• A chance remark by a British Rail official in

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

1982 persuaded the Stirling family to invest in a sizeable yard at Mossend, near Bellshill in Lanarkshire. The main attraction of the site was its rail connection which allowed Peter Stirling to build up a rail/road distribution business.

Billy Stirling recalls that he had to move quickly to secure the site. "We saw a future in developing a proper railhead at Mossend, and quickly realised we had done the right thing."

Since 1961 Stirling had been working closely with British Rail at various sites in the Glasgow area, but the move to Mossend allowed proper terminal facilities to be developed, and today 80% of the company's business is rail-orientated.

The Stirling family started in 1870 as coal merchants, with horse-drawn and eventually motor wagons. Billy Stirling started in the family business in 1952, and brother Gordon joined in 1960 after a period in Canada.

Today, the brothers are the commercial and operational directors of a successful and growing road/rail operation.

The key to that success is Mossend Railhead, a 6ha site next to British Rail's main Scottish marshalling yard, with direct links to the rest of the BR system. Scotland's two principal motorways, the MS and the M74, are also close by.

"What makes Mossend different is that it is an open railhead," says Billy Stirling. "While we are a road haulage company, and you will see our vehicles all over the site, we are happy to allow other hauliers to load and unload.

"Many companies already benefit from this service — British Oxygen, Distillers, Freightliners and Scottish Fruit Merchants are just a few," he adds.

A road/rail operation of this kind only became really practical when BR moved from vacuum-braked wagons, which restricted their use to overnight hauls on main lines. Now, with air-braked wagons up to 100 tonnes, the Mossend railhead is serviced three times a day and, when necessary, during the night.

"We get great co-operation from railway staff," Billy Stirling explains. "There's none of the hard-line 'not-my-job' attitude at Mossend. The marshalling yard is staffed round the clock, and we find that shunters are prepared to move wagons at any time if it helps to keep the railhead going."

Stirling's six-day working week ensures a quick turn-round, particularly important for British Oxygen tanks or perishable fruit. A load delayed en route on a Friday, which would otherwise sit until Monday, can be delivered by Stirlings on Saturday. BR's Total Operation Processing System (TOPS) network allows etch day to be pre-planned. Twice-a-day telex printouts are received, showing the wagons en route to Mossend, their origin, commodity carried and consignee.

On average, 40-50 35-tonne wagons can come in overnight, although on occasion the total can exceed 200. "That's where TOPS is a life-saver," says Billy. "We know what is coming and we can arrange staff and trucks to be ready for the transfer and distribution."

Most of Stirling's customers are within easy reach of Mossend, and drivers can often squeeze three or four return trips into a working day. Billy's son Peter is terminal manager, and has the daunting task of keeping the wheels turning. "I reckon 65% of our work is within a 15mile radius, and for us a long-haul is the 77-mile trip to Guardbridge in Fife, with china-clay for paper-making. Needless to say, our drivers enjoy the occasional long trip," he says, "and we try to share this work around."

Most of the long-haul business is handled by rail. "We believe in the roadirail principle, and feel that rail should handle what it does best — the large longdistance loads — and we can concentrate on getting the goods from the Railhead to the customer, and vice-versa," says Billy Stirling. The only real long-distance haulage the company handles is specialist work that is unsuited to rail, like the 15m piles recently carried north for the new Dornoch Bridge.

Large quantities of steel pass through Mossend, not from the nearby giant British Steel Ravenscraig plant, but mostly coming north by rail from BSC and private steelworks in England and Wales as billets, bars, coil, rod and sections, for steel stockholders and fabricators.

Over 300 metres of rail track can be handled by a crane gantry with four 10tonne cranes capable of 20-tonne tandem lifts. A special attachment allows quick loading and unloading of billets, and adapted trailers are used to deliver steel rod in coils.

China clay is another important commodity handled at Mossend, much of it corning north from Cornwall by rail for onward transfer within Scotland. One of the three bulk bins on site is reserved for bulk china clay, with a reception hopper capable of serving several different kinds of clay. The other hoppers, each with 350 tonnes capacity, allow for rapid discharge of bottom-door wagons.

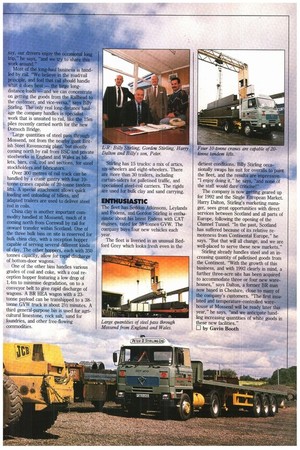

One of the other bins handles various grades of coal and coke, with a coal reception hopper featuring a low drop of 1.4m to minimise degradation, on to a conveyor belt to give rapid discharge of wagons. A BR HEA wagon with a 23tonne payload can be transhipped to a 38tonne GVW truck in about 21/2 minutes. A third general-purpose bin is used for agricultural limestone, rock salt, sand for foundries, and other free-flowing commodities. Stirling has 15 trucks: a mix of artics, six-wheelers and eight-wheelers. There are more than 30 trailers, including curtain-siders for palletised traffic, and specialised steel-coil carriers. The rigds are used for bulk clay and sand carrying.

The fleet has Seddon Atkinsons, Leylands and Fodens, and Gordon Stirling is enthusiastic about his latest Fodens with CAT engines, rated for 38 tonnes GVW. The company buys four new vehicles each year.

The fleet is liveried in an unusual Bedford Grey which looks fresh even in the

dirtiest conditions. Billy Stirling occasionally swaps his suit for overalls to paint the fleet, and the results are impressive. "I enjoy doing it," he says, "and none of the staff would dare criticise!"

The company is now getting geared up for 1992 and the Single European Market. Harry Dalton, Stirling's marketing manager, sees great opportunities with direct services between Scotland and all parts of Europe, following the opening of the Channel Tunnel. "In the past, Scotland has suffered because of its relative remoteness from Continental Europe," he says. "But that will all change, and we are well-placed to serve these new markets."

Stirling already handles steel and an increasing quantity of palletised goods from the Continent. "With the growth of this business, and with 1992 clearly in mind, a further three-acre site has been acquired to accommodate three or four new warehouses," says Dalton, a former BR man now based in Cheshire, close to many of the company's customers. "The first insulated and temperature-controlled warehouse at Mossend will be ready later this year," he says, "and we anticipate handling increasing quantities of white goods in these new facilities." Li by Gavin Booth