. This tread is made of compressed rubber, of a very durable nature, and comes half-way down the side walls of the cover to which it is vulcanised. The reason for stopping short, with the toughened rubber, on a level with the centre of the tire, is that it would be liable to crack in the part of the tire which is subjected to the greatest bending action. At that part, a softer and more flexible rubber is required, instead of the particularly tough cut-resisting rubber re quired in the tread. The Imperial Rubber Company maintains that 90 per cent. of the weight of its covers is pure Para rubber, so that customers may be sure of getting value for money.

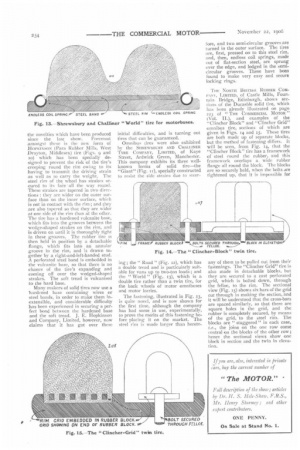

A somewhat similar section is made in the Jenatzy tire (Fig. 6), which is shown by H. M. HOBSON, LIMITED, of 29, Vauxhall Bridge Road, S.W. The toughened tread is made in red rubber, so that, in section, it looks very conspicuous, and the joint is dovetailed in a most ingenious manner, as will be seen from the illustration. This company is, also, introducing a tread that should be very acceptable to van owners; it has steel links, riveted to a leather band, which is recessed into the tread of the tire. This tire, called the " Desclee," is illustrated in. Fig. 7 and has the upper portion, of the tread reinforced with both extra canvas and rubber, on the inside; it has great wear

resisting properties. The steel links make it practically unpuncturable, and secure an excellent grip on the road.

Fig. 8 illustrates a section of the PALMER CORD TIRE, and shows the tread with which all the heavy sections are fitted. The construction of this tire will be familiar to many of our readers : it is made up of a four-ply cord, laced round needles in the bead. These cords are built round a rubber core, and have rubber between the actual strands, so that the cord is an. extremely resilient material, whilst, at the same time, it is quite inextensible. Users of this tire speak highly of its excellent wearing qualities.

THE DUNLOP TYRE COMPANY, LIMITED, 14, Regent Street, W., is showing its standard tires, the quality of which is well known. They are supplied either with a plain round tread having cross grooves at intervals, or with a rubber tread, having steel studs let into it, which is vulcanised on to the outside of a plain round tread. THE SIRDAR RUBBER COMPANY, LIMITED, of 34, Baker Street, W. (Stand No. 240), is showing specimens of the well-known Royal Buffer solid rubber tires, with which users of commercial motors are familiar. The company is, also, exhibiting pneumatic tires for the lirst time. The section of the standard Royal Sirdar pneumatic tire is similar to that of other makers, but the company is making a patented " non-nipping " inner tube, which retires into the crown of the cover when deflated, so that it is impossible to nip it with the tire lever, in detaching or replacing the cover, or to nip it between the two edges of the cover, as with the ordinarv form of inner tube.

Anti-Skidding Devices.

Most of the tire manufacturers exhibit some form of non-skid tread or band. These, sometimes, take the shape of steel studs in the rubber tread, as on the Dunlop; steel links, as on the Descles (Fig. 7), shown by H. M. Hobson, Ltd.; steel stUds, affixed to a chrome-leather band which is vulcanised to the tire cover. The Samson, Sawyer, Pulman and Grose non-skid treads and bands are exhibited by their

respective exponents, in varidus sizes, to suit all makes of tires. 3

The Parsons chains are now made with a patent form of slip link, which enables the driver to attach or to detach the chain in two minutes. These chains, which, it will be remembered, are used on the Torquay steam omnibuses, are equally applicable to solid or pneumatic tires, and this simplicity of attachment enables them to be carried on the van or car for emergency use.

