MODERN METHODS MAIN N TRADITION

Page 42

Page 43

Page 44

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Efficient Techniques Employed in the Transport System of John Barker and Co., Ltd., Enhance Service to Customers, Yet Do NorDetract from the influence of the Personal Element

By Alan Smith

pERSONAL service to a customer means nothing if it is not ' accompanied by efficiency: equally, efficiency is not fully appreciated if the personal element is absent. The two ideals seem at first sight to arise from conflicting origins—efficiency from systematic technique, personal service from tradition. Notwithstanding the introduction of successive improvements in internal economy during the past 80 years, tradition has been retained by John Barker and Co., Ltd., Kensington High Street, London, W.8. This harmony is reflected by the company's road transport fleet.

Traditional influences are apparent in the conservative but distinctive livery of the vans, the courtesy of the drivers and delivery porters, and the team spirit of the • entire transport staff, many of whom have spent their whole working lives with the company. Efficiency results from the application of intelligent methods of dispatch and fleet management, the liberal employment of labour-saving equipment in the maintenance workshops, and an overall system of costing.

Six in One

John Barker and Co., Ltd., run the shop in Kensington bearing their own name and the adjacent stores of Derry and Toms, Pontings, and Ladymere. The first three sell drapery, general goods and furniture, whilst Ladymere, as the name implies, cater solely for women's requirements. In addition, the Barker store has a flourishing food section. The Zeeta chain of bakerypastryeook shops and restaurants also comes under the company's control, as does the drapery and furniture store of Gosling's at Richmond, Surrey.

The combined fleet of vehicles is not divided departmentally to correspond with each individual house, but with the categories into which the varieties of traffic from each establishment fall. This, of course, is a logical organization for a combine. Vehicles are allotted to the delivery of furniture, drapery, hardware and food, and the requirements of the Zeeta shops. Pantechnicons under B licences are attached to the furniture-removal department and are based at the depository in Cromwell Crescent. They are authorized for removals throughout Great Britain. ,

In respect of Zeeta., the .: distinct class. of traffic co--relates With the houSe name, and all the. special-type Dtt

vans supplying the widely scattered shops with bread and confectionery carry the same blue and gold livery. In the main class, however, vans bear the colours of Barker, Derry and Toms, Pontings or. Ladymere, although they eater for the traffic from all of these stores.

Most of the vans are 30 cwt. models. They carry mainly small packages, which although numerous, make up a light payload. The vans delivering furniture are of the 45-50 cwt. class with Luton bodies of about 700 cu. ft. capacity, whilst heavier vehicles are used for removals, the largest being a Bedford of 1,500 cu. ft. capacity based on an S.B. passenger chassis. The Zeeta fleet is composed mainly of Fordson 2-tonners and Bedford 3-tonners.

Pioneer operators of battery-electric vehicles, John Barker and Co., Ltd., used such vans even before the 1914-18 war, and, at the end of that conflict had a large fleet of electrics. Horsed vehicles were gradually superseded by these vans, the last of them being disposed of early in 1921. In 1939, many of the old Edison and Walker electrics were replaced by Metrovick 10-14-cwt. vans. Eighteen of these were destroyed early in 1941 in a fire started by a Getman incendiary bomb.

The fleet has recently been augmented by a number Of N.C.B. 1-ton vans incorporating many of the company's standard bodywork features, which include entry into the body from the cab for the delivery porter, let-down shelves, and roller shutters at the rear. Bedford C.A. vans, with slight adaptations to the manufacturer's specification, are used chiefly for special deliveries, such as floweo, or when purchases are required at short notice.

