Special Tipper for Concrete Distribution

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

THE use in this country of the Belgian-made S.G.M.E. wet concrete distributor enables the speed of concrete laying to be greatly increased, but the characteristics of the machine create difficulties with regard to hopper filling from the standard type of tipping vehicle.

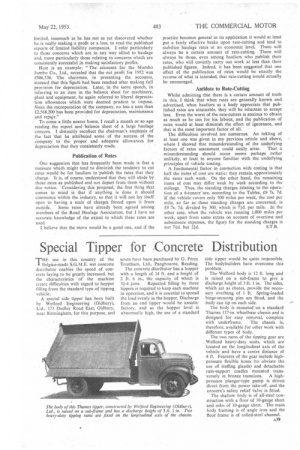

A special side tipper has been built by Welford Engineering (Oldbury), Ltd., 173 Dudley Read East, Oldbury, near Birmingham, for this purpose, and seven have been purchased by G. Percy Trentham, Ltd., Pangbourne, Reading.

The concrete distributor has a hopper with a length of 14 ft. and a height of 2 ft. 6 in., the capacity of which is 34--4 ,tons. Repeated filling by three tippers is required to keep each machine in operation, and it is essential to spread the load evenly in the hopper. Discharge from an end tipper would be unsatisfactory, and as the hopper level is abnormally high, the use of a standard side tipper would be quite impossible. The bodybuilders have overcome this problem.

The Welford body is 12 ft. long and is raised on a sub-frame to give a discharge height of 3 ft. 1 in. The sides, which act as chutes, provide the necessary overhang of 1 ft. Spring-loaded hinge-securing pins are fitted, and the .body can tip on each side.

The body is mounted on a standard Thames 157-in, wheelbase chassis and is designed for easy removal, complete with underframe. The chassis is, therefore, available for other work with different types of body.

The two rams of the tipping gear are Welford heavy-duty units, which are located on the longitudinal axis of the vehicle and have a centre distance of 4 ft. Features of the gear include highpressure flexible hoses (to obviate the use of stuffing glands) and detachable ram-support cradles mounted transversely in bronze trunnions. A highpressure plunger-type pump is driven direct from the power take-off, and the concern's safety relief valve is fitted.

The shallow body is of all-steel construction with a floor of 10-gauge sheet and sides of 10-gauge sheet. The main body framing is of angle iron and the floor frame is of rolled-steel channel.