T.S. MOTORS ANNOUNCES NEW CHASSIS

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

ANKING, not long ago, amongst

the foremost of commercial

vehicle manufacturers, T.S. Motors, Ltd., Victoria Works, Maidstone, after a period of comparative inactivity, is now favourably situated for recovering its old position in the industry. We are glad to be able to make this statement, and to accompany it by announcing the introduction by the company of a new passenger model, the production of which has commenced.

The concern's well-equipped and modern factory is capable, we are informed, of producing as many as 20 machines a week, and, although it is hardly likely that the output Will reach this number for some time to come, one would hesitate to class as unduly optimistic the company's ambition eventually to work to capacity. .

Bearing the same name as its predecessor—the Express—the new chassis is built to carry a .32-34-seater body and its design fundamentally resembles the earlier machine, which, in respect of first-class workmanship, sound con

B26 • struction and economical operation, enjoyed a fine reputation. There are numerous new features, however, the performance is superior and the whole layout is in accordance with the latest tendencies.

It is available in three forms, model HA39A7, with a four-cylindered petrol engine, having a bore and stroke of

411ins. (108 mm.) and ins. (140 mm.), giving a capacity of 5.115 litres; model 1449A7, also petrol-engined, the dimensions in this case being 41 ins. (121 mm.) by C ins. (152 ED ) —6.97

litres ; and model H4LA7, with a Gardner four-cylindered oil engine-5.578 litres. The T.S.M. double-decker and single-decker chassis, with six-cylindered engines, and the 4-tonners will still be manufactured.

At the present time the maker is concentrating upon the first-named of the three forms in which the new model is produced, and to this the following brief description applies.

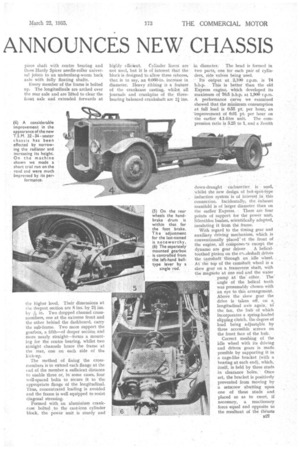

With forward control and a 17-ft. wheelbase, a body space of 23 ft. 11 in. is afforded. The power unit is mounted in a subframe and drives thrclugh a. 14-in. elutch, a fabric-jointed short shaft and a separate gearbox. Thence -the power is transmitted by a two

piece shaft with centre bearing and three Hardy Spicer needle-roller universal joints to an underslung-worm back axle with fully floating shafts.

Every member of the frame is bolted up. The longitudinals are arched over the rear axle and are lifted to clear the front axle and extended forwards at the higher level. Their dimensions at the deepest section are 8 ins. by 2* ins.

by in. Two dropped channel crossmembers, one at the extreme front and the other behind the dashboard, carry the sub-frame. Two more support the gearbox, a fifth—of deeper section and more nearly straight—forms a mounting for the centre bearing, whilst two straight channels brace the frame at the rear, one on each side of the kick-up.

The method of fixing the crossmembers is to extend each flange at the end of the member a sufficient distance to enable three or, in some cases, four well-spaced bolts to secure it to the appropriate flange of the longitudinal. Thus, concentrated loading is avoided and the frame is well equipped to resist diagonal stressing.

Formed with an aluminium crankcase bolted to the cast-iron cylinder block, the power unit is sturdy and highly efficient. Cylinder !inert are not used, but it is of interest that the block is designed to allow three rebores, that is to say, an 0.000-in. increase in diameter. Heavy ribbing is a feature of the crankcase casting, whilst all journals and crankpins of the threebearing balanced crankshaft are 2i ins-. in diameter. The head is formed in two parts, one for each pair of cylinders, side valves being used.

' Its output at 2,300 r.p.m. is 74 b.h.p. This is better than the old Express engine, which developed its maximum of 70.5 b.b.p. at 1,900 r.p.m. A performance curve we examined showed that the minimum consumption at full load is 0.55 pt. per hour, an -improvement of 0.01 pt. per hour on the earlier 4.1-litre unit. The compression ratio is 5.25 to 1, and a Zenith down-draught carburetter is used, whilst the new design of hot-spot-type induction system. is of interest in this connection. Incidentally, the exhaust manifold is of larger diameter than on