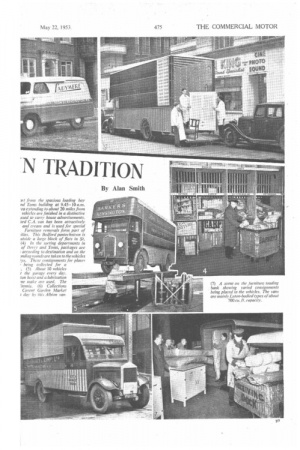

The carriage of fruit and vegetables from Covent Garden Market each morning is the work of an Albion 5-tonner, whilst Smithfield and Billingsgate are visited each day by a Dennis 40-50-cwt van with a special body. Transport operations are based upon the Derry and Toms building, in which there is a spacious modern loading bay accommodating facilities for handling furniture and general goods and the inward flow of goods for Derry and Toms. Returned traffic is dealt with in a special section of the bank where everything sent in by customers for repair, dry cleaning or exchange, together with empty containers, is handled. Each van driver, on return from a journey, reports there to hand in any goods brought back.

Next to the return dock is the section handling all dispatches to customers living outside of the company's free-delivery area. Postal collections are made frequently throughout the day from the western district office at Paddington. Railway vans collect from each of the main London termini, and operators from all parts of the country regularly pick up furniture and household effects for distribution to Barker's more distant customers.

Dispatch System

Beneath this bay is a basement dispatch department in which drapery, hardware and food are sorted into rounds for delivery. Consignments are sent down from the various departments either ready for dispatch or to be packed in the nearby packing bay. Goods from the associated houses are brought in throughout the day by a battery-electric van.

This basement bay has two sections, one for drapery and the other for food and household goods. Around the partitions of each section are racks, each of which bears the name of a certain district. Goods are placed in these accordingly and on the days when vans serve the particular area, the packages are taken from the racks and sent up in the lifts to the loading bay in basket trolleys for transfer to the vehicles.

To indicate whether the deliveries are paid, account, or C.O.D., address labels of varied colours are used. A check is kept on every item by means of a flimsy top docket, a duplicate of the address label on each parcel being torn off in the sorting room and handled separately in the records office where the porters' delivery sheets are compiled. , So effective has this system proved against misdirection or loss, that during the Christmas rushes of each of the past few years, when some thousands of parcels were dealt with each day, not one package went astray.

The shopping-card system is used in most of the large stores, and Barker's are no exception. This enables a customer to buy -goods in departments throughout the store, having her purchases recorded as she proceeds, in the knowledge that all her goods will be delivered at the same time.

Loading begins at 8 a.m., the work being carried out

by both drivers and delivery porters. It is the duty of the porter to check his loading sheet against every item placed in his van, and report any discrepancies before leaving. Vans normally leave from 9.45-10 a.m.

Deliveries within approximately three miles of the store are at• present made three times weekly, on Tuesdays, Thursdays and Saturdays, and it is on this work that the battery-elect ricsare mainly employed. Outside this zone, vehicles serve an area extending to Maidenhead, Watford, Tottenham, Bexley, Weybridge and Windsor. Most work, however, falls within 10 miles of Kensington. -Broadly, northern and south-eastern areas are visited on Tuesdays and Thursdays, and northwestern and western areas on Wednesdays and Fridays. Rounds are 'planned to follow a circular plan as nearly as possible, although in the main the driver must decide his route according to the density of. his loading.

The busiest periods of the year are during the five winter months, when the Christmas rush is followed by the winter sales, and at the time of the July sales. At these times van capacity is taxed to the extreme. There is less business after the sales and during most of the summer, but the volume of traffic rarely drops to a serious extent_ The Zeeta vans load at the Kensington bakeries or the factory at Barnes with bread, cakes and confectionery for the shops, cafés and restaurants around London, most of which are situated in the southern and western suburbs. Each van has racks for 100 trays and many of . the later vehicles have roller shutters at the rear. The nature of this work requires an early start and many vans make a ,second delivery to the shops. The remainder are occupied for the •rest of the day on general work.

Mixed Traffic

Dispatching of furniture is done from one bay of the loading bank, and a shuttle service is carried out by one of the Dennis vans between there and Barker's and Ponting's furniture departments. Daily routes are planned to conform closely with the advertised delivery service. The mixed nature of the traffic demands a high standard of work from the driver and his porter, for they know that complaints of damage will arise without constant attention to detail in wrapping, tying and segregating.

