DESIGNERS throughout the world are hard at work developing power

Page 86

Page 87

If you've noticed an error in this article please click here to report it so we can fix it.

units to meet the long-term energy requirements of both the customer and the legislator.

That fact was certainly evident at a recent conference organised by the AE group of companies when a paper entitled "A Preview of new prime movers" was presented by D. A Parker and R. H. Slee of AE Developments Ltd.

Different types of engine and the possibility of using alternative fuels came under close scrutiny.

The cost of production of various fuels is shown in the accompanying table. As the extraction of "conventional" fuels becomes more difficult and thus more expensive, there will be an increased incentive to use deposits hitherto passed over as unecomomic (eg, oil shale) and, in parallel, to seek alternative fuels — preferably liquids — which are likely to become cost effective.

Extraction of oil from shale is currently underway in the USA, yielding 10,000 barrels per day, while the extraction of oil from tar sands by the injection of steam is progressing both in Canada and the USA.

An example of the alternative approach is to burn coal directly in internal combustion engines, either as a coal/oil slurry or as a powder. Experiments by Sulzer and MAN with diesel engines operating coal dust (which has a calorific value 55 per cent that of oil) have shown considerable promise.

Consideration of the use of coal as a fuel for Stirling engines has shown that at powers over 400 horsepower, the running costs are competitive with current diesel engines. AE suggests that because of the large reserves of coal its importance as a transport fuel is likely to increase, although research suggests slow combustion and wear from abrasion.

Liquefied petroleum gas (or strictly speaking gases) has the advantage of being a clean burning fuel with low emissions and light engine deposits. The major constituent is butane with the addition of propane and propylene. Butane has an octane rating of 89 compared to the 85 of propylene.

The proportions of various hpg constituents are liable to vary, which can lead to "knock" problems and piston crown burning, and this is particularly likely where the intake manifold is unsuited to gaseous fuel. GM, Ford, and International Harvester now offer commercial vehicle engines adapted for hog.

AE also considers compressed natural gas (CNG) to be suitable for a vehicle, albeit with reservations. Its principal constituent is methane which has an octane number of 102 but it needs to be stored under high pressure which limits the vehicle range. Although liquefaction is possible, this requires expensive cryogenic (-162°C or -260°F) handling and storage facilities.

Hydrogen, with a calorific value over twice that of petrol, has long been attractive as a fuel, but AE suggests that much work is required before it can be considered a commercially viable fuel.

Again, it poses special storage problems. Although hydrogen may be stored as a compressed gas, as a cryogenic liquid or as a hydride (usually magnesium hydride), the combined weights of the fuel and carrier are respectively 15 times, 2.4 times and 4.6 times that of the energy equivalent petrol.

Recent experiments in the UK on the bleeding of hydrogen gas into the inlet manifolds of sparkignition engines show considerable promise according to AE. The rate of hydrogen admission is sufficient to cater wholly for the idle condition; thereafter, increasing levels of power are obtained from petrol via the carburetter in the normal manner. The idle and part-load fuel economy is claimed to be improved almost to the level of a diesel engine.

An alternative way of using hydrogen for road transport is by a fuel cell/electric system, an alternative feature of which is the high part load efficiency. However, AE admits that although reliability has been amply demonstrated by space exploration, the difficulties of hydrogen storage remain significant in more mundane applications.

THERMAL EFFICIENCY Since a large proportion of engine losses are thermal, it shold be possible to improve thi thermal efficiency significantly by preventing such losses reaching the exterior. In recent years there have been many attempts to use ceramics both tl insulate combustion chambers parts and to withstand the resulting higher operating temperatures.

AE claims that apart from eliminating external cooling requirements, insulation can only be of value if the energy diverted to the exhaust is recovered either by turbocharging or turbocompounding where the turbocharger is geared to the crankshft via a flexible coupling Cummins, for example, has been carrying out research along these lines and has achived an improvement in specific fuel consumption from 183 to 173 g/kWh (0.300 to 0.28f. lb/bhp).

The elimination of oil from thi engine is also a possibility usint ceramic rollers in the main and big end bearings. Insulation is also provided on the piston crown, the inner part of the heat and the upper part of the liner. II indirect injection engines, it can also extend to the precombustion chamber as shown in the diagram.

The adiabatic concept is beim investigated by many diesel manufacturers but it is still som way off, as is emphasised by ntimates of the probability of lot using some insulated .:omponents in production .4ngines before 1990.

Although most of the small liesel engines in current use are if the idi type, the nanufacturers are now nvestigating the change to iirect injection on the grounds )f fuel economy. The /olkswagen arrangement ;hewn here is typical of the iesign.

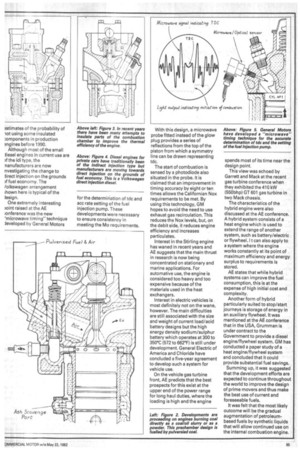

One extremely interesting mint raised at the AE :onference was the new 'microwave timing" technique leveloped by General Motors for the determination of tdc and acc rate setting of the fuel injection pump. These developments were necessary to ensure consistency in meeting the Mo requirements. With this design, a microwave probe fitted instead of the glow plug provides a series of reflections from the top of the piston from which a symmetry line can be drawn representing tdc.

The start of combustion is sensed by a photodiode also situated in the probe. It is claimed that an improvement in timing accuracy by eight or ten times allows the Californian Nox requirements to be met. By using this technology, GM hopes to avoid the need to use exhaust gas recirculation. This reduces the Nox levels, but, on the debit side, it reduces engine efficiency and increases particulates.

Interest in the Stirling engine has waned in recent years and AE suggests that the main thrust in research is now being concentrated on stationary and marine applications. For automative use, the engine is considered too heavy and too expensive because of the materials used in the heat exchangers.

Interest in electric vehicles is most definitely not on the wane, however. The main difficulties are still associated with the size and weight of current load/acid battery designs but the high energy density sodium/sulphur battery which operates at 300 to 350°C (572 to 662°F) is still under development. General Electric of America and Chloride have concluded a five-year agreement to develop such a system for vehicle use.

On the vehicle gas turbine front, AE predicts that the best prospects for this exist at the upper end of the power range for long haul duties, where the loading is high and the engine spends most of its time near the design point.

This view was echoed by Garrett and Mack at the recent gas turbine conference when they exhibited the 410 kW (550bhp) GT 601 gas turbine in two Mack chassis.

The characteristics of the hybrid engine were also discussed at the AE conference. A hybrid system consists of a heat engine which is used to extend the range of another system, such as battery/electric or flywheel. I t can also apply to a system where the engine works constantly at its point of maximum efficiency and energy surplus to requirements is stored.

AE states that while hybrid systems can improve the fuel consumption, this is at the expense of high initial cost and complexity.

Another form of hybrid particularly suited to stop/start journeys is storage of energy in an auxiliary flywheel. It was mentioned at the AE conference that in the USA, Grumman is under contract to the Government to provide a diesel engine/flywheel system. GM has conducted a paper study of a heat engine/flywheel system and concluded that it could provide substantial fuel savings. Summing up, it was suggested that the development efforts are expected to continue throughout the world to improve the design of prime movers and thus make the best use of current and foreseeable fuels.

It was felt that the most likely outcome will be the gradual augmentation of petroleumbased fuels by synthetic liquids that will allow continued use on the internal combustion engine.