THE NEW METAL AND GENERAL RUBBER COMPANY, LIMITED, is showing, on Stand No. I86, the Rub-Metal nonskidding treads, in which the metal, studs are secured in the rubber treads without the use of leather, which the company holds is too liable to heat. The Rub-Metal tread can be vulcanised to solid as well as pneumatic tires,. and this company is doing a large business in vulcanising new treads to worm solid tires. Most users of solid tires grudge throwing away a large quantity of the rubber when a tire has worn down so far that it has lost much of its resilience, but the most economical: method is to have a new tread vulcanised to it, when about an inch is worn off.

Solid Tires.

Several firms are exhibiting solid tires for vehicles of all sizes, including omnibuses, but, as most of these havealready been described in preceding issues, it is only necessary to illustrate

the novelties which have been produced since the last show. Foremost amongst these is the new form of Hot,KiNsoN (Para Rubber Mills, West Drayton, Middlesex) tire (Figs. 9 and To) which has been specially designed to prevent the risk of the tire's creeping round the rim owing to its having to transmit the driving strain as well as to carry the weight. The steel rim of the wheel has strakes secured to its faCe all the way round. These strakes are tapered in two directions : they are wider on the outer surface than on the inner surface, whirh is not in contact with the rim ; and they are also tapered so that they are wider at one side of the rim than at the other. The tire has a hardened vulcanite base, which fits into the grooves between the wedge-shaped strakes on the rim, and is driven on until it is thoroughly tight in these grooves. The rubber tire is then held in position by a detachable flange, which fits into an annular groove in the rim, and is drawn together by a right-and-left-handed stud. A perforated steel band is embedded in the vulcanite base, so that there is no chance of the tire's expanding and coming off over the wedged-shaped strakes. The soft tread is vulcanised to the hard base.

Many makers of solid tires now use a hardened base containing wires or steel bands, in order to make them inextensible, and considerable difficulty has been experienced in securing a perfect bond between the hardened base and the soft tread. J. E. Hopkinson and Company, Limited, however, now claims that it has got over these

initial difficulties, and is turning out tires that can be guaranteed.

Omnibus tires were also exhibited by the SIIREWSBURY AND CHALLINER TYRE COMPANY, LIMITED, Of Kaye Street, Ardwick Green, Manchester. This company exhibits its three wellknown forms of solid tire—the "Giant" (Fig. r), specially constructed to resist the side strains due to steer

ing ; the Road "(Fig. 12), which has a double tread and is particularly suitable for vans up to two-ton loads ; and the "'World " (Fig. 13), which is a double tire rather than a twin tire, for the back wheels of motor omnibuses and motor lorries.

The fastening, illustrated in Fig. 13, is quite novel, and is now shown for the first time, although the company has had some in use, experimentally, to prove the merits of this fastening before placing it on the market. The steel rim is made larger than hereto

fore, and two semi-circular grooves are turned in the outer surface. The tires are, first, pressed on to this steel rim, and, then, endless coil springs, made out of flat-section steel, are sprung over the edge, and lodged in the semicircular grooves. These have been found to make very easy and secure locking rings.

NoRitt Burrisit RUBBER COMPANY, LIMITED, Of Castle Mills, FOLIIIrain Bridge, Edinburgh, shows sections of the Ducasble solid tire, which has been already illustrated on page 223 Of "THE COMMERCIAL MOTOR" ( Vol. II.), and examples of the "Clincher Block" and "Clincher Grid" omnibus tire, sections of which are given in Figs. 14 and 15. These tires are both made up of separate blocks, but the method of fastening differs. It will be seen, from Fig. 14, that the "Clincher Block" tire has a framework of steel round the rubber, and this framework overlaps a, wide rubber flange all round the block. The blocks are so securely held, when the bolts are tightened up, that it is impossible for any of them to be pulled out from their fastenings. The "Clincher Grid" tire is also made in detachable blocks, but they are secured to a cast perforated grid, which is bolted down, through the felloe, to the rim. The sectional view (Fig. 15) shows six bars of the grid cut through in making the section, and it will be understood that the cross-bars are spaced similarly, so that there are square holes in the grid, and the rubber is completely secured, by means of the grid, to the steel rim. The blocks are " staggered" in each case, i.e., the joins on the one row come central on the blocks of the other row ; hence the sectional views show one block in section and the twin in elevation.