Monday is allotted to cleaning and running maintenance, and is the busiest day of the week for the garage in Pembroke Road, about a mile from the main stores and occupying a site together with the furniture depository. Most of the delivery vans are kept overnight in the Derry and Toms building. The remainder, including the Zeeta vans other than those based at Barnes, are

garaged at Pembroke Road, where a certain number of old Ford and Dennis vehicles are held in reserve.

Modern Westalite plant for charging the majority of the battery-clectrics is installed in the garage. There is also charging equipment in the war-damaged electricvan garage near the stores.Although this is still capabla of charging many vehicles it is used for only a few. It is cumbersome by modern standards and outdated by the simple and comparatively trouble-free wall-type chargers.

in due course it is proposed to house all the elect rics at Pembroke Road, more Westalite units being installed to accommodate them. Batteries are given a normal nightly off-peak charge with a balancing charge every weekend during the winter, and one weekend in every month during the summer.

As most of the vans arc in the garage on Mondays. advantage is taken of the occasion to make a general inspection and carry out minor repairs. When a van requires a dock overhaul, arrangements are made for it to be taken off the road at an early opportunity. About 10 vehicles are greased and inspected each day, a Tecakmit 5-ton hoist and a high-pressure lubricating plant of the same make being used for this purpose.

A comprehensive range of equipment is provided for maintenance. A large Tecalemit compressor feeds 12 air lines laid to varidus points around the premises. Workshop tools include a Black and Decker valve refacer and Vibrocentric grinder, a Harvey Frost 30 cwt. floor crane for engine removal, and Ski-Hi, Bradbury and RE. trolley jacks. There is also a heavy-duty floor drill, a light bench drill, a 6-ton mechanical press, a Barker 6-in, lathe, welding plant and Crypton batterycharging equipment.

The efficiency of rebuilt engines is checked.by V.L.C. vacuum and compression gauges. A steel-section bridge for supporting the front ends of vehicles for service attentions is a useful item that was made in the garage, likewise a small trolley containing a battery with extension leads for engine starting. Sparking plugs are cleaned in a Champion unit.

Fordson and Bedford engines are rebuilt in the workshops, power units being removed when fuel consumption becomes relatively excessive. Cylinder-bore wear up to 0.012 in. is compensated by fitting Wellworthy Duaflex piston rings. The next time the engine is taken out it is rebored and the crankshaft reground. This work is undertaken by specialist contractors.

As is usual with delivery vehicles making many stops and starts, there is heavy wear on clutches and starter rings. A tendency for sparking plugs to oil up has been checked by fitting A.C.48 plugs.

Spare dynamos and starter motors are held in stock for all vehicles. Brake shoes are replaced at 10,000 miles with newly faced units. Ferodo and Don bonded shoes are being adopted. Brake-drum liners are fitted when necessary.

Tyres are given special care. A complete record is maintained both for the individual tyres and the sets on each van, and every effort is made to reduce wear to a minimum by careful Maintenance, using the correct tyre for the type of work to be carried out, and frequent reminders to drivers of the importance of maintaining the right pressures. Periodic checks by Michelin

representatives produce excellent results. Tyres are removed for retreading when half the width of the tread pattern has disappeared, particularly good wear and anti-skid .performance having resulted from the Wyresoles process.

All vehicle faults and damage, no matter how trivial, are carefully analysed. Breakdowns are recorded, and the reason for them thoroughly investigated. This adds much to the knowledge of the garage staff in their efforts to avoid trouble by preventive maintenance.

Body paintwork is retouched and varnished every two years. A full range of spares is held in store, use also being made of the Bedford reconditioned-unit exchange plan.

Vehicle costing follows a straightforward but thorough system. Each day, a ledger sheet for each vehicle is completed to record mileage and the cost of wages, petrol, lubricants, tyrcs and maintenance. These are collated monthly and a debit for overhead expenses. divided equally among the various vehicles irrespective of capacity, is put down. Cost per mile run is calculated with further additions for taxation and insurance. An analysis is then prepared from the monthly figures for presentation to the transport manager, Mr. C. H. Turner. M.I.T.A., and the accountants.