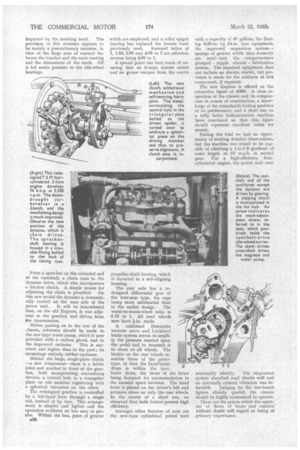

the earlier Express. There are four points of support for the power unit, Silentbloc bushes, scientifically adapted, insulating it from the frame. With regard to the timing gear and auxiliary driving mechanism, which is conventionally placed' at the front of the engine, all conmoneets except the

dynamo are gear drivel? A helicaltoothed pinion on the ce, akshaft drivesthe camshaft-through an idle wheel. , At the top of the camshaft wheel is a slcew gear on a :transverse shaft, with the *magneto at 6rie end and the water pump at *theother.. The' angle of the helical teeth was presumably chosen with an eye to thiS arrangement. Above the Skew gear the drive is taken off, on a longitudinal axis again, ts the fan, the hub of which incorporates a spring-loaded slipping clutch, the degree of load being adjustable by three accessible screws on the front face of the hub.

Correct meshing of the idle wheel with its driving and driven gears is made. possible by supporting it in a cage-like bracket (with a bearing at each end), which, itself, is held by three studs in clearance holes. Once set, the bracket is positively prevented from moving by a setscrew abutting upon one of these studs and placed so as to exert, if necessary, a reactionary force equal and opposite to the resultant of the thrusts imparted by the meshing teeth. The provision of this setscrew appears to be mainly a precautionary measure, in view of the large area of contact between the bracket and the main casting and the dimensions of the studs. Oil is fed under pressure to the idle-wheel bearings.

From a sprocket on the extended end of the camshaft, a chain runs to the dynamo drive, which also incorporates a friction clutch. A simple means for adjusting the chain is provided. On this new model the dynamo is demountably carried on the near side of the power unit. It will be remembered that, on the old Express, it was adjacent to the gearbox and driven from the transmission.

Before, passing on to tne rest of the –hassis, reference should be made to the new-type water pump, which is now provided with a carbon gland, and to

the improved radiator. This is narrower and higher than in the past; its mountings embody rubber cushions.

Behind the large, single-plate clutch —a new component—there is a fabric joint and another in front of the gearbox, both incorporating centralizing devices, a central hole in a triangular plate on one member registering with a spherical extension on the other.

The redesigned gearbox is controlled by a left-hand lever through a single rod, instead of by two. This arrangement is simpler and lighter and the operation rendered no less easy or precise. Within the box, gears of • greater

e28

width are employed, and a roller spigot bearing has replaced the bronze bush previously used. Forward ratios of 1, 1.64, 2.98 and 4.89 to 1 are afforded, reverse being 4.06 to 1.

A special point has been made of ensuring that no fcreign matter enters and no grease escapes from the centre propeller-shaft bearing, which is mounted in a self-aligning housing.

The rear axle has a redesigned differential gear of the four-arm type, the cage being more substantial than in the earlier design. The worm-to-worm-wheel ratio is 5.75 to I. All road wheels now have fin. studs.

A combined Dewandre vacuum servo and Lockheed brake system serves to amplify the pressure exerted upon the pedal and to transmit it to shoes on all wheels. The brakes on the rear wheels resemble those of the proto-type, in that the hand-brake drum is within the footbrake drum, the shoes of the latter being designed for accommodation in the annular space between. The hand lever is placed on the driver's left and actuates shoes on only the rear wheels. in the course of a short run, we observed that both brakes possess high efficiency.

Amongst other features of note are the new-type cylindrical petrol tank with a capacity of 40 gallons, the Dunlop 8.25-in. by 24-in. tyre equipment, the improved suspension system— springs of greater width than formerly are used—and the comprehensive grouped nipple chassis lubrication system. The standard equipment does not include an electric starter, but provision is made for the addition of thit component, if required.

The new Express is offered at the attractive figure of £660. A close inspection of the chassis and its components in course of construction, a knowledge of the remarkable lasting qualities of its predecessors, and a short run on a fully laden demonstration machine have convinced us that this figure should represent excellent value for money.

During the trial we had no opportunity of making detailed observations, but the machine was found to be capable of climbing a 1-in-7.8 gradient of some length at 10 m.p.h. in second gear. For a high-efficiency fourcylindered engine, the power unit runs

(Below) The camshaft and all the auxiliaries except the dynamo are driven by gearing. A slipping clutch is incorporated in the fan hub. An arrow indicates the mesh-adjustment screw, referred to in the text, which positively holds the camshaft-drive idle-wheel carrier. The skew-driven cross-shaft drives the magneto and

water pump.

reasonably silently. The suspension system absorbed road shocks well and no internally created vibration was de tectable. Judging by the test-bench figures already quoted, the chassis should he highly economical to operate.

These are the points which the opera-. tor of fleets of buses and coaches without doubt will regard as being bf primary impOrtance.