Drawbars are no drag

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

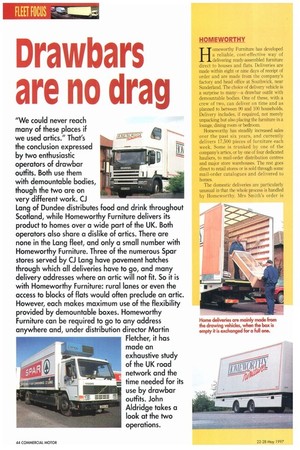

"We could never reach many of these places if we used artics." That's the conclusion expressed by two enthusiastic operators of drawbar outfits. Both use them with demountable bodies, though the two are on very different work. CJ Lang of Dundee distributes food and drink throughout Scotland, while Homeworthy Furniture delivers its product to homes over a wide part of the UK. Both operators also share a dislike of artics. There are none in the Lang fleet, and only a small number with Homeworthy Furniture. Three of the numerous Spar stores served by CJ Icing have pavement hatches through which all deliveries have to go, and many delivery addresses where an artic will not fit. So it is with Homeworthy Furniture: rural lanes or even the access to blocks of flats would often preclude an artic. However, each makes maximum use of the flexibility provided by demountable boxes. Homeworthy Furniture can be required to go to any address anywhere and, under distribution director Martin Fletcher, it has made an exhaustive study of the UK road network and the time needed for its use by drawbar outfits. John Aldridge takes a look at the two operations. HOME WORTHY Homeworthy Furniture has developed a reliable, cost-effective way of delivering ready-assembled furniture direct to houses and flats. Deliveries are made within eight or nine days of receipt of order and are made from the company's factory and head office at Southwick, near Sunderland. The choice of delivery vehicle is a surprise to many—a drawbar outfit with demountable bodies. One of these, with a crew of two, can deliver on time and as planned to between 90 and 100 households. Delivery includes, if required, not merely unpacking but also placing the furniture in a lounge, dining room or bedroom.

Homeworthy has steadily increased sales over the past six years, and currently delivers 17,500 pieces of furniture each week. Some is trunked by one of the company's artics, or by one of four dedicated hauliers, to mail-order distribution centres and major store warehouses. The rest goes direct to retail stores or is sold through some mail-order catalogues and delivered to homes.

The domestic deliveries are particularly unusual in that the whole process is handled by Homeworthy. Mrs Smith's order is controlled from the start in Sunderland. The order is not just acknowledged, the householder is sent a pre-advice letter with a reference and day of delivery On one mailorder contract the customer is phoned rather than written. Finally, the delivery team will phone a couple of hours before the actual drop to confirm that they are on their way and give a specific time of arrival.

A twightlight office shift is worked from 17:00 to 21:00hrs to contact customers who are not at home in the day, and there is a further Saturday morning shift to contact those not at home in the evenings! Some orders are vague about home addresses, and the correct postcode is essential for Homeworthy's system.

All orders are handled on the paperless EDI (electronic data interchange) system, and will be in the planning cycle within one working day. Homeworthy does not build for stock, so integral parts of handling the order include nominating the loading aisle seven or eight days ahead. In what on the one hand seems surprising, and on the other totally logical, is that the furniture is manufactured the day it is to be loaded on to a vehicle. So the delivery schedule is worked out first on receipt of order and then the manufacturing programme follows. This avoids any double handling, and at the same time eliminates the need for what could be an enormous warehouse.

There are now 35 drawbar outfits in the fleet, plus 12 artics and 33 semi-trailers. All carry demountable boxes, giving a total fleet of 254 items, It is the domestic delivery outfits that are the most impressive. Drawing units are mainly Scania, including latest Scania 94Ds with 260hp engines. Not only do they have the full Scania sleeper cab, they also have a sleeper pod. When away from base, often for two nights at a time,

the driver sleeps on the spacious cab bunk, while the mate sleeps in the pod.

Drivers, or potential drivers, join as a mate or second man, and this gets them au fait with company procedures, documentation, and customer relations. Only four drivers have left the company in the past eight years, so the system is successful. Even after passing their test, drivers initially continue as second men. They also receive training from the Institute of Advanced Motorists.

This year's deliveries of new vehicles included 10 Scania 94Ds, 10 trailers and 40 demountable bodies. Wheelbase Engineering of Blackburn built the trailers while the roof pods and 40 demountable bodies came from Marsden VanPlan. Homeworthy specs full air suspension on vehicles and trailers, and developments for the latest deliveries include chassis modifications and low-profile tyres, which has reduced overall height from the previous 4.42m to 4.1m. Access steps are provided on vehicle and trailer and there is a retractable tailgate. Self-releasing hitches have been specified on the latest deliveries to avoid the driver having to crouch under the coupling.

Crews on home shopping deliveries work an unusual three weeks on, one week off system. In the first two weeks of the cycle they work on Sunday to Friday, then Monday to Saturday in the third. This gives a wide delivery window, and also effectively gets five weeks' work out of an outfit in four weeks.

An enormous amount

of .CF444,4\\' work by Homeworthy

went into developing the routeing and scheduling system to accommodate

multi-drop, multi-day drawbar combination operations, using Paragon 2 software. Off motorways and dual carriageways drawbar outfits are subject to severe speed restrictions, and Homeworthy studies 20,000 actual miles of road before developing its own program with 10 different road speeds all worked from the grid reference of the customer's postcode.

The drawbars do not trundle round to individual homes. They are used to give the maximum cube on stem mileage—furniture takes up a lot of space. The drawbars are parked at convenient locations and the prime mover delivers the loads on its demountable boxes first, before returning to exchange its empty boxes and pick up the loaded ones from the trailer. All the boxes are fitted with an elaborate security system.

The scheduling system already gives precise timings for individual deliveries. Scheduled and actual times are closely monitored, and the next step is likely to be to give customers not just an am or pm indication when their order is acknowledged, but a much more precise time.

C J LANG

Rigids, rigids plus drawbar trailers, all with tail-lifts and demountable boxes provide enormous flexibility of operation for specialist food and drink supplier CJ Lang & Son of Dundee. It is in both the wholesale and retail sides of the business, owns six cash-and-carry stores, plus a number of Spar stores, and supplies almost 300 Spar stores throughout Scotland.

Some 90% of the population in Scotland is • said to be within a 90-minute drive of Dundee, but CJ Lang's coverage includes Spar stores in remote parts, including Wick in the far north, and the remote island of Iona. The level of service provided ranges from daily to at least once weekly, the only exception being Iona, serviced fortnightly in winter. The vehicle for Iona—a rigid—goes by ferry from Oban to Craignure, on the Isle of Mull (fare £280), then drives across Mull before taking a ferry to Iona (fare £75).

The demountable bodies are mainly conventional boxes, but there are also curtainsiders, fridges and dual-temperature boxes.

Mixing and matching

The fleet totals 45, all rigids, but with about half hauling drawbar trailers. The potential for mixing and matching is unlimited: for example, a fridge box on the rigid hauling an ambient box on the drawbar. With drawbars the usual method of operation is to begin with deliveries off the trailer, which is dropped when empty and the drawing vehicle then continues alone. The curtainsided boxes are used for deliveries to cash-and-carry stores which have forklift trucks for unloading.

The fleet is unusual in operating no artics. But its move into drawbars came about in an unusual way. At the height of the last recession Lang, along with many other operators, had to contend with delays of up to six months on deliveries of new vehicles. But two major drawbar operators, Schreiber and M.FI, were at the time re-equipping and their vehicles and trailers came on to the secondhand market. CJ Lang bought some, refurbished them and at the same time had the height of the bodies reduced by 0.6m.

The purchase gave a quick entry to drawbar operation at an economic price. Most of the rigids have since been replaced, but many drawbar trailers remain: they only cover about half the mileage of the drawing units. Since then the company has resumed buying new, mainly Scania and Volvo rigids, with demountable bodies and drawbar trailers all by Cartwrights of Altrincham. Cartwrights also builds the trailer chassis, and Ross & Bonnyman tail-lifts are fitted.

Multi-drop work

The latest rigids are three axle, to avoid potential problems of axle overloading on multi-drop work. The problem is largely seasonal: a good summer and the fleet will be carrying considerable quantities of soft drinks (and beers and lagers) and a full roll cage is quite heavy. The company has its own weighbridge over which all vehicles pass before leaving.

The latest deliveries include demountable fridge boxes, of which more are on order. The boxes have to be carried on the drawing vehicle and have Frigoblock systems worked off a vehicle-mounted alternator— connection is via a simple plug. The interior is split one-third, two-thirds lengthwise to allow a mix of frozen and either ambient or chilled goods. Total temperature range is

from -25°C to +3°C, and the chilled or ambient compartment is fitted with a heater to raise temperature to plus 3°C on frosty days.

Most drivers keep to the same vehicle, but some are double shifted. The transport operation handles the usual mix of food, tobacco and alcoholic drinks, mainly in roll cages. Operations at the Dundee warehouses begin at noon on Sundays and work continuously through to after lunchtime the following Saturday.

The first vehicles out leave for Inverness at 23:00hrs and are followed by a main delivery exodus at 05:00hrs, with a few more leaving at 06:00-07:00hrs. Some vehicles on shorter runs come back for a second delivery run.

CJ Lang first went into demountable drawbars when it needed extra capacity quickly after taking over another business. In less than five years it has proved the value of drawbars: "go over 50 miles and you're in business with a trailer," says transport manager Gary Scott.